Installation guidelines

This Formica LifeSeal Worktop Installation and Maintenance leaflet is for guidance only. Prior to installation, please

check the Formica LifeSeal Worktop meets your needs with regards to colour, surface finish, size and thickness. Please

inspect the worktop for any damage or defects before any work commences, as an installed worktop will be seen as

having been accepted and no liability will be accepted for its removal and/or replacement. PG Bison cannot accept re-

sponsibility for final fitting of your worktop and no fitted claims will be entered into.

Measuring

Marking can be done with a soft pencil either on the face of the worktop, if using a hand saw, or on the back if using a

power saw. Before cutting, check measurements.

Preparation

The worktop should be adequately supported during all cutting, drilling or sawing operations. All cutting tools should be

sharp and safety goggles should be used whenever cutting the worktop.

NB: For your safety please follow instructions supplied by the hand/power tool manufacturer. Ensure all cutting/drilling

tools are sharp and safety goggles are used at all times whenever cutting/drilling into your worktop.

Cutting

If using a HANDSAW (min 10/12 teeth per inch)

1. Using a soft pencil, mark your cutting guide line on the LAMINATE FACE of the worktop.

2. With the laminate face UPWARDS, start sawing from decorative, profiled edge, keeping your saw at a low

angle.

If using an ELECTRIC SAW

1. Using a soft pencil, mark your cutting guide line on the UNDERSIDE of the worktop.

2. With the laminate face DOWNWARDS, start sawing from decorative, profiled edge. Make sure you protect

the laminate surface from scratching underneath.

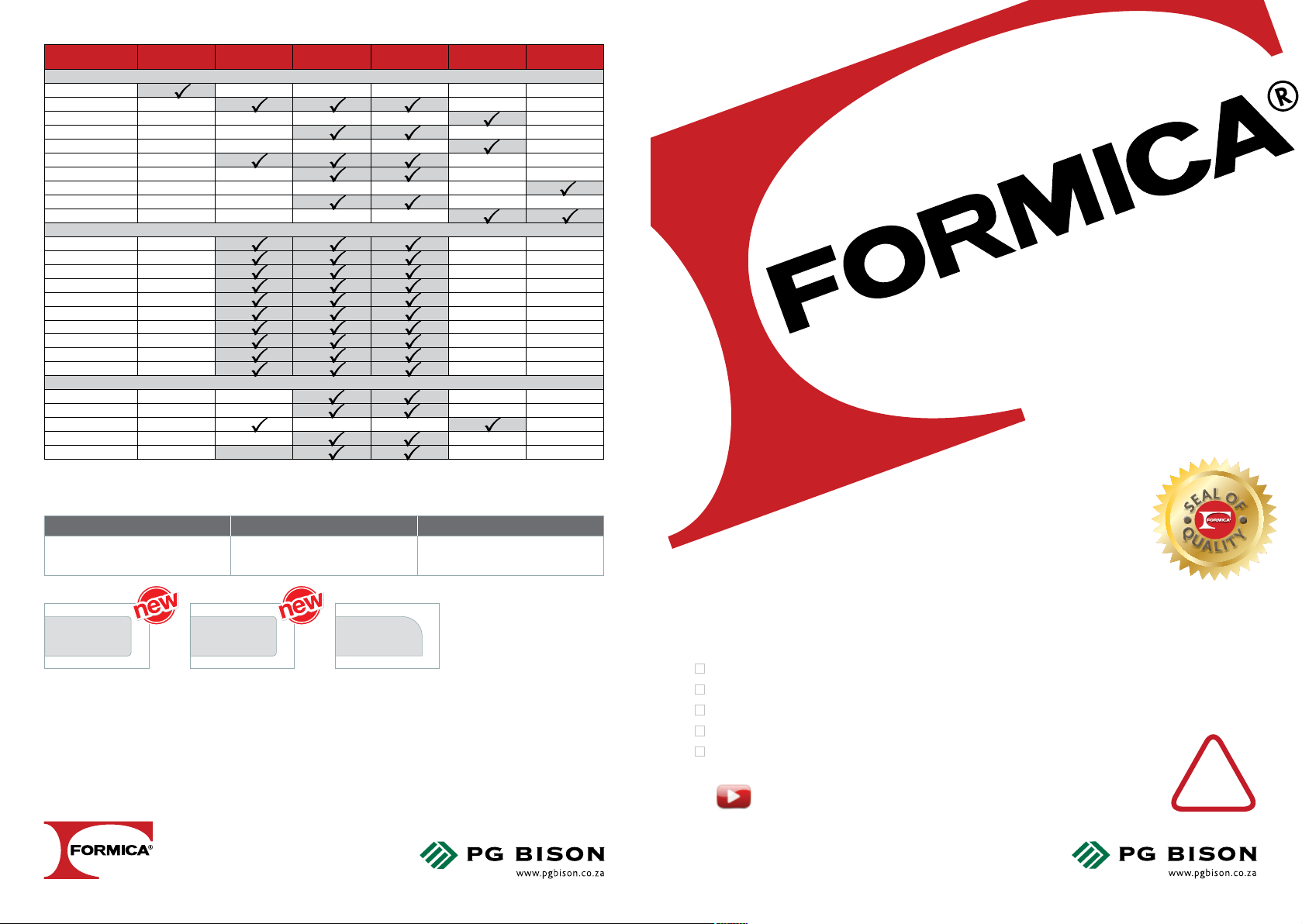

WORKTOP INSTALLATION INSTRUCTIONS

Worktop face up Worktop face down

Drill and drill bits Soft pencil

and cloth Measuring

tape Silicone sealant

and contact

adhesive

PlaneElectric/hand or jig saw (min 10/12 teeth per inch) Exterior grade

varnish and

paintbrush

Tools & materials required

Making cut-outs

All cut-outs should be carefully measured and clearly marked. Working from the decorative face drill through all the

corners using a 12 mm drill bit. This allows access for the jig saw blade when cutting around the cut-out and eliminates

sharp internal corners (min radius = 6 mm) that can lead to cracks forming in the laminate surface. It is recommended

to leave at least 250 mm between cut-outs and from the cut-out to the edge of your worktop. A minimum of 50 mm is

recommended from the edge of the cut-out to the front and back edges of the worktop. After the cut has been made

check the hob or sink for size.

Before finally fitting your hob and sink ensure that all exposed edges of the chipboard are sealed with two coats of an ex-

terior grade varnish. It is also advisable to further protect the hob cut-out by covering the exposed edge with aluminium

tape to prevent heat affecting the cut-out. It is also recommended to apply two coats of exterior grade varnish to the

underside of your worktop, 50 mm wide around all the edges.

NB: Adhesives, sealants, cleaning fluids, etc., always follow the instructions on the label.

Sealing

Where pipes are to be brought up through the worktop, a 2-3 mm allowance for expansion/contraction should be main-

tained around the pipe. All exposed edges, including the exposed particle board in the cut-outs and joint must be sealed

with two coats of exterior grade varnish.

Edging & finishing worktops

Ensure the edge is flat, clean and dust free. Using a small paint brush, apply two coats of contact adhesive to the cut edge

and one coat to the laminate edging. Allow to dry for 15-20 minutes. Bond edge to the board using as much pressure as

possible, using a dry cloth to avoid cutting your hands on the edge of the laminate.

Cleaning

General cleaning of the surface requires only a damp cloth and a mild detergent or non-abrasive cleaner diluted in warm

water. Abrasive scouring powders, creams and even polishes should all be avoided. For the textured surface, a soft nylon

nailbrush can be used to ensure a more thorough cleaning. Potentially persistent stains should be removed immediately.

NB: Remember to thoroughly clean off any residue cleaning agent as build-up will cause stickiness.

THINGS TO DO THINGS TO AVOID

To prevent damage from hot objects, use heat resistant mats

or boards on the surface of the worktop. Always use ashtrays

for cigarettes.

Never place hot objects from the oven, hob or microwave

directly onto the laminate surface since this may lead to

blistering.

Also do not put other hot objects, such as burning cigarettes

or hot irons, directly onto the laminate surface as this will burn

the surface.

Always use a chopping or cutting board for any cutting during

preparation of food or any other cutting / chopping activity.

Some crockery items, kitchen utensils and other objects sliding

across your worktop will produce fine scratches in the laminate.

Avoid sliding rough based objects across the surface.

Never cut foodstuffs directly on the laminate surface.

Wipe spilt liquids away from joints and cut-outs immediately.

Ensure that all inset appliances are properly sealed with a

suitable exterior grade varnish.

Moisture will not harm the laminate surface itself but it is

advisable to wipe away any spillages as soon as possible.

The critical areas are around joints and cut-outs.