Page 2of 9

Initial Set-Up Procedure:

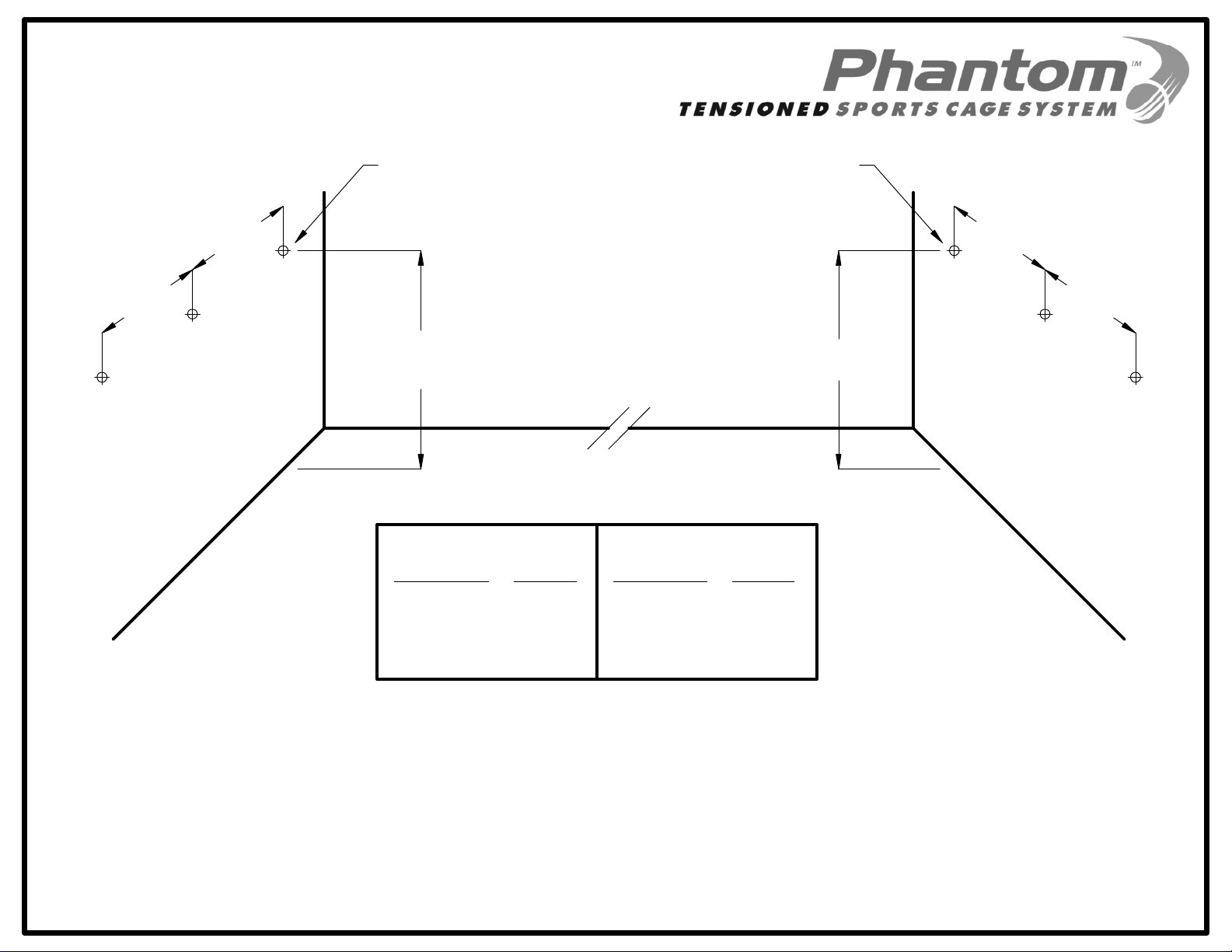

1. Determine which wall in your facility to define as the Tensioning Wall and which

to define as the Anchoring Wall (see Figures 1-1 and 2-1, or 4-1 for Short-Span

Systems). The Tensioning Wall will have the 2:1 Tensioning Assemblies

attached to it with tensioning halyards hanging down to the floor. These halyards

can be gathered and pulled to the side, or lifted and hung out of reach if needed.

This should be taken into consideration so as to avoid interfering with doorways,

etc. The same is true of the Anchoring Wall for Short-Span Systems as the

anchoring halyards will also hang down and must connect to the Rope Cleats.

2. For the initial set-up, position and install the appropriate wall anchors and

eyebolts according to Figure 1-1 prior to attaching the tensioning hardware. Be

sure to account for any adjustment needed to the mounting height on the

Tensioning Wall as noted in the chart at the bottom of Figure 1-1 – this is based

on your wall span.

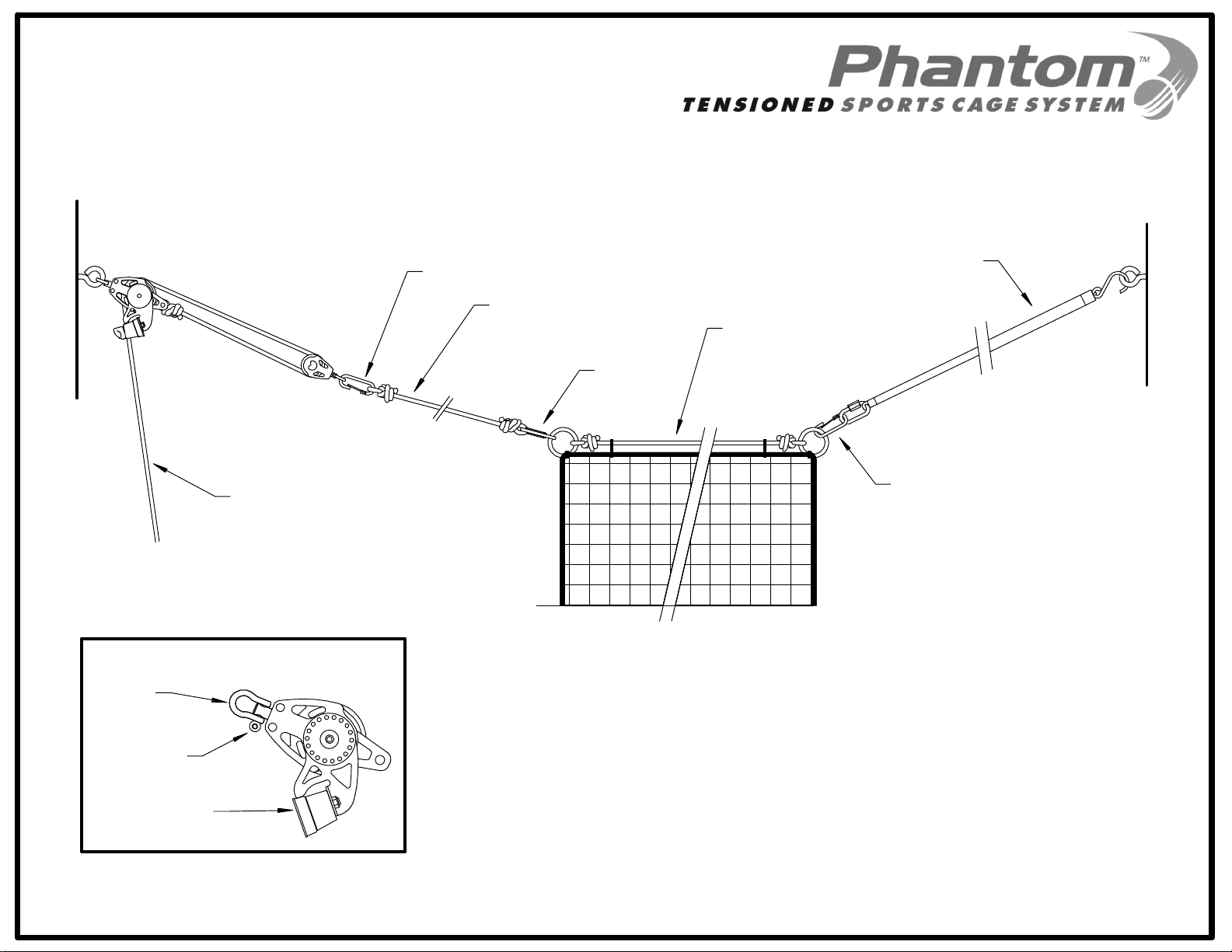

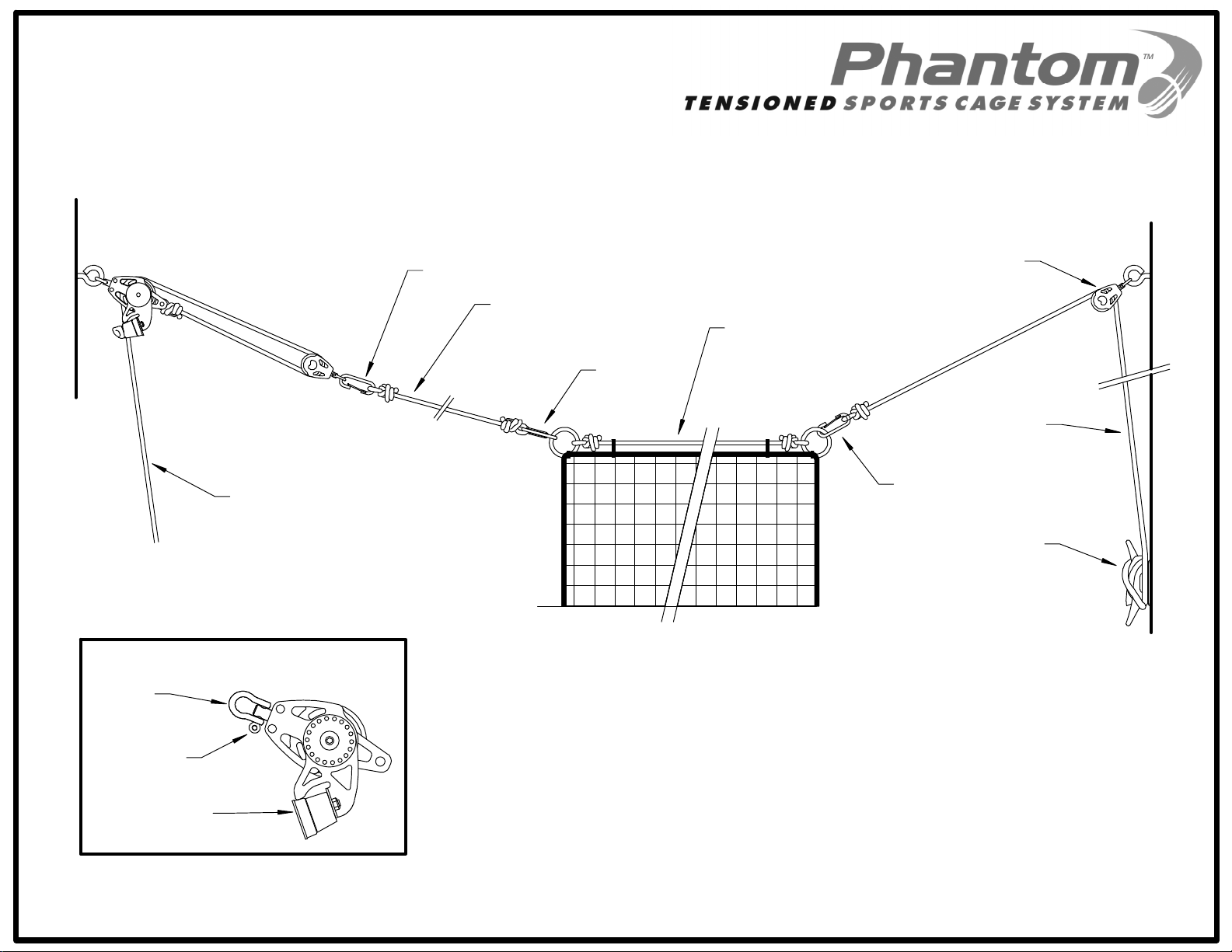

3. Once all eyebolts are installed, attach one Tensioning Block to each eyebolt on

the Tensioning Wall by unscrewing the clevis pin to remove the clevis (see Inset

“A” on Figure 2-1). You may need pliers to loosen the pin initially. Hang the

clevis onto the eyebolt, re-insert the pin to attach the Tensioning Block, and

tighten by hand. Make one last 1/4 turn with the pliers to ensure it is secure.

4. While holding onto the bit clip at the end of the 2:1 Tensioning Assembly, pull the

halyard down towards the floor. Be sure the halyard is not engaged in the cam-

lock and can move freely through the Tensioning Block. Attach the bit clip to the

halyard itself on the LOWER side of the knot that is located 9 feet from the end of

the halyard. The bit clip should be attached here and the 2:1 Tensioning

Assembly stored in this fashion at all times when not in use. This is done to

prevent the bit clip from accidentally drawing back up to the Tensioning Block

and out of reach. The knot has been intentionally placed in the halyard for you

for the same purpose – to prevent the end of the halyard from sliding up and out

of reach. Repeat Steps 3-4 for each of the other eyebolts on the Tensioning

Wall.

5. Lay the cage net out and stretch it across the floor with the steel rings extended

towards each wall. The three Tensioning Cables should be left resting on top.

If you received Reach Poles with your shipment, proceed to the following section

entitled, “Anchoring Wall Attachment for Standard-Span Systems”.

If you received Anchor-End Blocks with anchoring halyards and rope cleats,

continue to Step 6.