4” Executive Recessed Installation Manual

-2 of 8 –

Version 2. – 06/11/09

LIf the above is not possible, it is

recommended to build a temporary box to

replicate the agreed upon cavity size and write

“RECESSED ROLL SCREEN GOES

HERE”. In this temporary cavity, you can

also indicate where the electrical service is to

be located, and any other service information

that the other sub-trades on site may require.

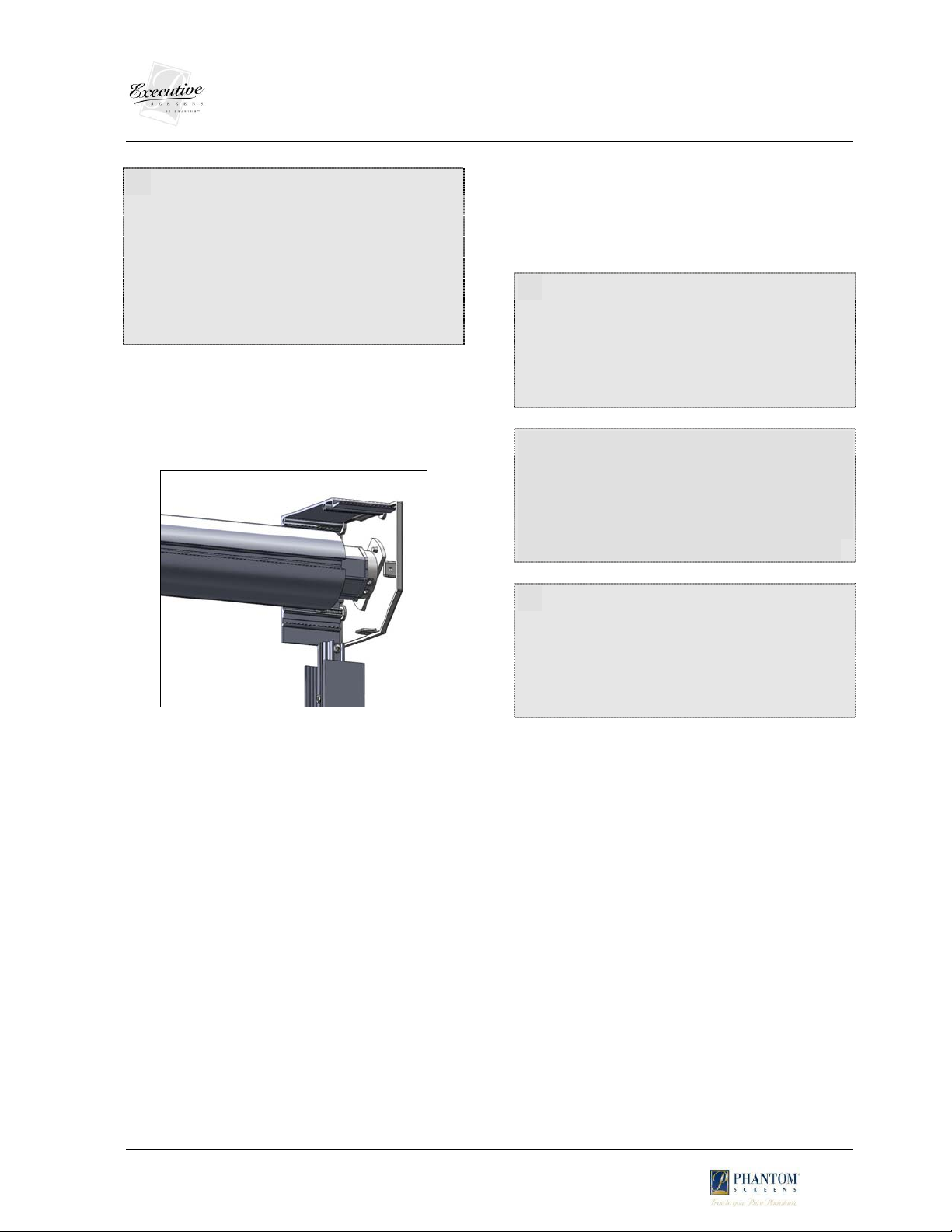

Determine the location where the roller

mounting brackets will be installed in the

cavity. Be sure to pre-drill for mounting holes

(minimum of 3) into each bracket.

Recessed roller mounting brackets

Determine where the electrical wire will be

routed and make sure the wire is on the

correct side of the roller before it is installed.

Depending on your wiring, you may also want

to drill out the bracket for the wire with a

3/8” drill bit.

Mount the pivot side bracket into the cavity.

Slide the motor end cap onto the motor

bracket (the two pins on the end cap mate to

the 2 holes in the bracket attached to the

motor) – ensure the limits face down, and the

motor wire faces the back corner of the

bracket.

While holding the motor end cap bracket

onto the motor (and holding motor into insert

at the same time) install the roller assembly by

inserting the idler bushing onto the post on

the bracket and then lift the assembly up and

secure the motor side bracket in place.

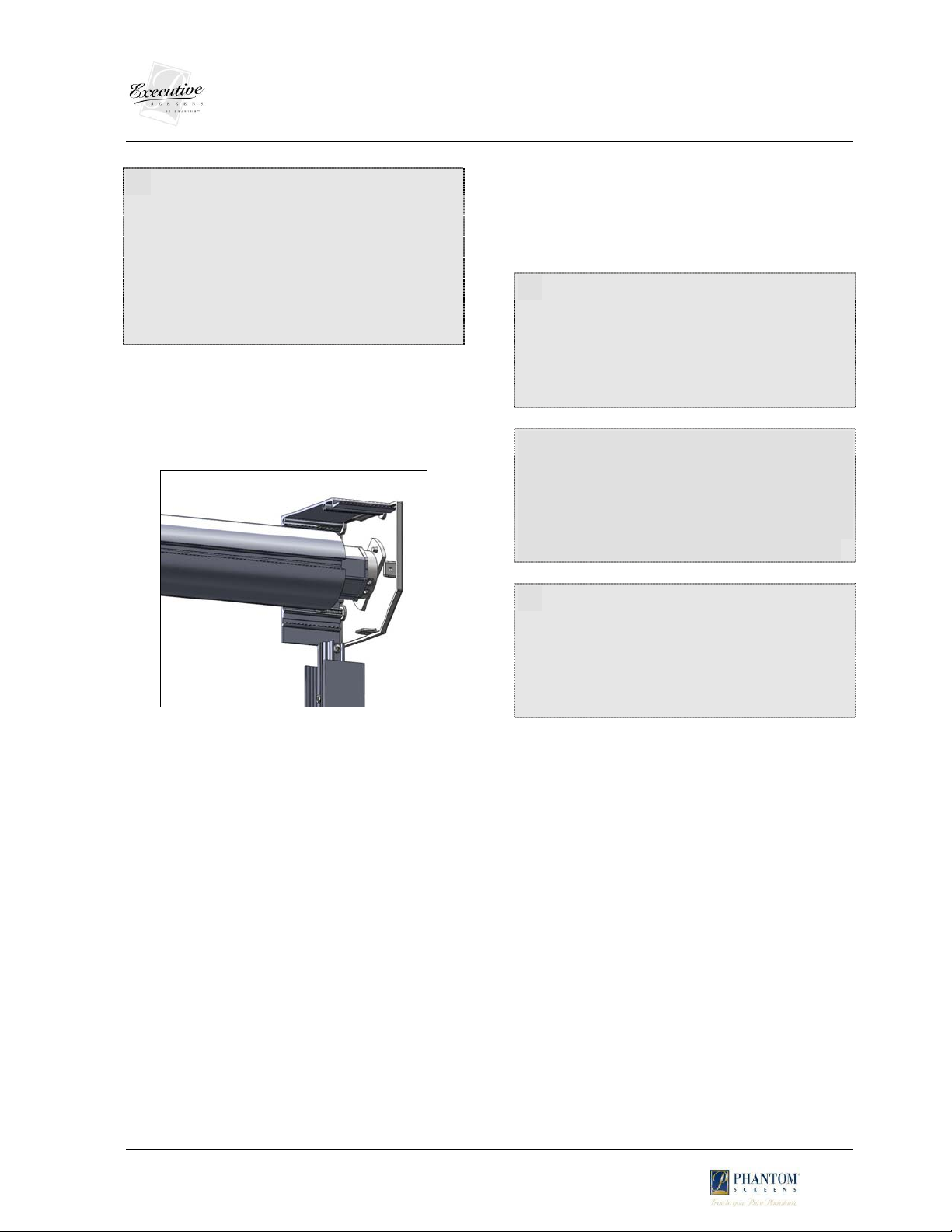

LThe roller must be installed level to

ensure proper roll up so you may need to

shim as needed to achieve this. There should

be no more than 1/16” of side to side

movement in the roller, so you may need to

adjust the bracket location as needed.

LIf there is over 1/16” but less than

3/16” of side to side movement in the roller,

rather than moving a bracket, it may be easier

to remove the screw securing it in and slide

the plastic bushing out of the idle insert by a

MAXIMUM of 1/8” and re-secure in place.

LThe screws through the roller mounting

brackets will be holding the entire weight of

the unit, do not undersize these fasteners

and be sure to continue to support the roller

assembly until you have installed the roller

mounting brackets completely.

After the roller assembly has been installed

make sure there is a drip loop in the electrical

cord leading from the motor so water cannot

back flow into the unit and damage the

motor.