SRG‐4600OVERVIEW

TheSRG‐4600isaportable,lithium‐ionbatterypoweredinstrumentusedforcheckingsurfacefinishwiththemeasured

valuesdisplayedonadigitalreadout.Thisinstrumentcanbeutilizedinalaboratorysetting,ashopinspectionarea,or

whereveron‐sitesurfaceroughnesstestingisrequired.

Note:

Althoughthisinstrumentisdesignedandbuilttowithstandtherigorsofhandlingandusage,itisasensitiveprecision

instrumentandshouldbetreatedwithcaretoassuremeasurementaccuracyandreliableperformance.

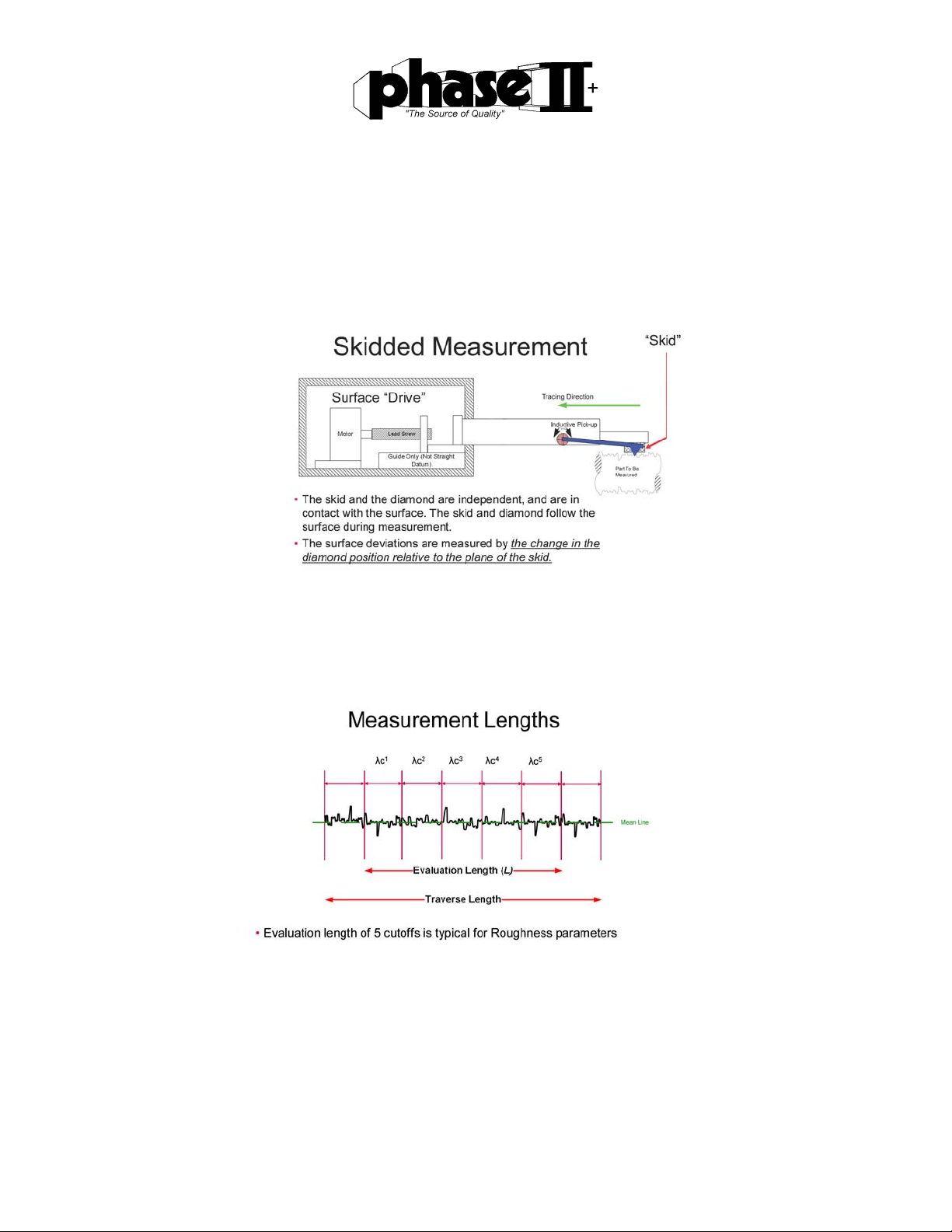

Measurementprinciple:Skidtypesurfaceroughnesstestersarecommoninstrumentsusedontheshopfloor.Adiamondstylus

istraversedacrossthespecimenandapiezoelectricpickuprecordsallverticalmovement.Peaksandvalleysarerecordedand

convertedintoaknownvalueofagivenparameter.

FeaturesofSRG‐4600

9parameters:Ra,Rq,Rz,Rmax,Rt,Rs,RSm,Rmr,RPc

Highaccuracyinductancepickup;

FourfilteringmethodsofRC,PC‐RC,GAUSSandD‐P;

CompatiblewithfourstandardsofISO,DIN,ANSIandJIS;

Canstore20setsofmeasurementsresults

128×64dotmatrixLCDdisplaysallparametersandgraphs;

Dataprocessingwithhighspeedandlowpowerconsumption;

Built‐inhighcapacitylithiumionchargeablebattery.Consecutiveworktimeislongerthan20hours;

CanbeconnectedtoyourPCprintertoprintallparametersandgraphs;

Built‐instandardUSBinterfaceenablescommunicationwithPC;

Automaticswitchoff,memoryandvariouspromptinstructions;

Optionalprinter,analysissoftwareandmeasurementplatform.

Measuringrange ZAxis(Vertical) 160μm

XAxis(Horizontal) 17.5mm

Resolution ZAxis(Vertical) 0.01μm/±20μm

0.02μm/±40μm

Measurementitem Parameters Ra,Rq,Rz,Rmax,Rt,Rs,RSm,Rmr,RPc

Standard ISO,ANSI,DIN,JIS

Graphic Roughnessprofile,Materialratiocurve,Direct

profile

Filter RC,PC‐RC,Gauss,D‐P

Samplinglength(

r) 0.25, 0.8, 2.5mm

Assessmentlength(

n) Ln=

r×nn=1‐5

PickupPrinciple Differentialinductance

Stylus NaturalDiamond,90°coneangle,5μmtip

radius

Force <4mN

Skid Ruby,Longitudinalradius40mm

Traversingspeed

r=0.25,Vt=0.135mm/s

r=0.8,Vt=0.5mm/s

r=2.5,Vt=1mm/s

ReturnVt=1mm/s

ccurac

Lessthanorequalto±10%

Repeatabilit

Lessthanorequalto6%

Powersuppl

Buil

‐inLithiumionbattery,ACadapter

8.4V,800mA

L×W×H119×47×65mm

WeightApprox. 380g