1

1Overview 3

1.1Advantages3

1.2MainApplication&TestingRange.....................................................................3

1.2.1MainApplication...................................................................................................3

1.2.2TestingRange.........................................................................................................3

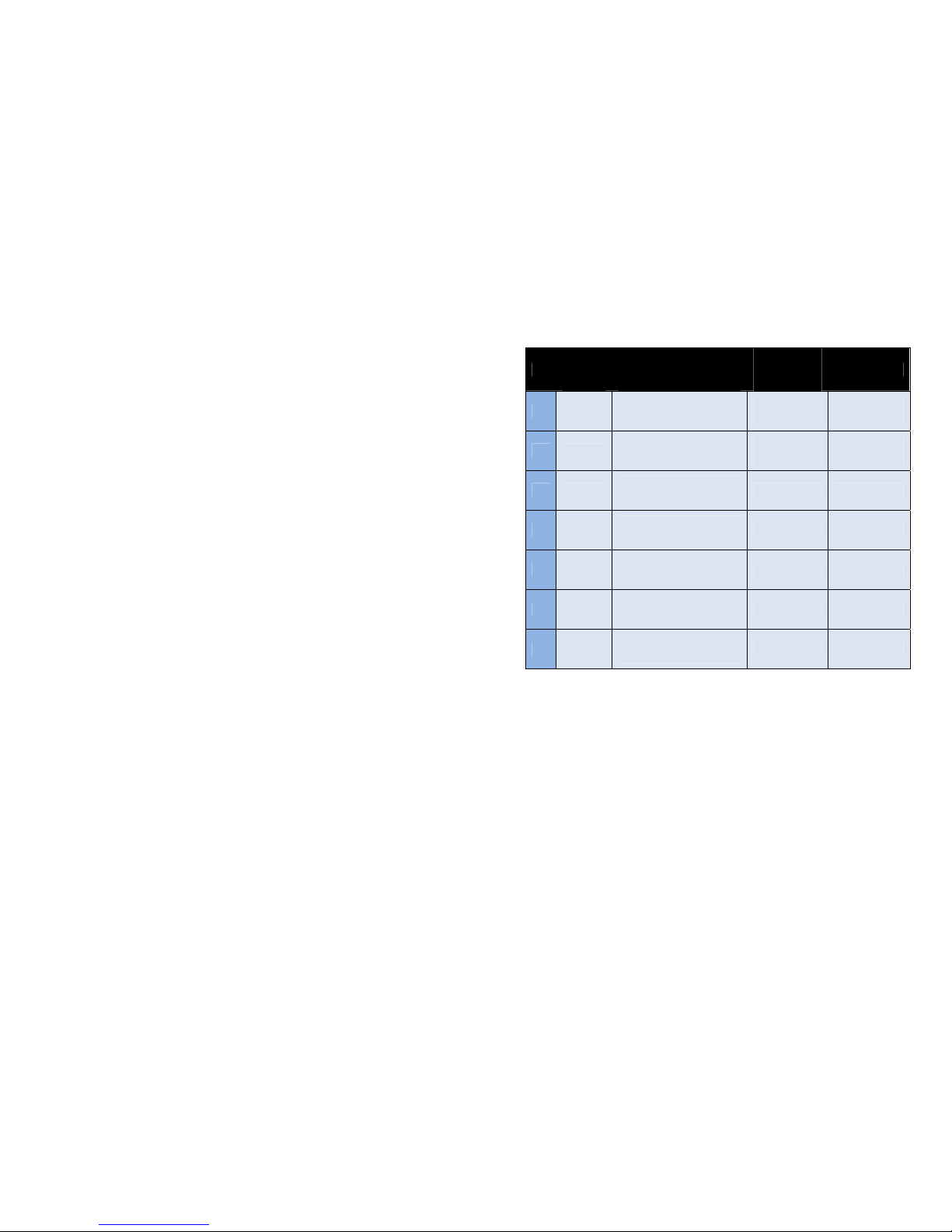

1.3TechnicalSpecifications........................................................................................3

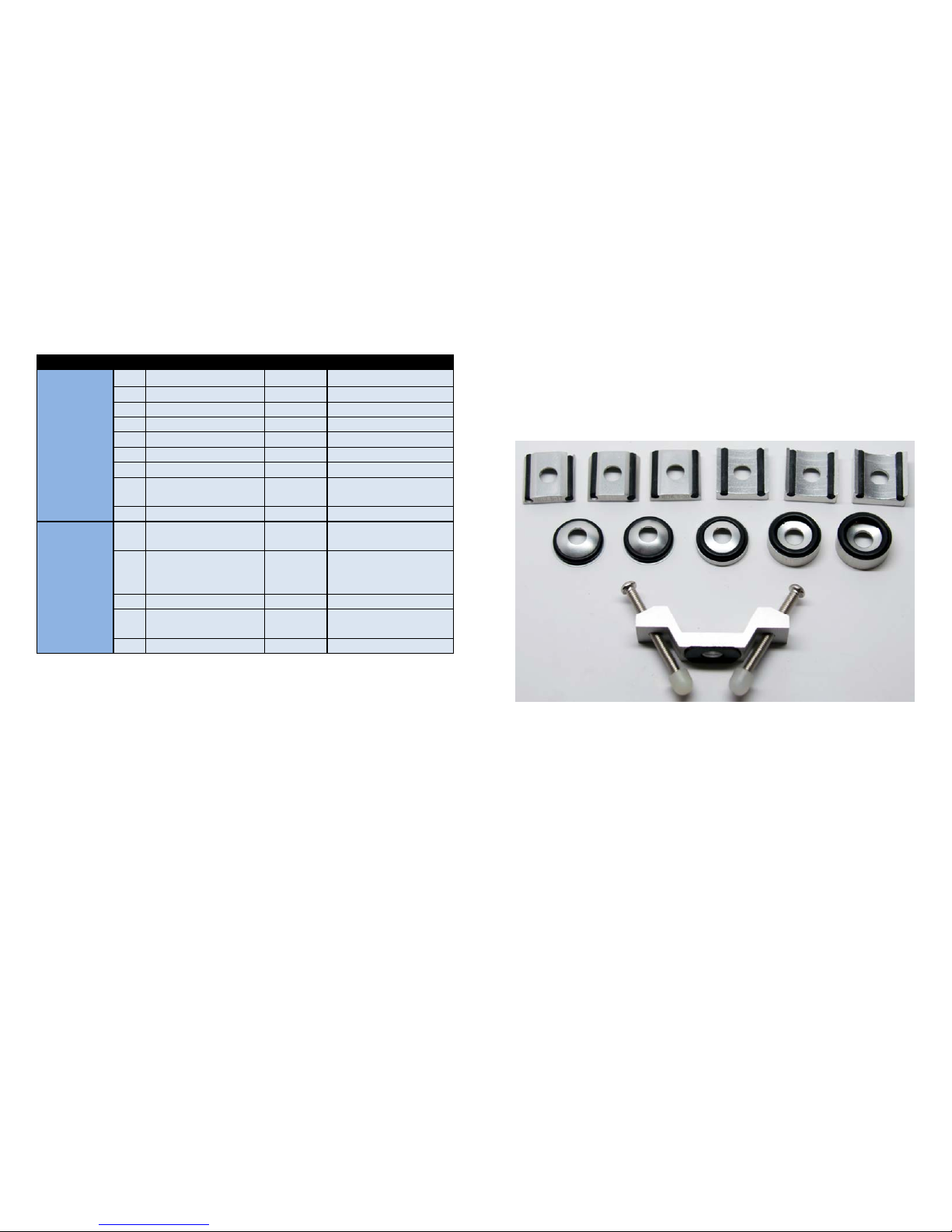

1.4Configuration.............................................................................................................4

1.5WorkingConditions................................................................................................5

2StructureFeature&TestingPrinciple5

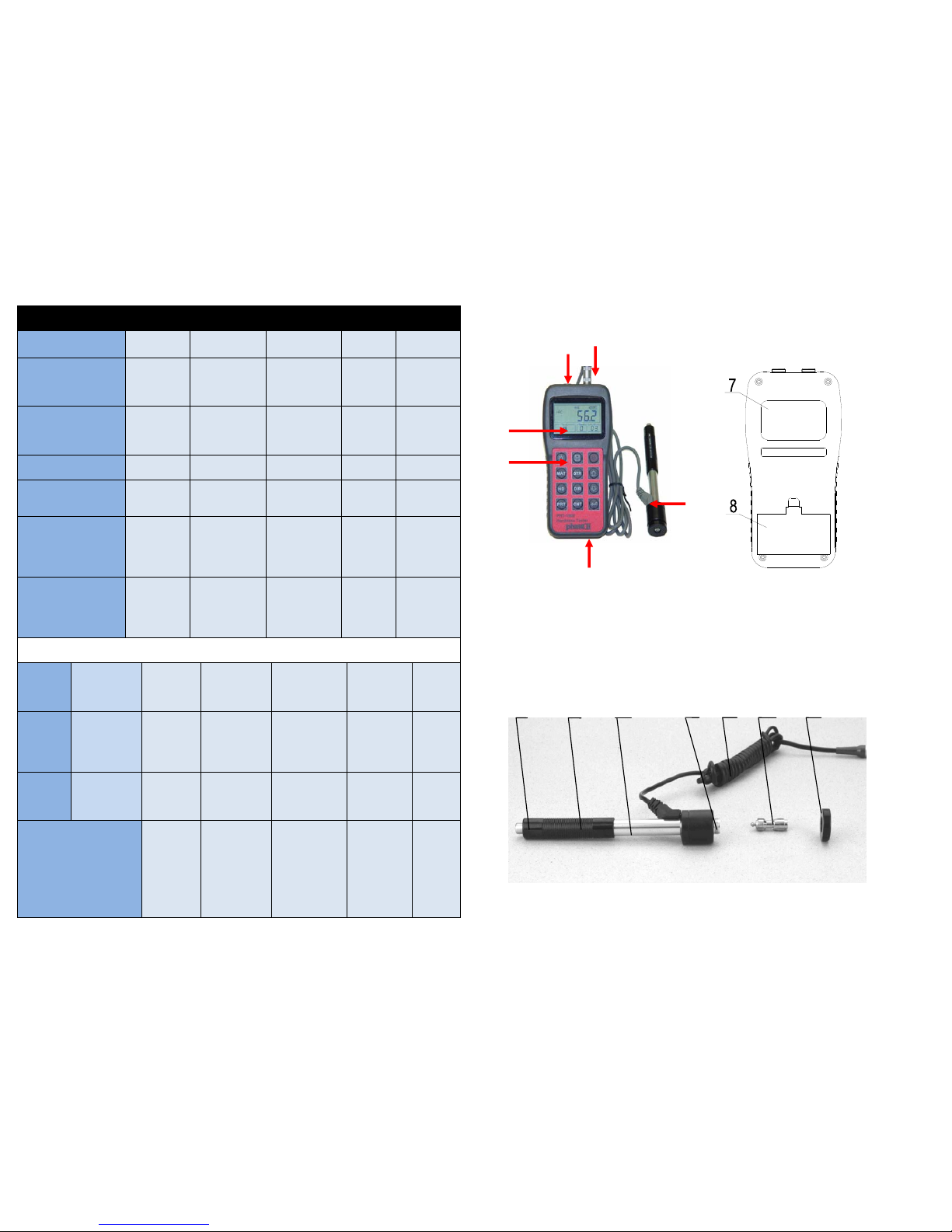

2.1StructureFeature......................................................................................................6

2.1.1DTypeImpactDevice.........................................................................................6

2.1.2DifferentTypesofImpactDevice..................................................................7

2.2MainScreen................................................................................................................7

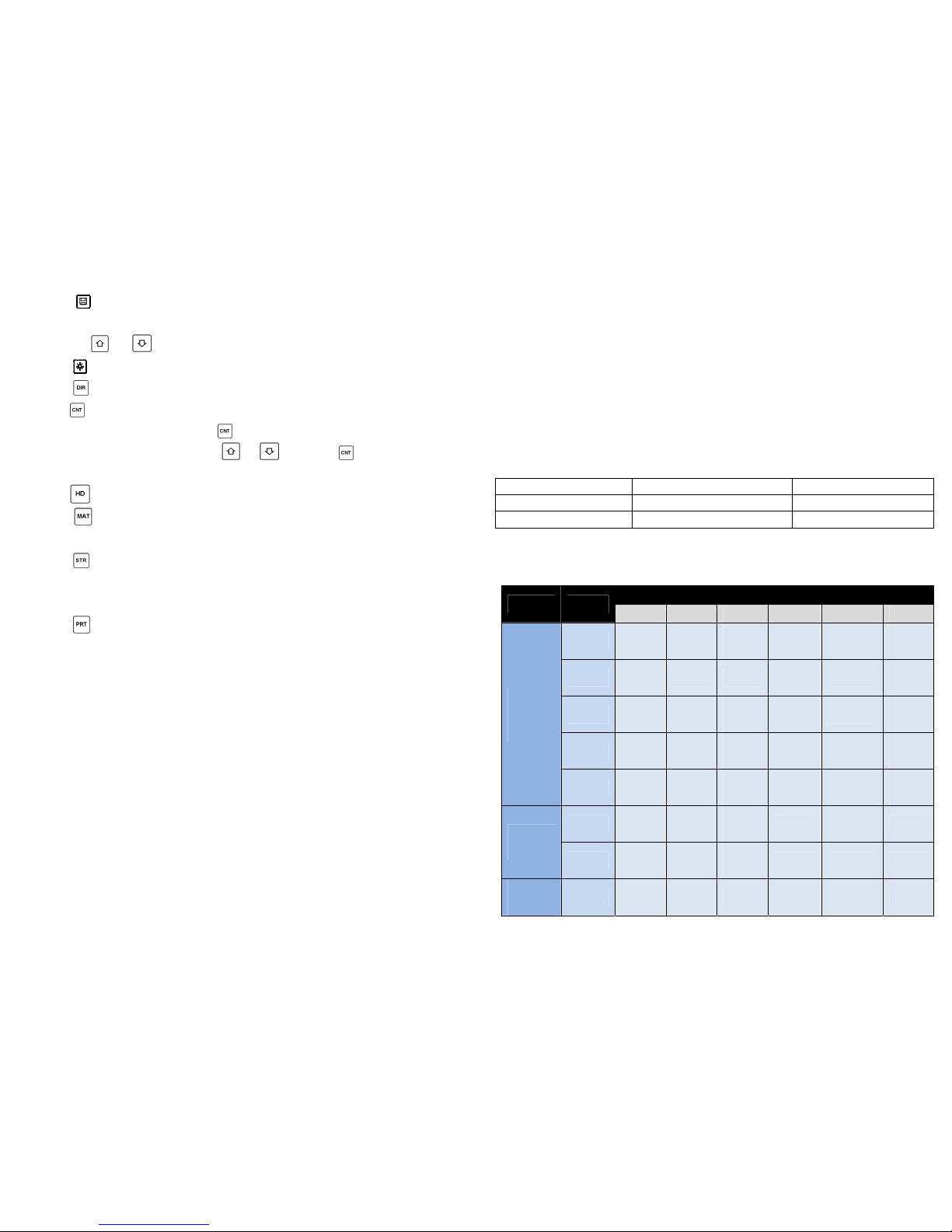

2.3KeypadDefinitions..................................................................................................8

2.4LeebHardnessTestingPrinciple........................................................................9

3Preparation 10

3.1InstrumentPreparationandInspection......................................................10

3.2ImpactDeviceSelection......................................................................................10

3.3PreparationoftheSampleSurface.................................................................11

4TestingProgram 12

4.1Start‐Up......................................................................................................................12

4.2Loading......................................................................................................................12

4.3Localization..............................................................................................................12

4.4Testing........................................................................................................................12

4.5ReadMeasuredValue..........................................................................................13

4.6Notification..............................................................................................................13

5OperationDetail13

5.1PowerOn/Off..........................................................................................................13

5.2MaterialSetting......................................................................................................14

5.3Hardness/Strengthtesting.................................................................................15

5.4ImpactDirectionSetting.....................................................................................15

5.5AverageTimesSetting.........................................................................................15

5.6Datalogging..............................................................................................................15

5.6.1Viewingstoredfile/Group.............................................................................15

5.6.2Clearingselectedfile/Group..........................................................................16

5.7PrintReport.............................................................................................................16

5.8SystemReset...........................................................................................................16

5.9ELBacklight.............................................................................................................17

5.10AutoPowerOff....................................................................................................17

5.11BatteryReplacement.........................................................................................17

5.12ConnectingtoaComputer..............................................................................17

5.13ErrorCodeReference....................................................................................................17

26

Effective:December6,2011

WarrantyPolicy:

Allportableandstationarymaterialtestinginstrumentsmanufacturedfor/by

PhaseIIshallbefreefromdefectsinmaterialandworkmanshipforaperiod

of1to5fullyears(dependinguponmodel)fromdateofpurchase.Partsfound

tobedefectiveshallbereplacedorrepairedatPhaseII’ssolediscretion.

ProductsfoundbyPhaseIItobemisused,abusedorneglectedarenot

coveredunderthiswarranty.Partsnotcoveredbythiswarrantyarenormal

wearandconsumableitemssuchas(butnotlimitedto)impactballs,impact

bodies,diamondindentors,carbideballindentors,impactsprings,cablesand

connectors,batteries,diamondstylus,contactprobes,etc.

Consumable(wearable)itemssuchascablesandprobeshavea90day

warrantyfromdateofpurchase.

Thiswarrantyisexclusiveandinlieuofallotherwarrantieswhetherwritten,

oralorimplied,includinganyimpliedwarrantiesormerchantabilityor

fitnessforaparticularpurpose.InnoeventshallPhaseIIbeliableforany

incidental,specialorconsequentialdamagesofanynature.

ReturnPolicy:

AllPhaseIIproductsmusthaveauthorizationpriortoreturn.

Ifproductisnotacceptableforanyreasonincludingapplicationissuesand

demonstrations,authorizationforreturnmustbeobtainedwithin10daysof

receiptofproduct.Unitmustbeinsamenewconditionitwasreceived.

Failuretodosowillresultinanautomatic15%restockingfee.

Returnsafter30dayswillnotbeaccepted.