CONTENTS

Page 1Table of Contents

SECTION

1

2

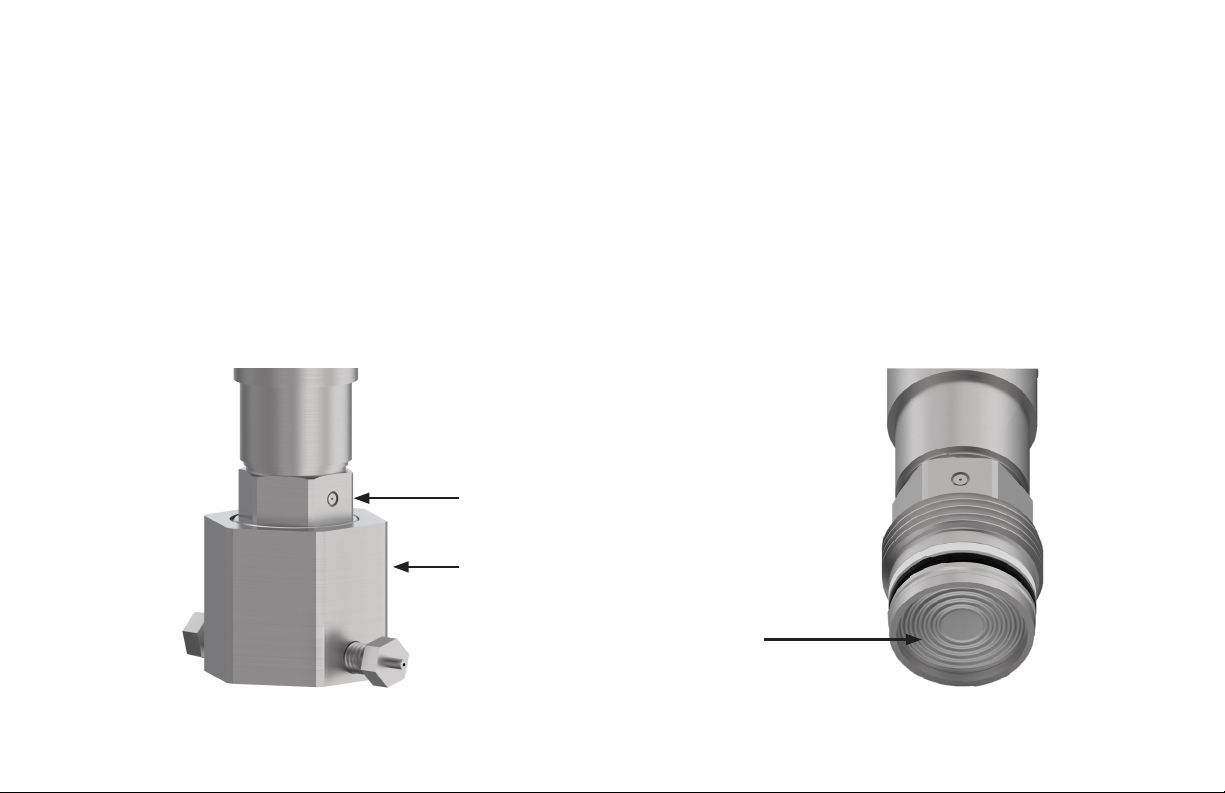

MECHANICAL INSTRUCTIONS

2.1 Connecting User Fluid System to Presssure Sensor ........................................................

2.2 Consumables ..............................................................................................................................................

2.3 Microcap Attatchment .........................................................................................................................

XTALX LUQS1 SPECIFICATION SHEET

3.1 Specification Hightlights ....................................................................................................................

3.2 Mechanical Specifications ................................................................................................................

3.3 Electrical Specifications ......................................................................................................................

3.4 Oscillator Specifications .....................................................................................................................

3.5 Additional Specifications ...................................................................................................................

3.6 LUQS1-10000-85 Specification Drawing .................................................................................

PAGE

3-4

5-6

7-8

9

9

9

9

9

10