Telco Sensors SpaceMaster Series User manual

SMRR 7000-IO - USER MANUAL EN

SpaceMaster Series

Photoelectric retro-reflective sensors with IO-link

Website: www.telcosensors.com

Warning

V 1.0 Part Number: L40-0666220939

E-Mail: info@telcosensors.com

This device is not to be used for Personnel Protection in Machine

Guarding Safety applications. This device does not include the self-

checking redundant circuitry necessary to allow its use in personnel

machine guarding stand-alone safety applications.

October 2021 edition

Made in Denmark

Telco A/S reserves the right to make changes without prior notice

tel

Product Data

Electrical Data

Supply Voltage

10 – 30 V dc

Voltage ripple

+/- 15%

Current consumption

30 mA

Max. output load

200 mA / 30 V dc

Reverse polarity protected

Yes

Short circuit protected

Yes

Environmental Data

Temperature, operation

-20 to +60 ºC

Sealing class

IP 67

Approvals

Available Models

Model

Supply

Voltage

Output

Output

Mode

Sensing

Range

Diffuse

Proximity

SMRR 7400 IO xx x 10-30 V

dc

IO-Link/NPN

Light/dark 0 – 3m*

SMRR 7500 IO xx x IO-Link/PNP

* Note: Measured against the Ø85 mm retro-reflector.

Illustration

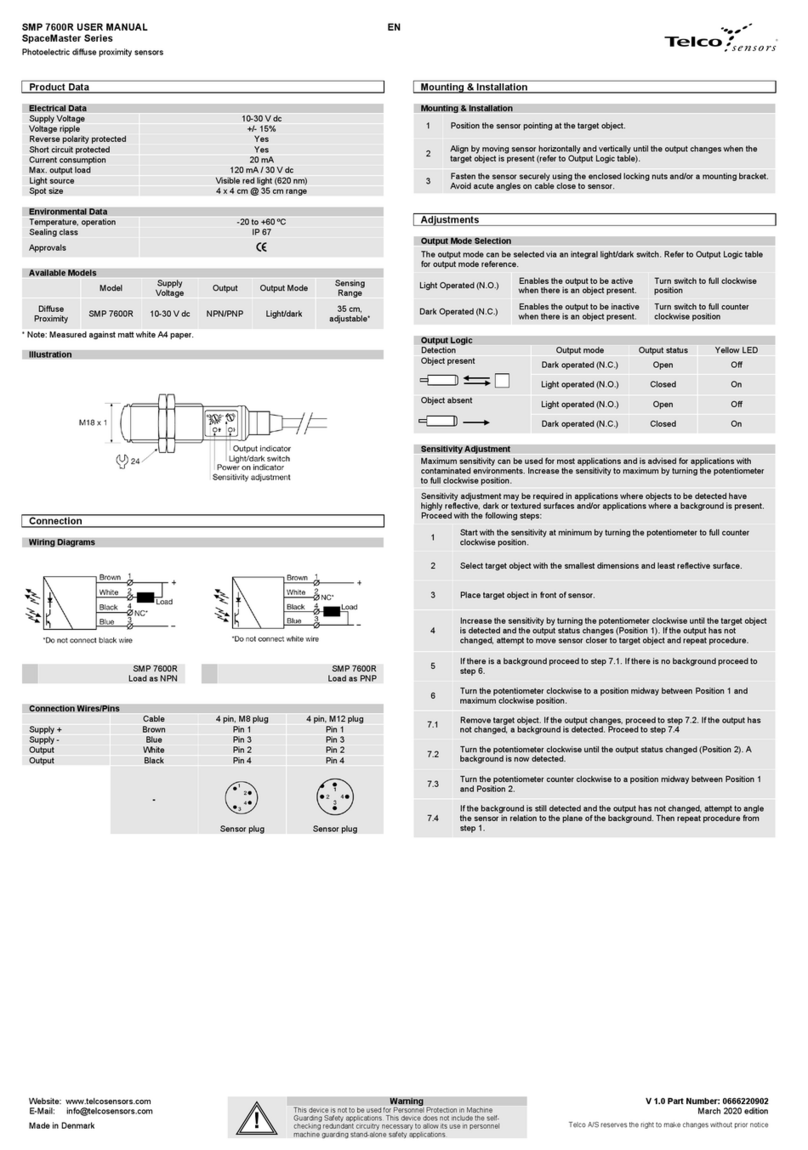

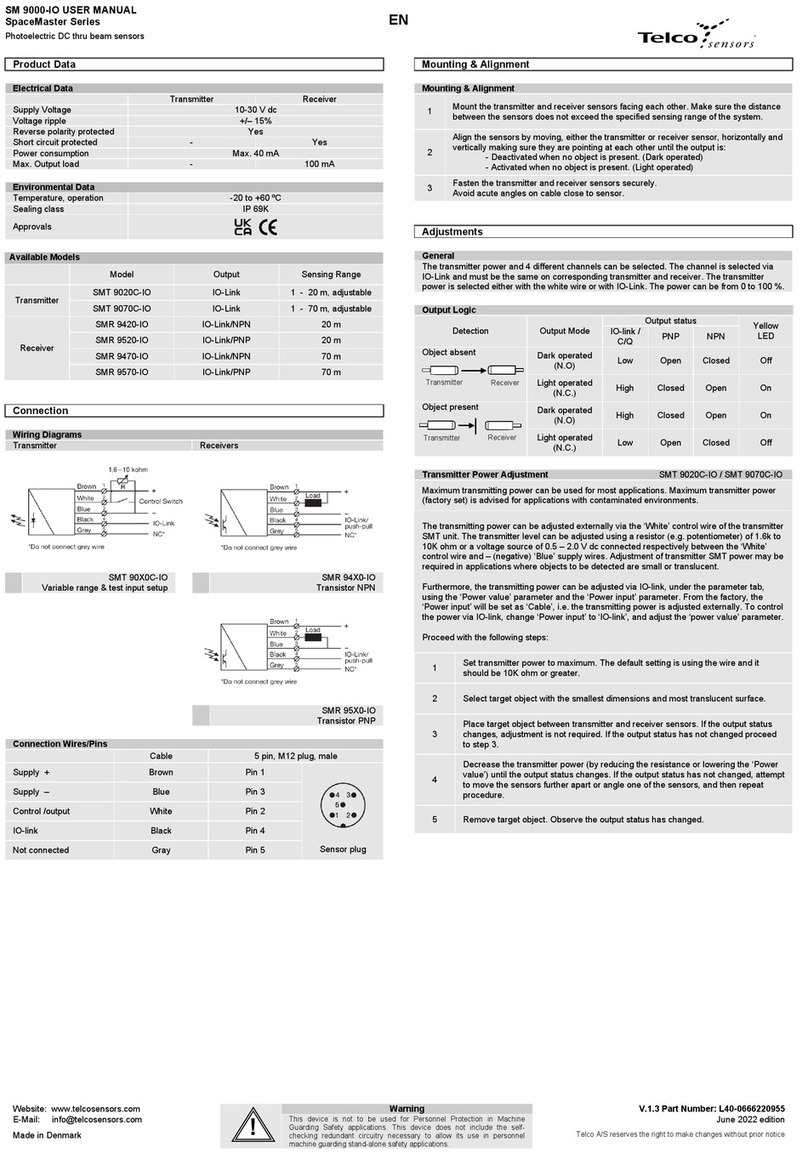

Connection

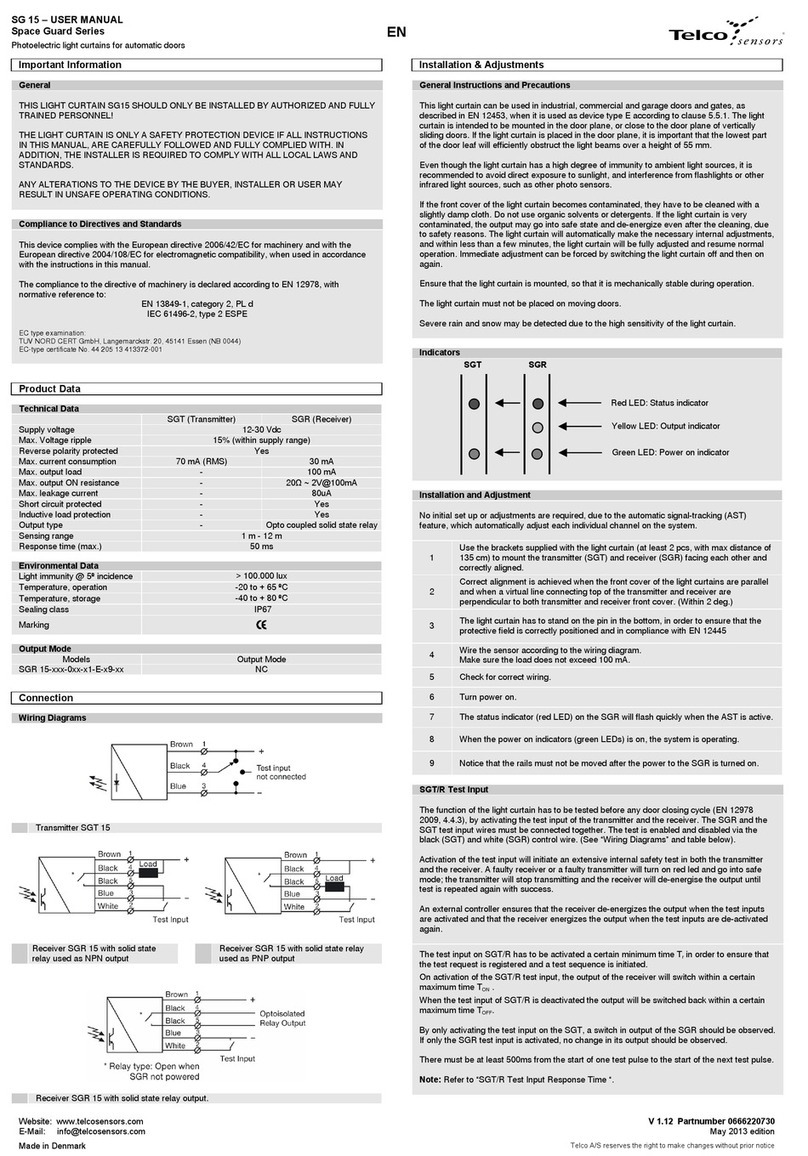

Wiring Diagrams

SMRR 7400 IO

Load as NPN

SMRR 7500 IO

Load as PNP

Connection Pins

4 pin, M8 plug

4 pin, M12 plug

Supply +

Brown

Pin 1

Pin 1

Supply -

Blue

Pin 3

Pin 3

IO-Link

Black

Pin 4

Pin 4

Control/Output

White

Pin 2

Pin 2

Sensor plug

Sensor plug

Mounting & Installation

Mounting & Installation

1 Position the sensor pointing at the target object.

2 Align by moving sensor horizontally and vertically until the output changes when the

target object is present (refer to Output Logic table).

3 Fasten the sensor securely using the enclosed locking nuts and/or a mounting bracket.

Avoid acute angles on cable close to sensor.

Adjustments

General

Sensitivity and output mode can be adjusted using the potentiometers or with the IO-Link.

The IO-Link allows the user to setup and read several functions and parameters. Please refer to

“SMRR and PC connection” on the following page.

Output Mode Selection

The output mode can be selected via an integral light/dark switch, or via IO-Link. Refer to Output

Logic table for output mode reference. Note that the NPN output is closed when IO-Link/push-

pull is low and the yellow output LED is off.

Light Operated (N.C.) Enables the output to be inactive

when there is an object present.

Turn switch to full clockwise

position, or set:

- Overwrite light operated = true

- Light operated = true

in the Parameters tab.

Dark Operated (N.O.) Enables the output to be active

when there is an object present.

Turn switch to full counter

clockwise position, or set:

- Overwrite light operated = true

- Light operated = false

in the Parameters tab.

Output Logic

Detection Output mode

Output status

Yellow LED

IO-Link

PNP

NPN

Object present

Light operated

(N.C.) Low Open Closed Off

Dark operated

(N.O.) High Closed Open On

Object absent

Light operated

(N.C.) High Closed Open On

Dark operated

(N.O.) Low Open Closed Off

Sensitivity Adjustment

Maximum sensitivity can be used for most applications and is advised for applications with

contaminated environments. The sensitivity can be adjusted on the potentiometer (factory

default active) or via IO-Link.

Sensitivity adjustment may be required in applications where objects to be detected have

highly reflective, dark or textured surfaces and/or applications where a background is present.

This can be achieved manually or via IO-Link.

For sensitivity adjustment, proceed with the following steps:

1 Start with the sensitivity at minimum by turning the potentiometer to full counter

clockwise position, or by setting the Gain value to 255.

2 Select target object with the smallest dimensions and most translucent surface.

3

Place target object between the sensor and retro-reflector. If the output status

changes, adjustment is not required. If the output has not changed proceed to step

4.

4

Decrease the sensitivity by turning the potentiometer counter clockwise or decrease

the Gain value to a lower value until the output changes.

If the output has not changed, attempt to move the sensor and retro-reflector further

apart or angle the sensor/retro-reflector. Then repeat procedure from step 1.

Alternatively, remove any object and press teach-gain button using IO-link.

5 Remove target object. Check the output status has changed.

!

SMRR 7000-IO - USER MANUAL EN

SpaceMaster Series

Photoelectric retro-reflective sensors with IO-link

Website: www.telcosensors.com

Warning

V 1.0 Part Number: L40-0666220939

E-Mail: info@telcosensors.com

This device is not to be used for Personnel Protection in Machine

Guarding Safety applications. This device does not include the self-

checking redundant circuitry necessary to allow its use in personnel

machine guarding stand-alone safety applications.

October 2021 edition

Made in Denmark

Telco A/S reserves the right to make changes without prior notice

tel

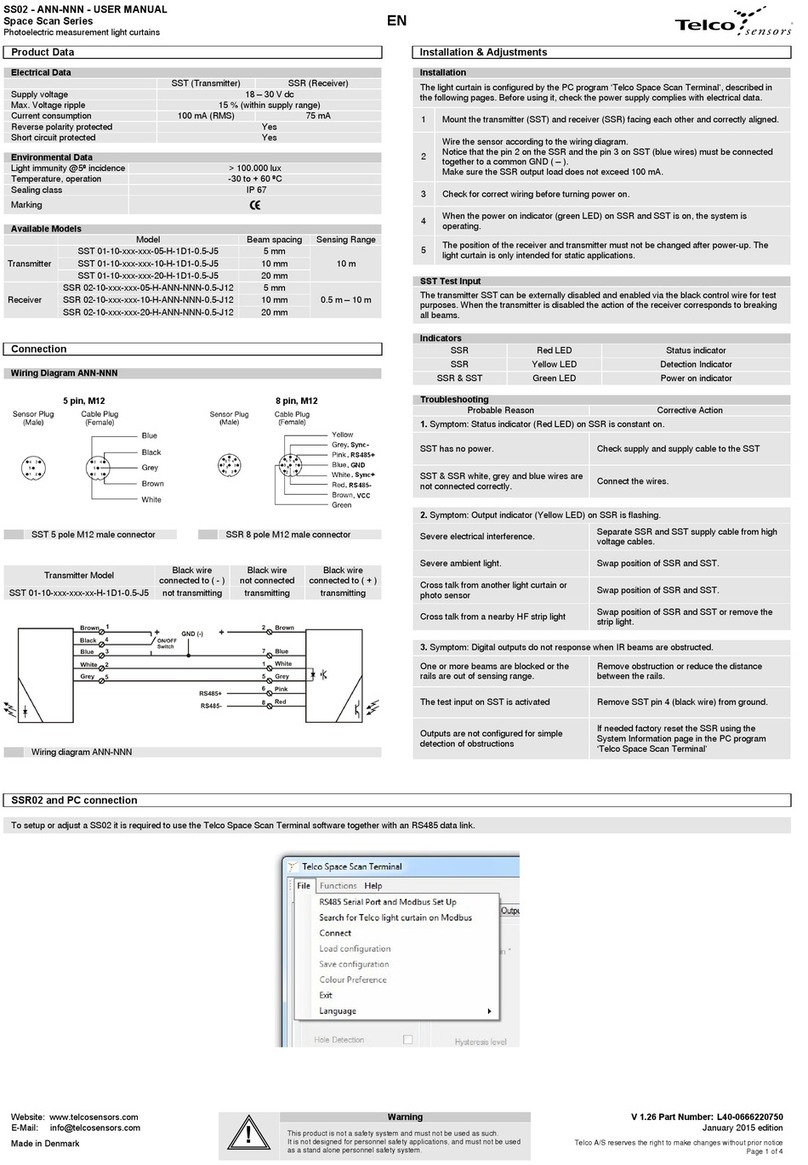

SMRR and PC connection

To setup or adjust a SMRR, it is required to use TMG IO-Link Device Tool together with TMG-USB IO-Link Master, or another IO-Link PC application.

How to connect

Connect the TMG-USB IO-Link Master USB-adapter to the USB-port of the PC and to the cable of the SMRR.

Download the IO-Link Device Tool software and the SMRR-IODD file from the Telco Sensors website in https://www.telcosensors.com/downloads selecting Software in Document type section.

Install the TMG IO-Link Device Tool V5.1.1-5122 SE – Setup file and run the program.

Import the SMRR-IODD by selecting “Import IODD” in the Options menu, previously downloaded.

Click on “Search Master” and select the Master in the popup window.

Click on “Go Online” .

Click on “Check Devices” .

Click on “Takeover devices into engineering” to the SMRR device.

Double click on the row with the SMRR, to open the Device menu.

Click on “Upload from Device”to upload the SMRR settings.

For more information see TMG’s User Manual for the IO-Link Device Tool.

Popup windows:

!

SMRR 7000 IO USER MANUAL EN

SpaceMaster Series

Photoelectric retro-reflective sensors with IO-link

Website: www.telcosensors.com

Warning

V 1.0 Part Number: L40-0666220939

E-Mail: info@telcosensors.com

This device is not to be used for Personnel Protection in Machine

Guarding Safety applications. This device does not include the self-

checking redundant circuitry necessary to allow its use in personnel

machine guarding stand-alone safety applications.

October 2021 edition

Made in Denmark

Telco A/S reserves the right to make changes without prior notice

tel

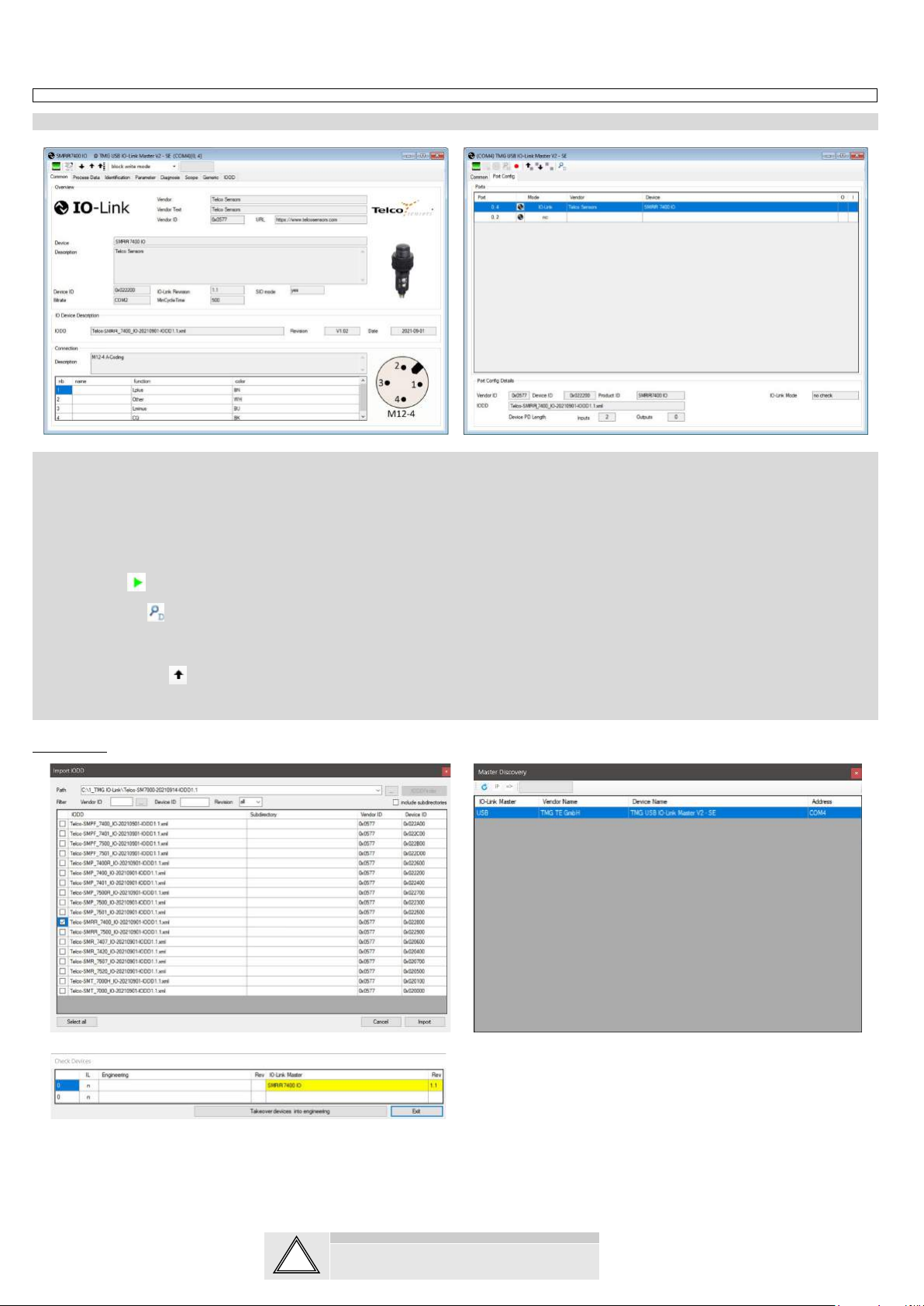

Parameters

On the Parameter tab, the parameters of the sensor can be set up or modified.

General settings SMRR:

System Command - Restore Factory Settings

Restores all user-settings to default values.

System Command – Teach Gain

Determines the lowest possible gain to turn on.

Hysteresis

The relative difference between on and off threshold. In both IO-Link and Potentiometer gain input it is possible to set the Hysteresis level. It can be set from 0 to 10%.

Gain input

Select how the gain should be controlled. Select between Potentiometer or IO-Link. IO-Link is set by the Gain value setting. Keep objects out of the detection area when switching to teach-in mode,

because the initial setting of the beam requires information about signal strength for an unbroken beam. Excess gain is adjusted to about 2.

Gain value

Select a fixed gain when IO-Link is selected for Gain input. It can be set from 0 to 255.

Light/Dark operated input.

How the light/dark operated should be determined. Select between Potentiometer or IO-Link.IO-Link is set by the “Light operated” value setting. Potentiometer is set by the potentiometer on the sensor.

Light operated

Select between true or false.

Changing the selection will invert the outputs, if the Overwrite light operated is true.

On delay

Select the delay of the output when an object appears, i.e. becomes present. It can be set from 0,00 to 600,00 seconds.

Off delay

Select delay of the output when an object disappears, i.e. becomes absent. It can be set from 0,00 to 600,00 seconds.

Oneshot time

Select how long time the outputs will be active when going from not active to active. It can be set from 0,00 to 600,00 seconds.

Forced output.

Select if the output should be forced to the value in Forced value or decided from the sensor input.

Forced value

Select the output state if the Forced output is true.

Operating Hours Event Time

Starts an event message when operating hours reaches the value. It can be set from 0 to 4294967295. If 0 is selected there will be no operating hours event.

!

SMRR 7000 IO USER MANUAL EN

SpaceMaster Series

Photoelectric retro-reflective sensors with IO-link

Website: www.telcosensors.com

Warning

V 1.0 Part Number: L40-0666220939

E-Mail: info@telcosensors.com

This device is not to be used for Personnel Protection in Machine

Guarding Safety applications. This device does not include the self-

checking redundant circuitry necessary to allow its use in personnel

machine guarding stand-alone safety applications.

October 2021 edition

Made in Denmark

Telco A/S reserves the right to make changes without prior notice

tel

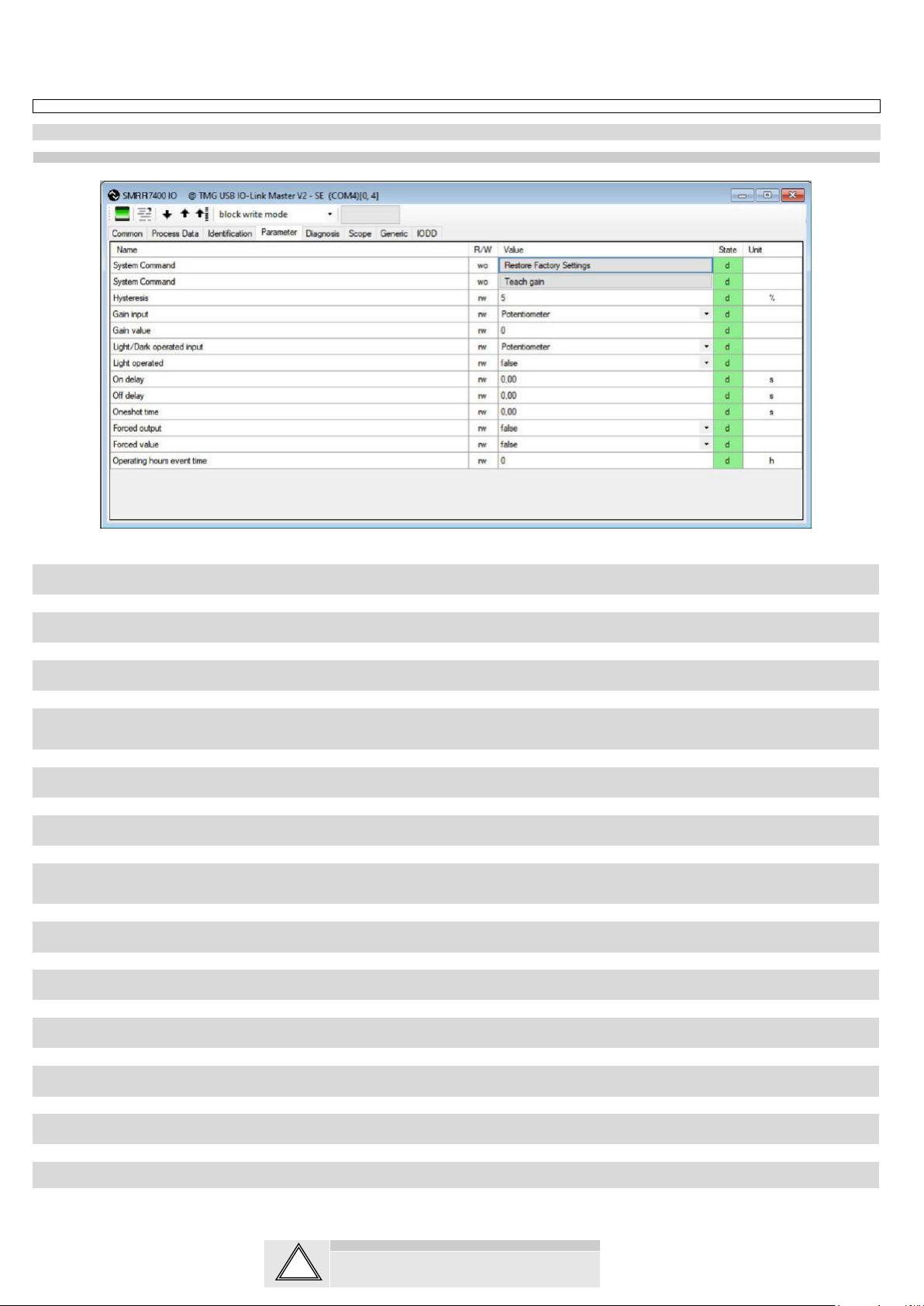

Process Data

Process data SMRR:

Output

Status on the output.

Light Operated

Status on the light operated selection.

Gain

Status on the gain value.

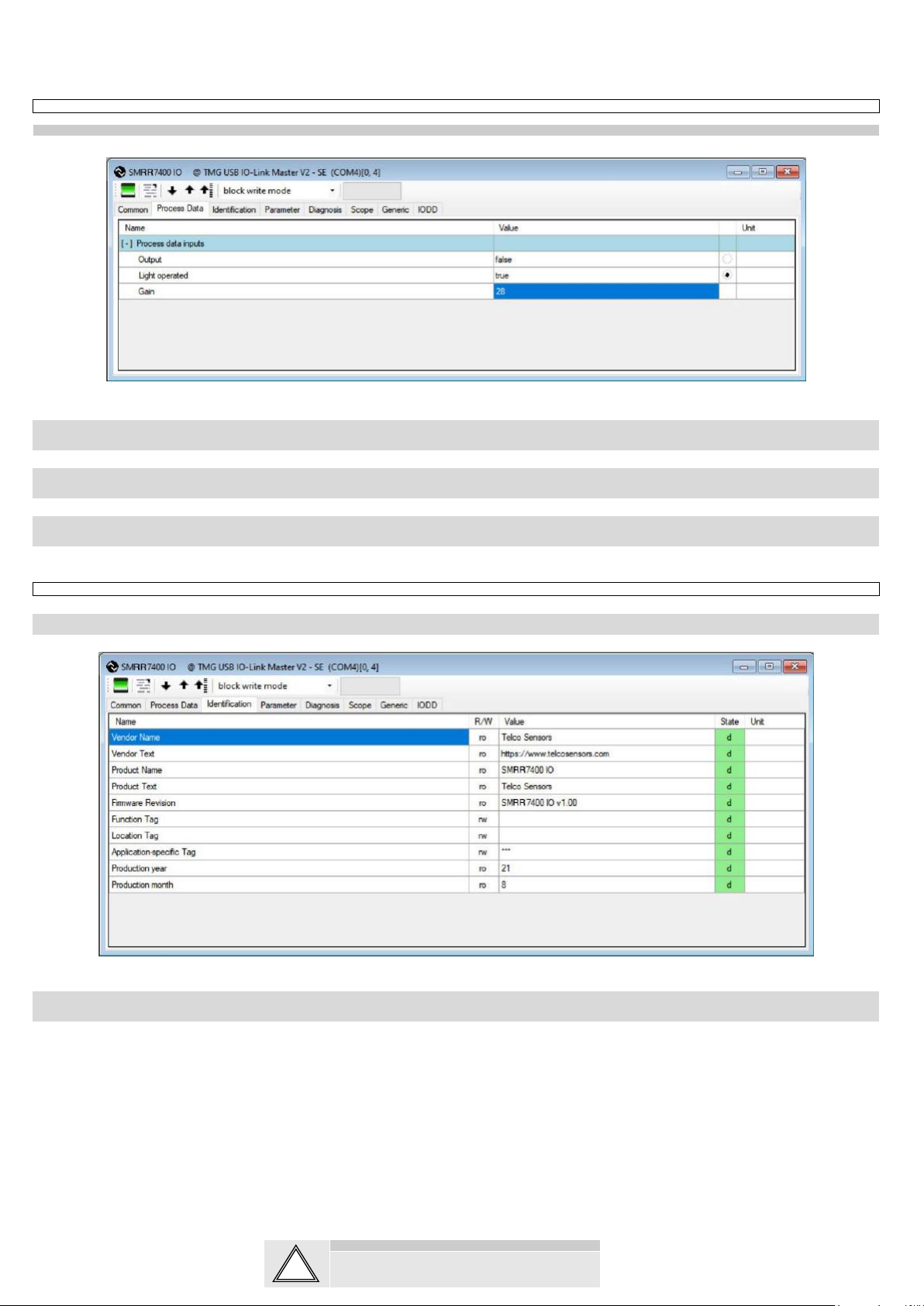

Identification

On the identification tab, general information about the sensor is displayed.

Function Tag, Location Tag and Application-specific Tag

Enter user specific descriptions for identification.

!

This manual suits for next models

1

Other Telco Sensors Accessories manuals

Telco Sensors

Telco Sensors SpaceMaster Series User manual

Telco Sensors

Telco Sensors SpaceMaster Series User manual

Telco Sensors

Telco Sensors Space Scan Series User manual

Telco Sensors

Telco Sensors Space Guard Series User manual

Telco Sensors

Telco Sensors SM 3000/CAT2 Series User manual

Telco Sensors

Telco Sensors SpaceMaster Series User manual