1

CONTENTS

INTRODUCTION ................................................................................................. 2

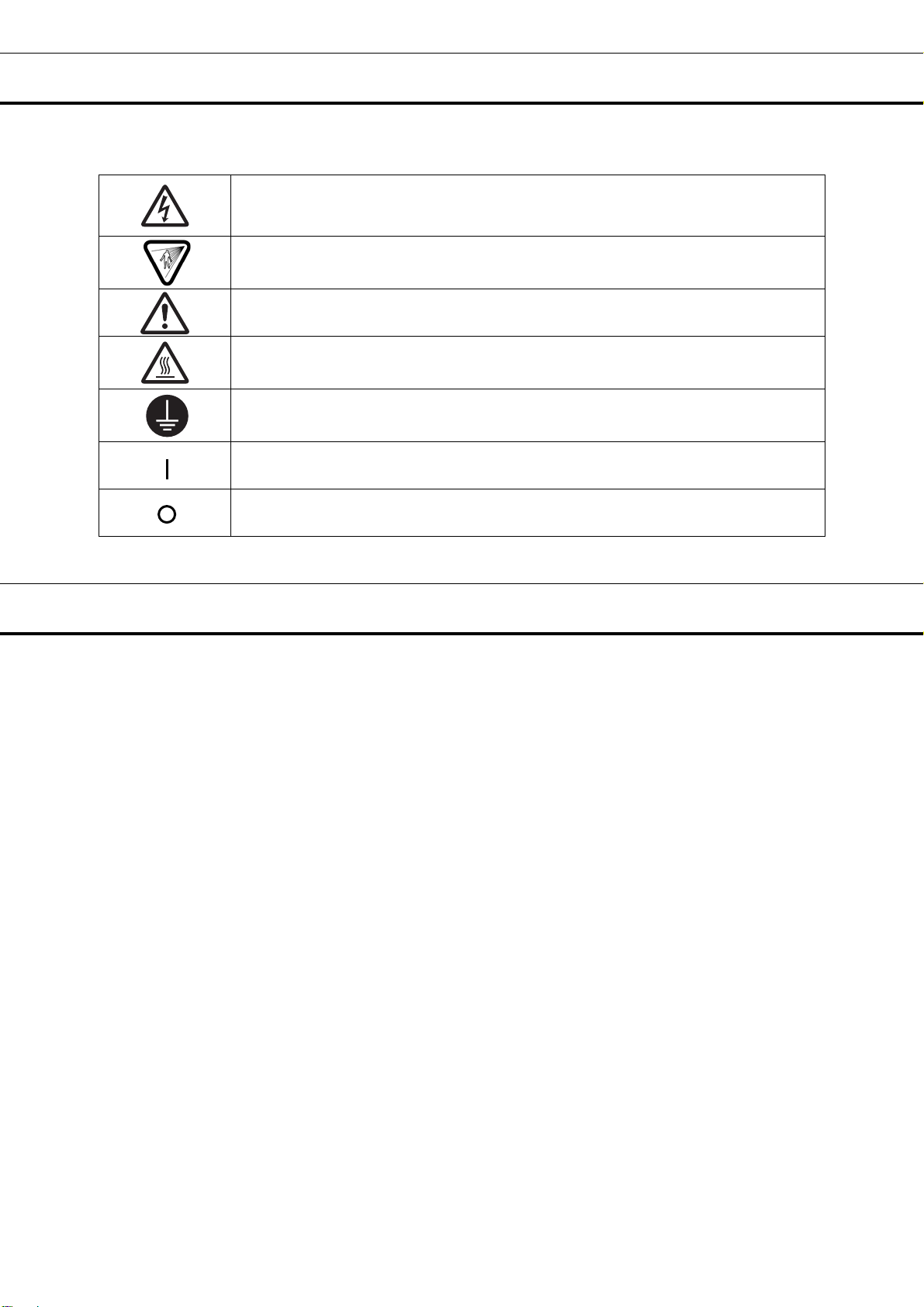

PRECAUTIONS FOR SAFE OPERATION.......................................................... 3

LABELS ON THE INCUBATOR .......................................................................... 8

ENVIRONMENTAL CONDITIONS ...................................................................... 8

INCUBATOR COMPONENTS ............................................................................ 9

Control panel and keypad .............................................................................. 11

Remote alarm terminals ................................................................................ 13

INSTALLATION SITE ........................................................................................ 14

INSTALLATION ................................................................................................. 15

Connecting a CO2gas cylinder ...................................................................... 16

Connecting a N2(or O2) gas cylinder ............................................................. 17

Connecting a gas injection nozzle.................................................................. 18

PREVENTING CONTAMINATION .................................................................... 19

PRECAUTIONS FOR CULTURES.................................................................... 20

INITIAL CLEANING METHOD ......................................................................... 21

REMOVING INNER ATTACHMENTS ............................................................... 22

INSTALLING INNER ATTACHMENTS.............................................................. 24

FILLING THE HUMIDIFYING PAN.................................................................... 25

WATER LEVEL SENSOR.................................................................................. 26

ROUTINE MAINTENANCE................................................................................ 27

CORRECT OPERATION................................................................................... 27

OPERATION OF KEYS ON THE CONTROL PANEL....................................... 28

SETTING OF ALARM RESUME TIME.............................................................. 29

Operation after power failure.......................................................................... 29

KEY LOCK FUNCTION ..................................................................................... 30

AUTOMATIC GAS CYLINDER CHANGEOVER ............................................... 31

UV LAMP ........................................................................................................... 33

Change of setting for UV lamp ON period...................................................... 34

Precautions when using the UV lamp ............................................................ 35

Lighting the UV lamp for 24 hours.................................................................. 36

ALARMS, SAFETY, AND SELF-DIAGNOSIS ................................................... 37

CALIBRATION

Temperature calibration ................................................................................. 39

O

2calibration.................................................................................................. 40

CO

2calibration ............................................................................................... 41

TROUBLESHOOTING....................................................................................... 42

DISPOSING OF THE O2/CO2INCUBATOR...................................................... 44

STACKING INCUBATORS................................................................................ 49

SPECIFICATIONS............................................................................................. 51

PERFORMANCE............................................................................................... 52

SAFETY CHECK SHEET .................................................................................. 53