www.phenomenex.com 4

A. Four Key Steps to Protecting the GC Column and

Extending Lifetime

It is important to protect the column and instrument components from exposure

to dirty samples. Non-volatile or high molecular weight components can

contaminate the stationary phase, causing peak resolution, lower accuracy, and

poor column lifetime. Cutting off the damaged portion will usually restore the

column performance, but over time performance will degrade to a point where

the column can no longer be used. If you are experiencing rapid degradation of

column performance, there are several simple ways to help protect your column

and increase lifetime:

1. Ensure Proper Sample Preparation

a.Filter your samples prior to injection with Phenex™syringe filters (see

Appendix A for details).

b.Use Strata®or Strata

™-X* SPE Cartridges to eliminate contaminants (see

Appendix D for details).

2. Use a Guardian™or Z-Guard

a.Guard Columns – Standard Guards. Z-Guard columns are 5 or 10 meter

pieces of deactivated tubing that are connected to an analytical column

using a glass press-fit connector. The tubing acts like a trap for non-

volatile residues that would otherwise damage the stationary phase of your

analytical column.

b.Guardian Integrated Guard Columns. Unlike traditional guard columns,

there is no mechanical connection between the guard and the analytical

column. The result: all the benefits of a guard column without the possibility

of leaks or activity resulting from a faulty connection. Please contact a

Phenomenex GC Specialist for information on the Guardian.

3. Use a Wool Liner

The liner is the first line of defense for the column and the style chosen can make

a big difference in how much contamination gets onto the column. The easiest

thing to do is to add a small amount of silanized glass wool to a liner, which

traps the non-volatile compounds and prevents them from entering the column

(Figure 3). See Appendix B for other recommended GC accessories.

Caution: glass wool can also add activity for acids, bases, and pesticides.

Crushing the glass wool can lead to increased activity, so it is recommended to

purchase pre-packed liners, rather than try to pack your own.

Figure 3. Some liners that are available pre-packed with glass wool or provide

additional column protection:

4. “Baking Out” the Column

The easiest way to reduce column contamination is to add a short, high

temperature bake out at the end of the standard GC method. This bake out helps

remove high boiling contaminants that would otherwise remain in the column

and cause damage. To bake out, the final oven temperature needs to be set

high enough to ensure elution of these compounds, but not so high as to cause

thermal damage. This can be done either isothermally, or more commonly, via a

gradient or ballistic increase until the last components elute from the column.

Caution: NEVER exceed the upper temperature limits of the column. DO NOT

exceed more than 15 minutes at the upper isothermal temperature limit specified

for the column.

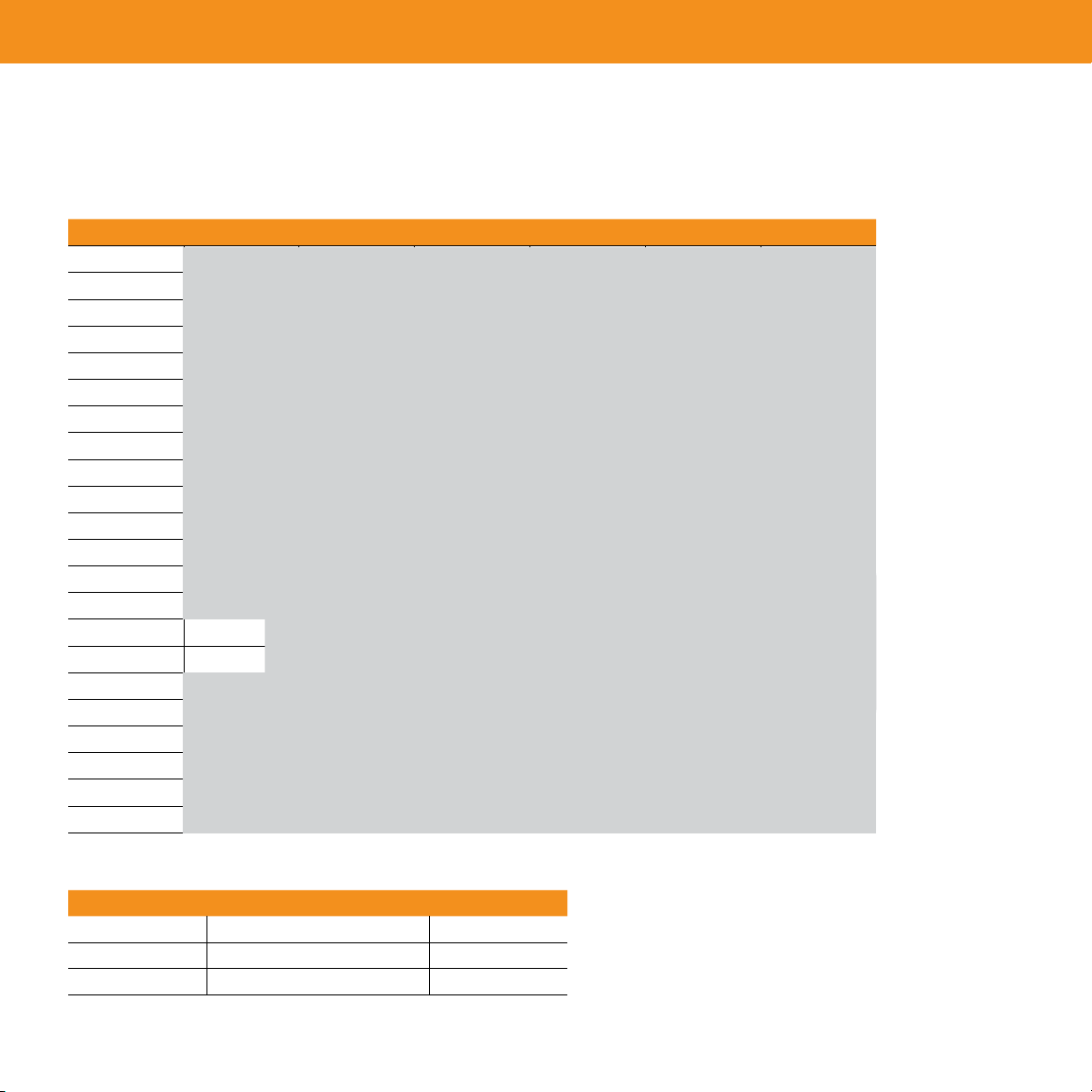

Description

GC Model No.

Dimensions

ID x L x OD

(mm)

Material*

(deactivated)

Quartz Wool

(Y / N) Mfr. No. Part No. Unit

Split/Splitless

5880/5890/6890 4 x 78.5 x 6.3 B (y) Y 210-4004 AG0-7515 5/pk

AG0-7582 25/pk

Split/Splitless, Recessed Gooseneck Liner

5880/5890/6890 4 x 78.5 x 6.45 B (y) Y 5183-4691

5183-4692

AG0-4661

AG0-4662

5/pk

25/pk

Cup Splitter/Split Liner

5880/5890/6890 4 x 78.5 x 6.3 B (n) N 5183-4699 AG0-4647 5/pk

5183-4700 AG0-4648 25/pk

Cup Splitter/Split Liner

AutoSystem™3.5 x 100 x 5 B (n) N 0330-5181 AG0-4663 5/pk

Splitless Single Taper/Liner

5880/5890/6890 4 x 78.5 x 6.45 B (y) Y 5183-4693

5183-4694

AG0-4657

AG0-4658

5/pk

25/pk

* B = Borosilicate; Deactivated = Yes (y) or No (n)

GC Hints and Tips

*Strata-X is patented by Phenomenex, Inc.