General - Please read the following precautions carefully before installing and connecting the

system to a power source.

Note –Only qualified and trained service personnel (in accordance with IEC 60950 and AS/NZS

3260) should install, replace, or service the equipment. Install the system in accordance with

Country, National or to the U.S. National Electric Code if you are in the United States.

Precautions:

1. The building facilities in which the product will be used must provide Isolation to the main

AC Input connector. This connection requires a fuse or circuit breaker no larger than 20A for

120 VAC (U.S.A.) or 16A, 230 VAC (international). The building facilities must protect the

POE62U Power injector from over current or short-circuits.

2. The POE62U power injector enclosure is IP67 tested which provides degrees of protection

against access to hazardous parts, dust and against ingress of water. To ensure protection

against ingress of water, torque captive screws (4 places) in an “X” pattern to > 27 inch

pound. –Only qualified service personal should install, replace or service this equipment.

Before connecting, visit “www.phihong.com” for the latest up to date specification and

contact information.

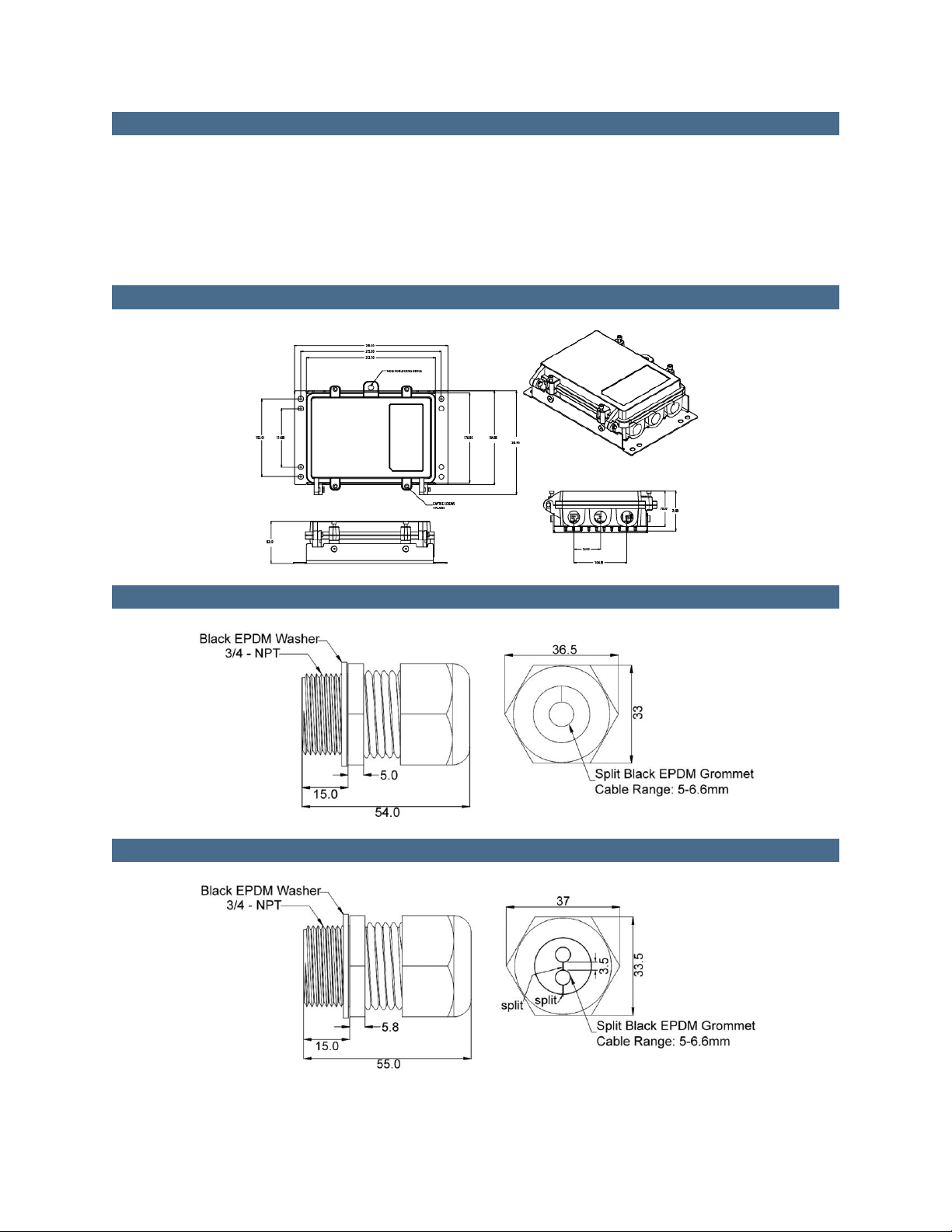

3. The POE62U power injector enclosure must be mounted vertically but not orientation

limited. The enclosure is provided with a steel 2mm thick zinc plated mounting bracket.

When mounting utilize the holes in the mounting bracket plate (10mm holes) 8 places. The

preferred method of mounting is to a vertical 4 inch or 6 inch pole using 2”3/8 x 16” U-

bolts. If mounting on a flat surface, to sheetrock or wood and or others material, use 4 M6

fasteners. Other fasteners may be used, but hardware must be sized to support 4-5 times the

weight of the unit.

4. The POE62U power injector enclosure has 3 threaded (¾ NPT) openings to accommodate

waterproof / water tight conduit and or cable glands. WARNING: To ensure protection

against ingress of water, the connection(s) of the conduit and or cable glands are threaded

with Teflon tape all the way through the holes in an enclosure wall.

5. The POE62U power injector AC input connector (located inside enclosure) is a 3 pin terminal

block 9.5mm, rated 20 A, 250 V, with M3.5 Nickel Plated steel screws. The incoming 3

wire/cable must be minimum 14AWG and or in accordance with Country, National Electric

Code.

6. The POE62U Power injector consists of “Data & Power” ports. The ports are providing

TNV-1 outputs. The ports use RJ-45 data sockets. Do not connect telephone cables into

these ports. Only RJ-45 data cables with waterproof / water tight connections may be

connected to these sockets.

7. To prevent the POE62U Power injector from overheating, do not operate the product in an

area that exceeds the maximum recommended ambient temperature of -40 ºC to +60 ºC.