QP-10-IM21UL/Rev 12

•

Please use PV modules with same cell size within series.

•

Follow all safety precautions of other components used in the system.

•

In order to avoid a risk of injury or electrical shock, do not allow anyone to approach the

PV module if the person has little knowledge on PV module or on the measures that should

be taken when PV modules are damaged.

•

Do not shade portions of the PV modules surface from the sunlight for a long time. The

shaded cell may become hot (hot spot phenomenon) which results in solder joints peeling

off.

•

Do not clean the glass surface with chemicals. Do not let water stay on the glass surface

of PV modules for a long time. This creates a risk of white efflorescence (glass disease)

which may result in the deterioration of energy generation.

•

Purity degree of washing water shall be considered to avoid any chemical reaction with

PV Modules glass cover.

•

Do not install the PV module horizontally. it may cause

dirt or white efflorescence (glass

disease) due to water

•

Do not cover the water drain holes of the frame. There is a risk of frost damage when the

frame is filled with water accumulation.

•

When sliding snow load has to be considered, an appropriate measure has to be taken

so that PV module frames on lower edge of PV modules will not be damaged.

•

Do not expose PV module to concentrated sunlight with mirrors, lenses or similar means.

•

Turn off inverters and circuit breakers immediately, if any problem occurred.

•

In case the glass surface of a PV module is broken, wear goggles, gloves and tape the

glass to keep the broken pieces in place.

•

A defective PV module may generate power even if it is removed from the system. It may

be dangerous to handle the PV while exposed to sunlight. Place a defective PV module

in a carton so PV cells are completely shaded.

•

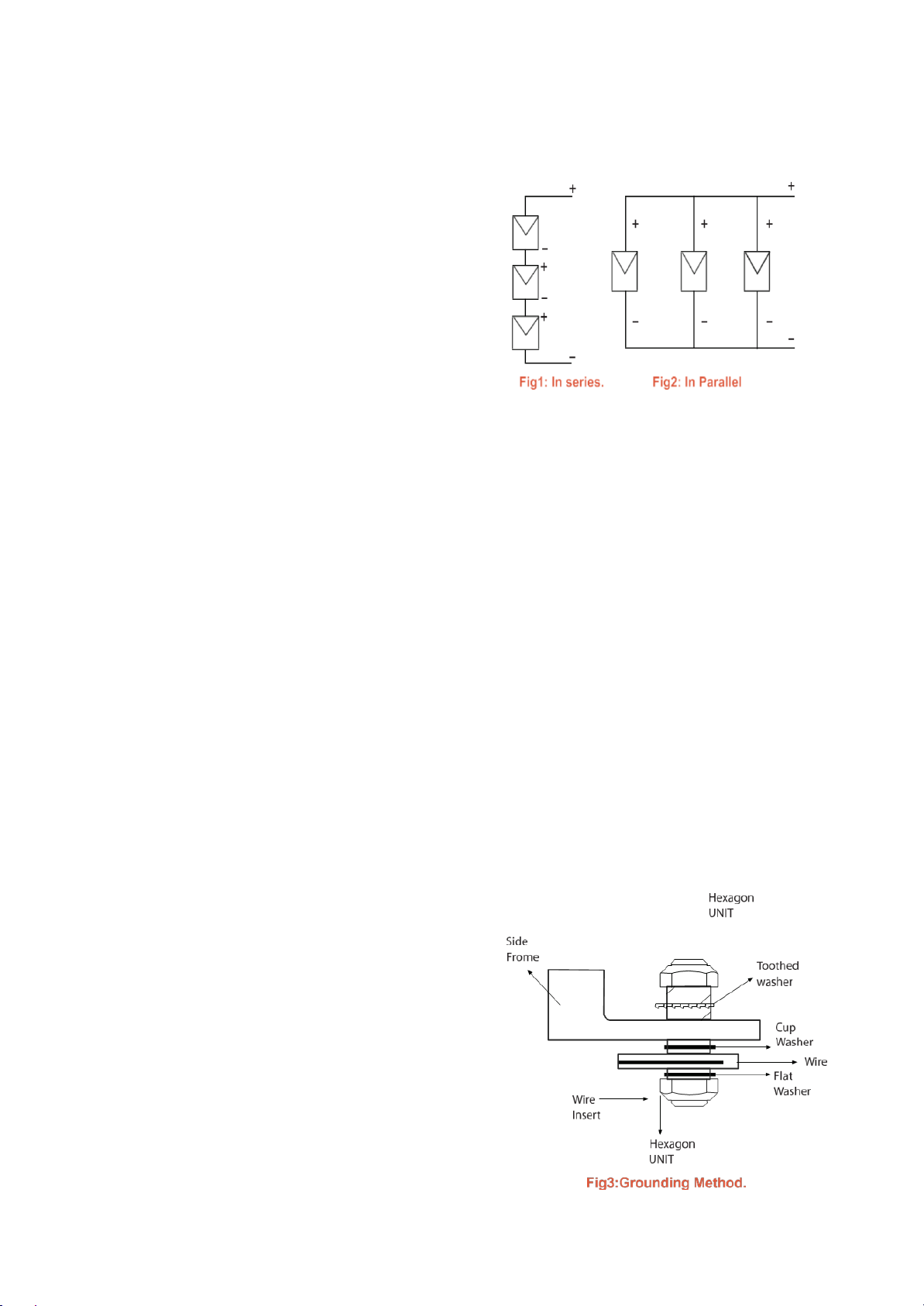

In case of series connection, Number of Series Modules shall be determined according to

the minimum design temperature for installation location and not to exceed

1000Vdc/1500Vdc for the string of series PV Modules at any time. The maximum open

circuit voltage must not be greater than the specified maximum system voltage as per

below equation:

•

In case of series connection, Number of Series

•

Max System Voltage ≥ N * Voc * [1 + TCvoc x (Tmin-25)].

•

Where N refers to number of modules, TCvoc: Thermal Coefficient of open circuit voltage