NEW ROYAL 01 INTRODUCTION

Saeco International Group Rev. 00 / July 2011 Page / 04

1.1. Documentation required

The following documentation is needed for repair procedures:

• Instructionbookletforspecicmodel.

• Technicaldocumentationforspecicmodel(diagrams,explodedviews).

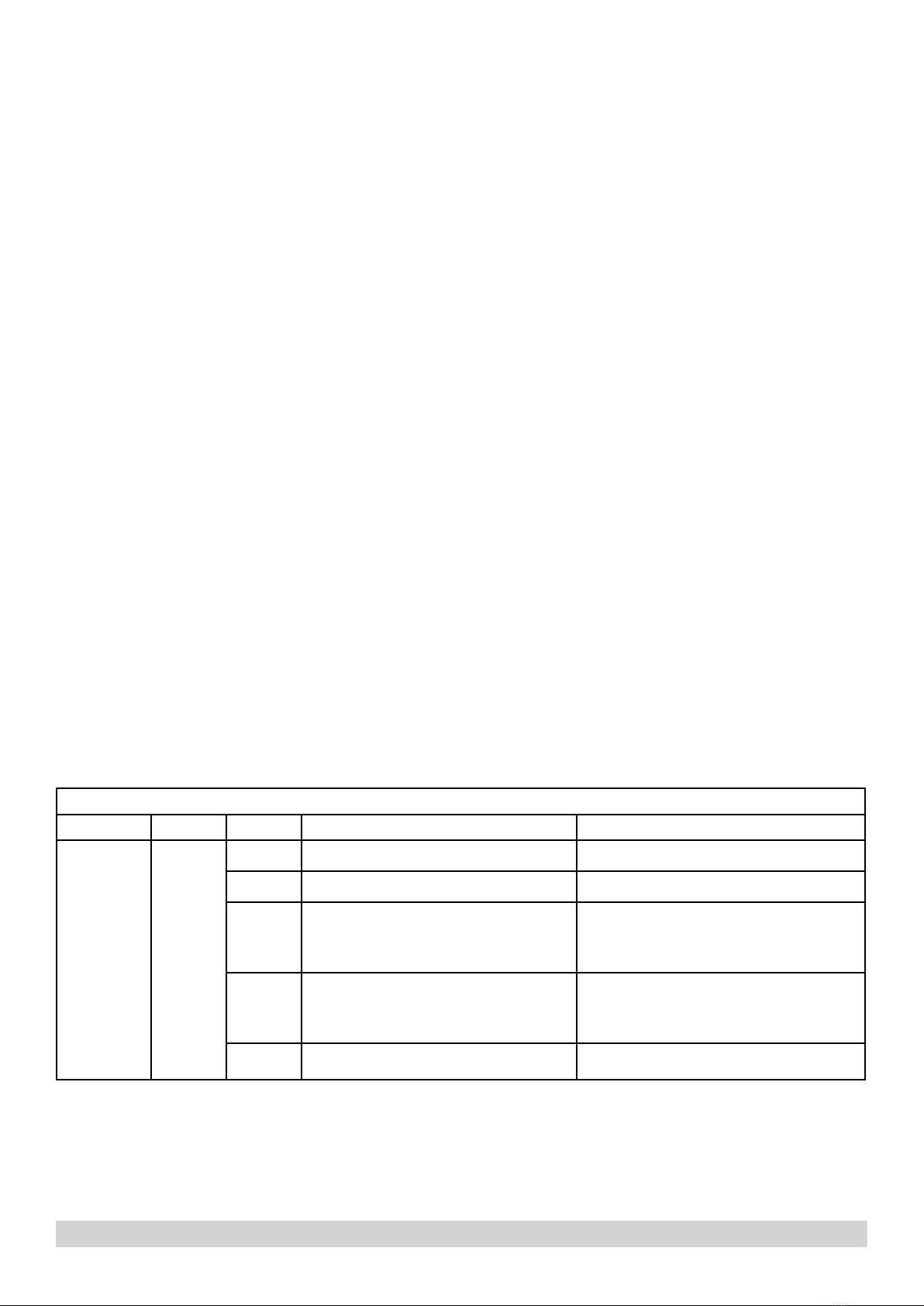

1.2. Tools and equipment required

Aswellasthestandardequipment,thefollowingisrequired:

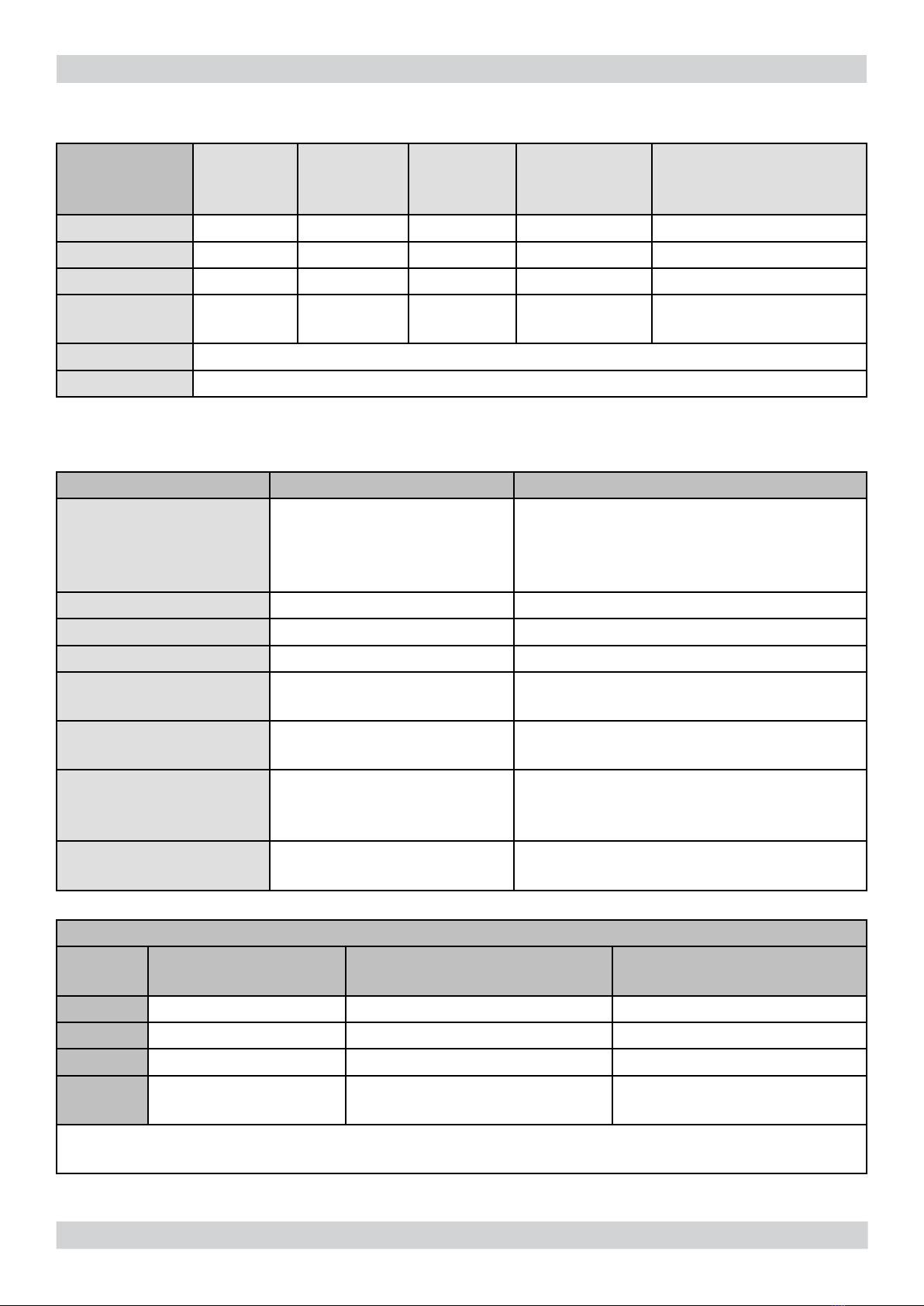

Qty. Description Notes

1 Screwdriver TorxT8-T10-T20

1 Screwdriver Cross-head

1 Pliers for Oetiker clamps

1CC-A-Vdctester

1 Digital thermometer Scale limit > 150°C

1SSC(SaecoServiceCenter) Programmer

(forprogramminganddiagnosticsmode)

1.3. Material

Description Notes

Thermal paste Heating element > 200°C

Descaler Saeco descaler

Grease solvent Personal choice

Silicone grease Safe to use with food

1.4. Safety warnings

We recommend you consult the technical manual of the machine before performing any mainte-

nance work.

Observe all applicable standards relating to the repair of electrical appliances.

Always disconnect the power plug from the mains before beginning repair work.

01

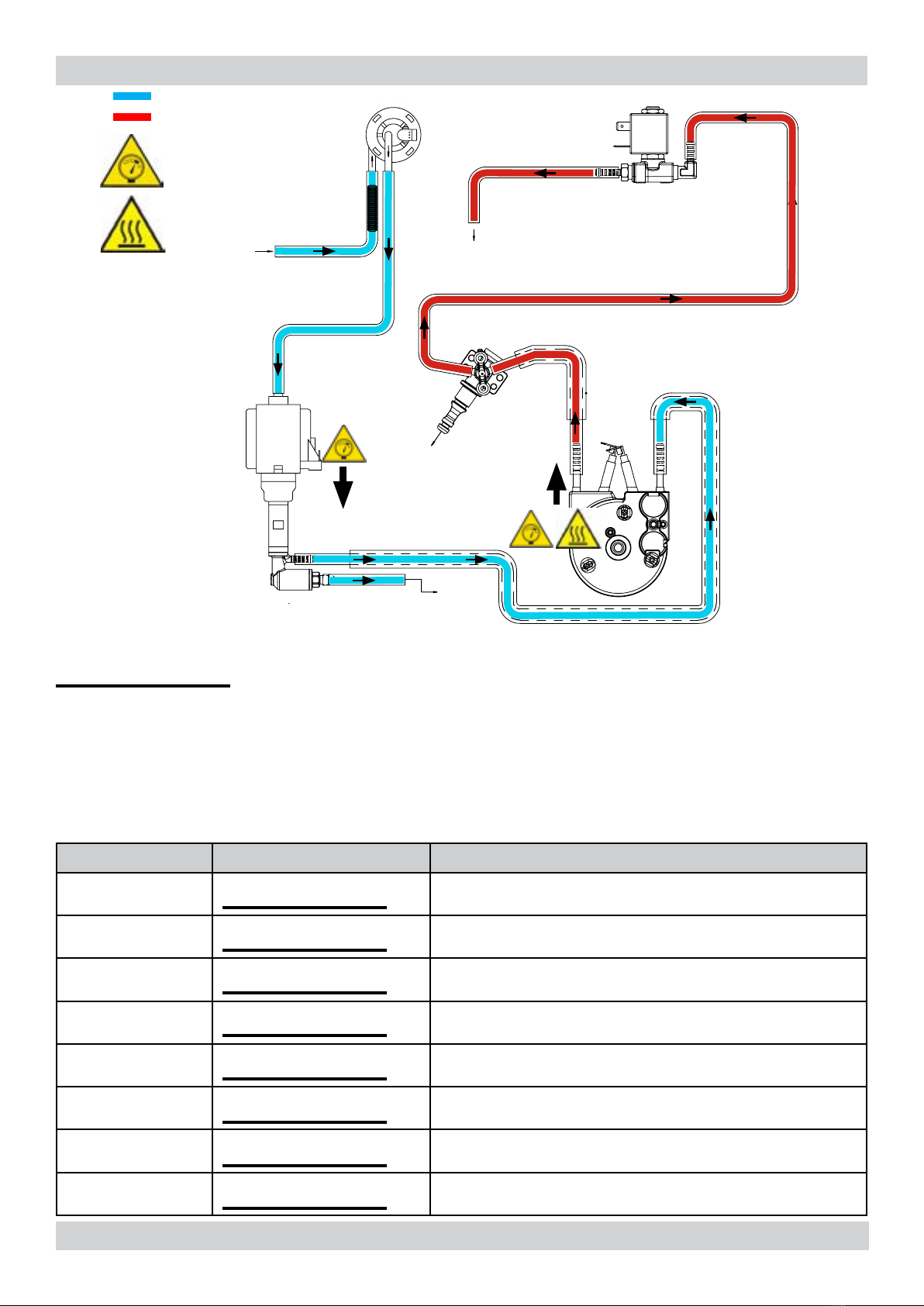

Disassemblingthemachine,theoperatormustpayattentiontohotandunder

Pressureparts:boiler,pin-boiler,valves,dispensing,steamtube,brewunit,

connectionsandpipestoavoidburns.Pleaserefertospecichydrauliccircuit

(Image1)toknowthepartsindetail.

Themachinehydrauliccircuitcanreachmaximumpressureof16/18bar.

To operate in safety condition is recommended to perform the Steam Out procedure in

order to remove the pressure and hot water inside the hydraulic circuit.

Simply turning off the main machine power switch is not an adequate safety

precaution.

This domestic appliance is rated as insulation class I.

Oncompletionoftherepairwork,insulationanddielectricrigiditytestsmustbe

performed.