07

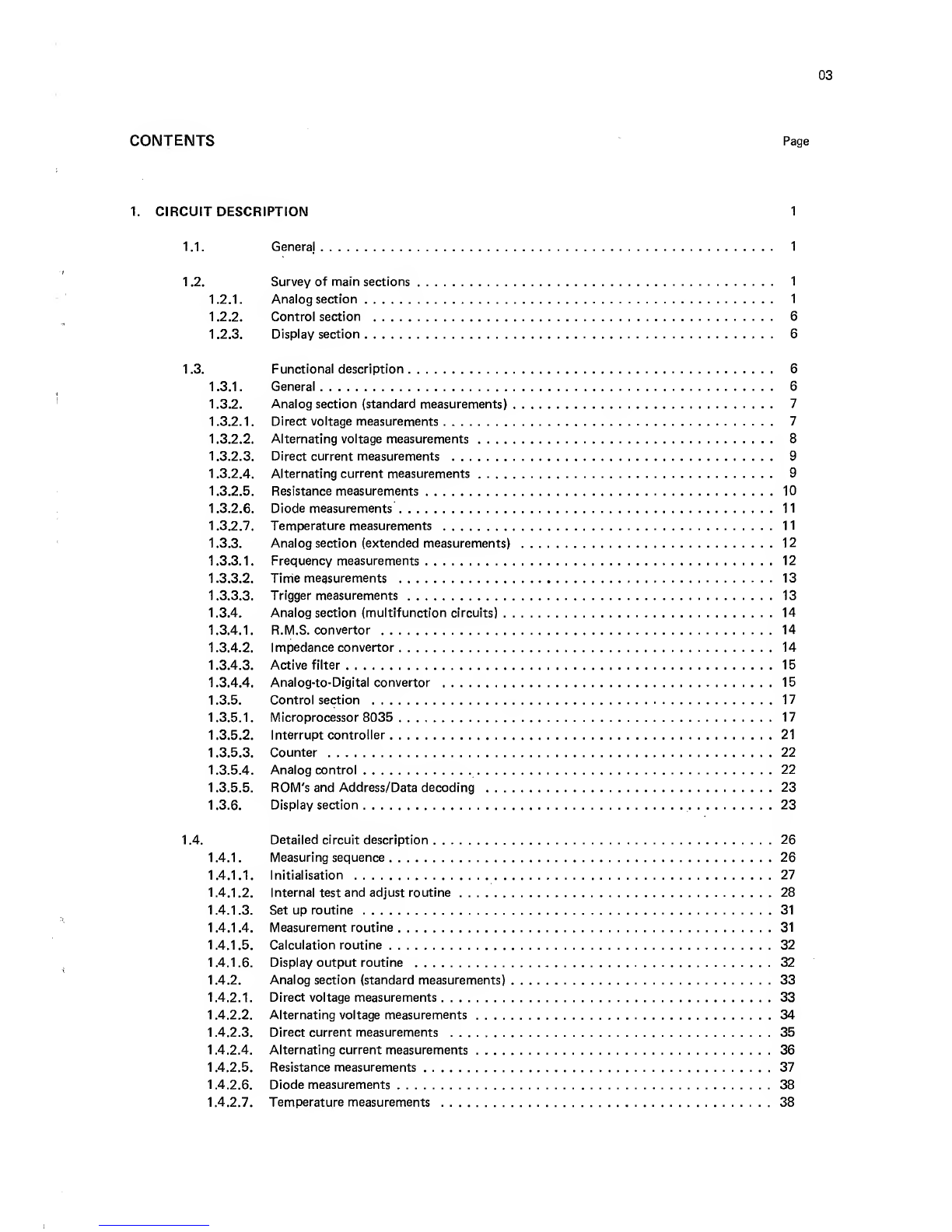

LIST OF FIGURES

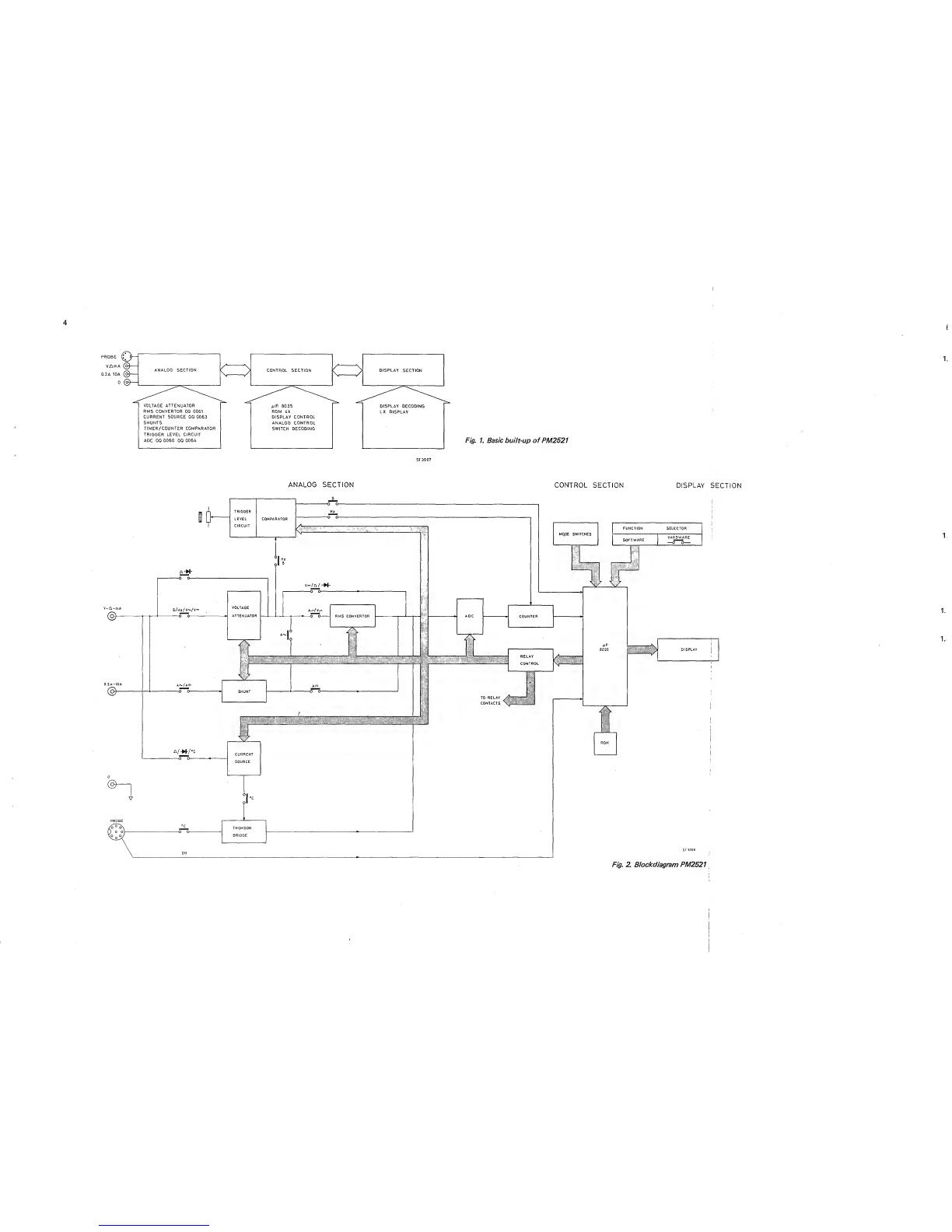

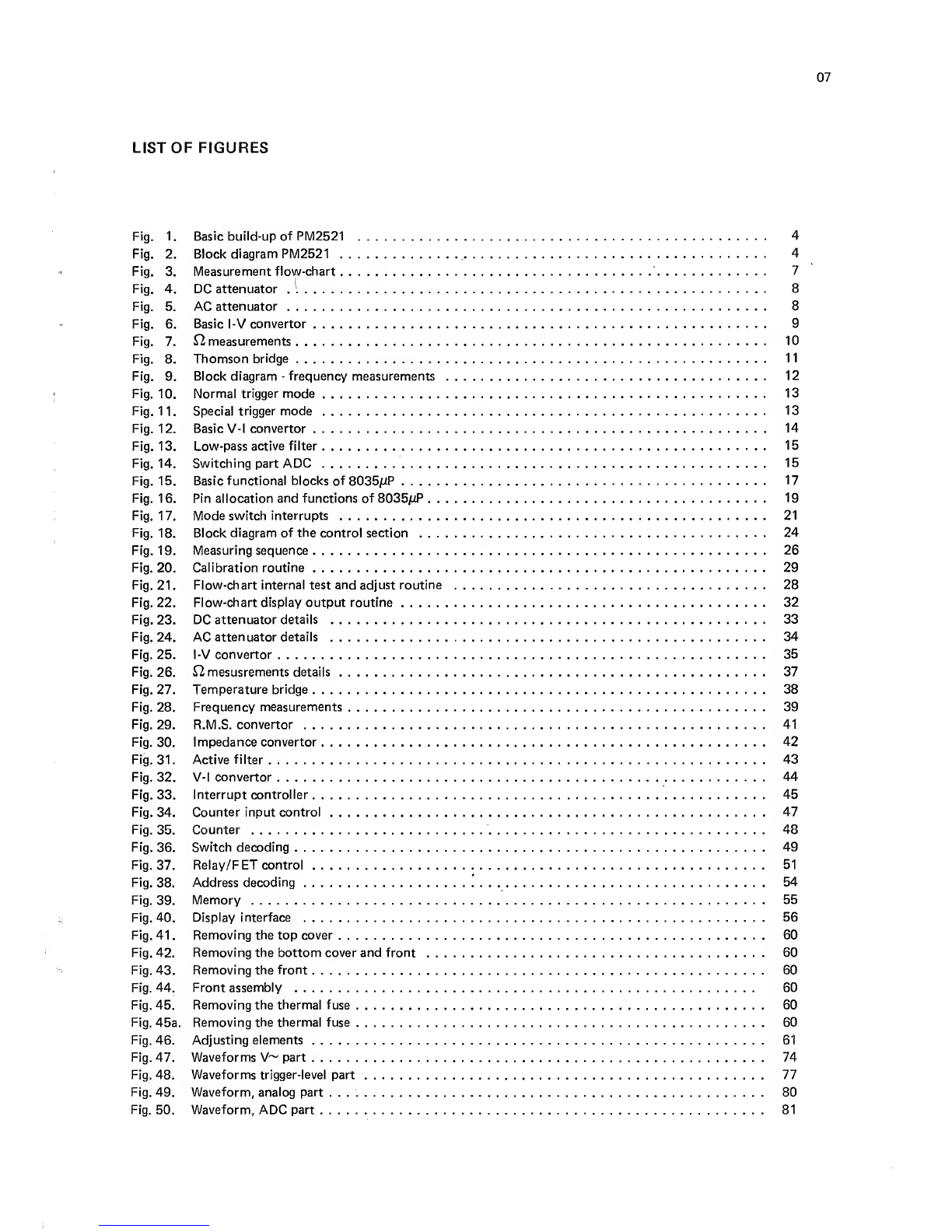

Fig. 1. Basic build-up of PM2521 4

Fig. 2. Block diagram PIVI2521 4

Fig. 3. Measurement flow-chart ... 7

Fig. 4. DC attenuator .1 8

Fig. 5. AC attenuator 8

Fig. 6. Basic 1-V convertor 9

Fig. 7. measurements 10

Fig. 8. Thomson bridge 11

Fig. 9. Block diagram -frequency measurements 12

Fig. 10. Normal trigger mode 13

Fig. 11. Special trigger mode 13

Fig. 12. Basic V-l convertor 14

Fig. 13. Low-pass active filter 15

Fig. 14. Switching part ADC 15

Fig. 15. Basic functional blocks of 8035/mP 17

Fig. 16. Pin allocation and functions of 8035/xP 19

Fig. 17. Mode switch interrupts 21

Fig. 18. Block diagram of the control section 24

Fig. 19. Measuring sequence 26

Fig. 20. Calibration routine 29

Fig. 21. Flow-chart internal test and adjust routine 28

Fig. 22. Flow-chart display output routine 32

Fig. 23. DC attenuator details 33

Fig. 24. AC attenuator details 34

Fig. 25. I-V convertor 35

Fig. 26. mesusrements details 37

Fig. 27. Temperature bridge 38

Fig. 28. Frequency measurements 39

Fig. 29. R.M.S. convertor 41

Fig. 30. Impedance convertor 42

Fig. 31. Active filter 43

Fig. 32. V-l convertor 44

Fig. 33. Interrupt controller 45

Fig. 34. Counter input control 47

Fig. 35. Counter 48

Fig. 36. Switch decoding 49

Fig. 37. Relay/FET control 51

Fig. 38. Address decoding 54

Fig. 39. Memory 55

Fig. 40. Display interface 56

Fig. 41 .Removing the top cover 60

Fig. 42. Removing the bottom cover and front 60

Fig. 43. Removing the front 60

Fig. 44. Front assembly 60

Fig. 45. Removing the thermal fuse 60

Fig. 45a. Removing the thermal fuse 60

Fig. 46. Adjusting elements 61

Fig. 47. Waveforms V~ part 74

Fig. 48. Waveforms trigger-level part 77

Fig. 49. Waveform, analog part 80

Fig. 50. Waveform, ADC part 81