PHOENIX CONTACT PHOENIX CONTACT

General

The 4-arbor crimping pliers are for crimping the machined crimp contacts in the list below.The pliers may only be

used if they are in technically perfect working order and are only to be used for the purpose described in the operating

instructions. With this crimping tool, the user is able to check the pliers at intervals he denes himself, and can calibrate

them, if necessary. To increase the process reliability for the user, the pliers have wear monitoring.This lets the user

know when the tool wear has exceeded a dened range.

The settings of the crimping pliers have been calculated based on the

withdrawal forces stated in DIN EN 60352-2 and by using a reference

conductor. Depending on the conductor used, the required

settings of the crimping pliers can dier from the values stated.

Procedure

• Switching on/o: The device is switched on/o by pressing the

"ON/OFF" button.

• Mode function: The "MODE" button is used to select the display

functions in mm or in inches, or the selector positions from 1-8 in

acc. with MIL 22520. Use the enclosed gauge to press the "MODE"

button as often as necessary to select the desired display:

Setting the crimping parameters / crimping operation

• Please refer to the enclosed setting matrix for the crimp arbor and

locator settings for the contact to be crimped.

• Loosen the clamping screw (condition when delivered).

• The crimping dimensions (crimping depth of the crimp arbors) are

set by turning the adjustment knob until the digital display shows the

required value. Please note that a larger crimping dimension must

always be selected than that to be set, e.g. select 1.2 mm and adjust

down to crimping dimension 1.0 mm.

• Depth settings clockwise reduce the crimping dimensions, while

counter-clockwise increases the crimping dimensions.

• Lock the crimping dimension setting using the clamping screw.

• Lift the locator at the side and turn to set it to the position dened in

the setting matrix. Insert the crimp contact as far as it will go into the

recess provided. The locator moves the crimp contact to the exact

position.

• Insert the prepared cable as far as it will go into the crimp contact in

the pliers and close the pliers tightly until the trigger block is unlocked.

Open the pliers and remove the crimped contact.

Do not crimp on the gauge or other similar objects to avoid

damage to the pliers. Avoid crimping solid materials (e.g. steel)

having a hardness greater than 35 HRC.

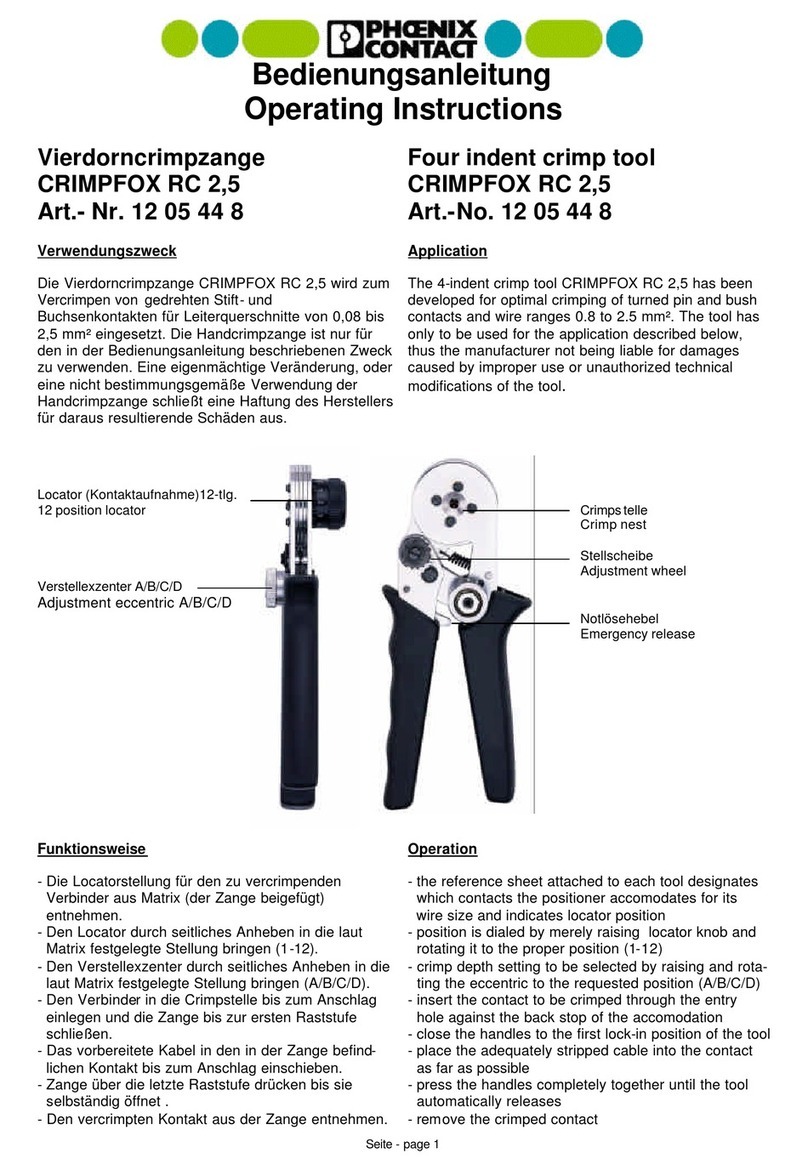

Crimping

recess

Digital display

Battery holder,

Battery type

CR2025 3 VOLT

"MODE" button

"ON/OFF" button

Adjustment knob for

accuracies of feed

depth of 0.01 mm

End stop

Locator, 12-section

Clamping screw for

locking the crimping

dimensions

Operating Instructions SF-Z0054

(Order No. 1615585)

4-arbor crimping pliers for

machined contacts with digital

display and wear monitoring

Standard display

in mm

Display in

inches

Display of comparable selector

positions in acc. with MIL

Changing the battery

The service life of the battery for the digital display is approximately one year, depending on how often it is used. To

change the battery (type CR2025, 3 VOLT), the battery holder is pulled out so that the battery can be removed and

exchanged. Before inserting the battery, make sure you set the pliers to the stop at the lower setting point.

How to further proceed is described in the section "Calibrating the reference value". Dispose of used batteries at

approved recycling centers.

Calibrating the pliers

The crimping pliers may only be calibrated by authorized skilled

personnel, since improper calibration can lead to incorrect

crimping.

• Adjust the crimp arbors to a setting dimension of 1 mm: Using the

adjustment knob, set the crimp arbors so that the enclosed gauge

can move between the crimp arbors without play. Please note that a

larger gauge dimension must always be selected than that to be set,

e.g. select 1.2 mm and adjust down to gauge dimension 1.0 mm.

• Keep the "ON/OFF" button pressed and press the "MODE" button

using the gauge. Keep the "MODE" pressed for at least 5 seconds.

Release the "MODE" button after 5 seconds and then the "ON/OFF"

button.

• The digital display automatically jumps to the gauge value 1.0 mm.

The pliers are adjusted and ready for the crimping parameters to be

set.

Wear monitoring

Every tool is subject to wear, even when used as intended.This wear is tolerable within certain limits and is

compensated during each calibration. Press the "Mode" button for 10 seconds (range: 8 to 15 s) to call up the current

tool status and to display the numerical output on the pliers. The following values are output consecutively:

• Serial number – current wear value – position value of the lower stop of the unworn pliers (xed value, specic to

pliers) – number of previous calibrations carried out.

The mechanical stop at the lower setting point serves as a reference value for calculating the current wear value.

The value is permanently stored in the tool memory and cannot be changed. Every time the battery is changed,

calibration must be carried out using this reference value. To do this, follow this procedure:

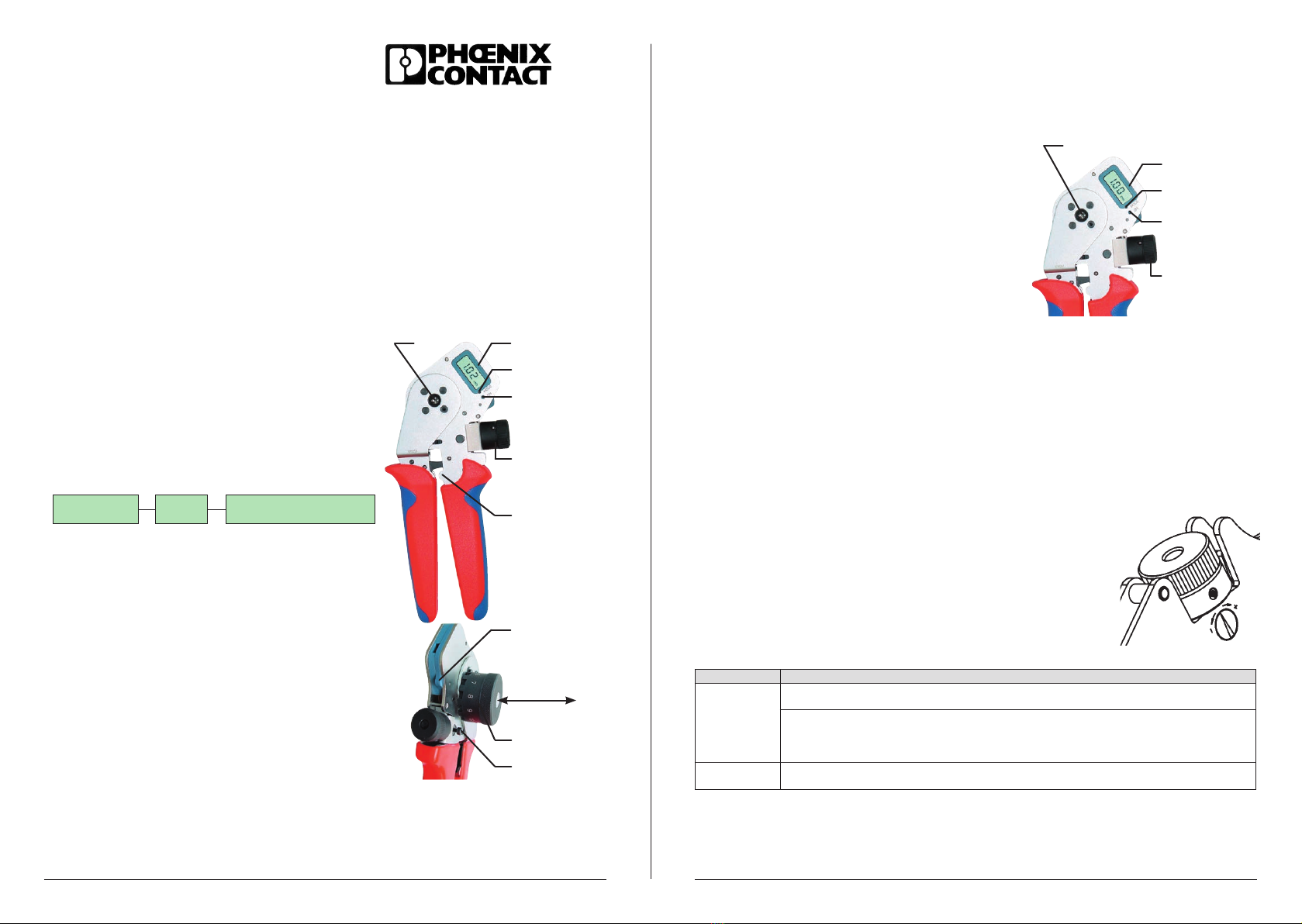

Calibrating the reference value

• For preparation, the battery must be removed.

• Open the pliers.

• Turn the adjustment knob to the stop at the lower setting point (turn counter-clockwise;

see gure) and leave it there.

• Insert battery; "CAL" appears on the display to prompt you to calibrate.

• Adjust the pliers with the gauge (see also section "Calibrating the pliers").

• Keep the "ON/OFF" button pressed and press the "MODE" button using the gauge.

Keep the "MODE" pressed for at least 5 seconds. Release the "MODE" button after 5

seconds and then the "ON/OFF" button.

• The digital display automatically jumps to the gauge value 1.0 mm.

• The pliers are adjusted and ready for the crimping parameters to be set.

Troubleshooting

Maintenance and repair

Unauthorized changes to or unintended use of the manual crimping pliers excludes the liability of the manufacturer for

any damage resulting from this.The manual crimping pliers must be clean and in good order before starting work. Any

residue from the crimping process must be removed from the crimping jaws and locator. The joints must be lubricated

regularly with a light machine oil and protected against dirt. Please ensure that all bolts are secured with circlips.

Repairs to the 4-arbor crimping pliers may only be carried out by the manufacturer of the pliers.

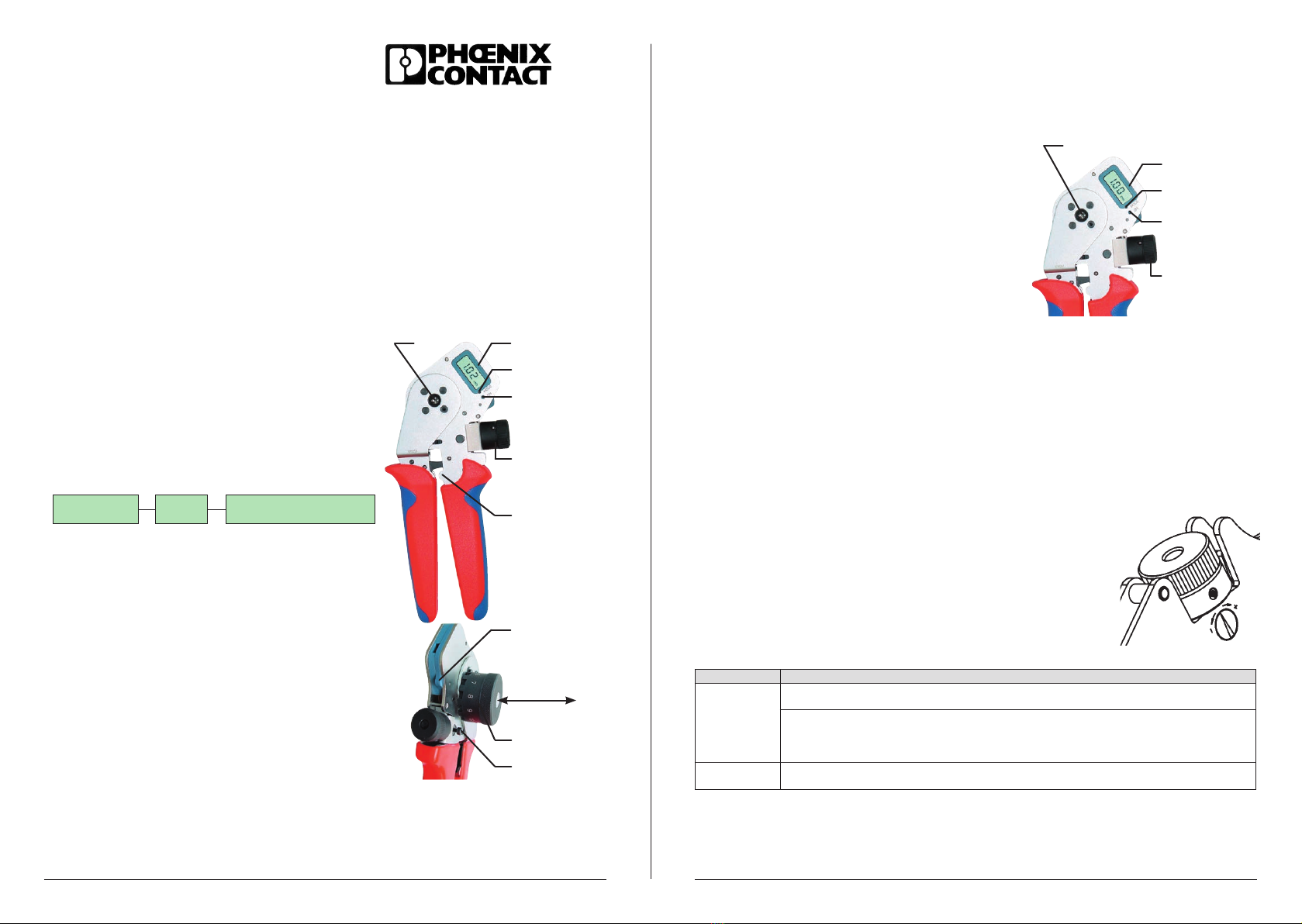

Gauge introduced

Gauge dimensions

displayed

"MODE" button

"ON/OFF" button

Adjustment knob for

setting the arbors to

the gauge dimension

1514560 (Page 1 / 3)

Operating Instructions SF-Z0054 • 2017-Apr.-20 Operating Instructions SF-Z0054 • 2017-Apr.-20

Displayed Cause / Solution

E1

After changing the battery: Rotate the adjustment wheel to the lowest setting before inserting the

battery. Next, calibrate the pliers. See the section "Calibrating the reference value".

After approximately 50,000 ... 200,000 cycles: E1 sporadically appears on the display with the

crimping setting, to indicate the wear limit has been reached. If E1 continues to appear on the

display, despite carrying out calibration repeatedly, the pliers are worn and must be sent in for

service.

E2 There is excessive play between the punch and the internal cylindrical gauge. Repeat the

calibration.

PHOENIX CONTACT GmbH & Co. KG

D-32823 Blomberg, Germany

Tel. +49(0)5235-300

Fax +49(0)5235-310799

www.phoenixcontact.com

info@phoenixcontact.com