IL ETH BK DI8 DO4 2TX-PAC

7275_en_09 PHOENIX CONTACT 10 / 37

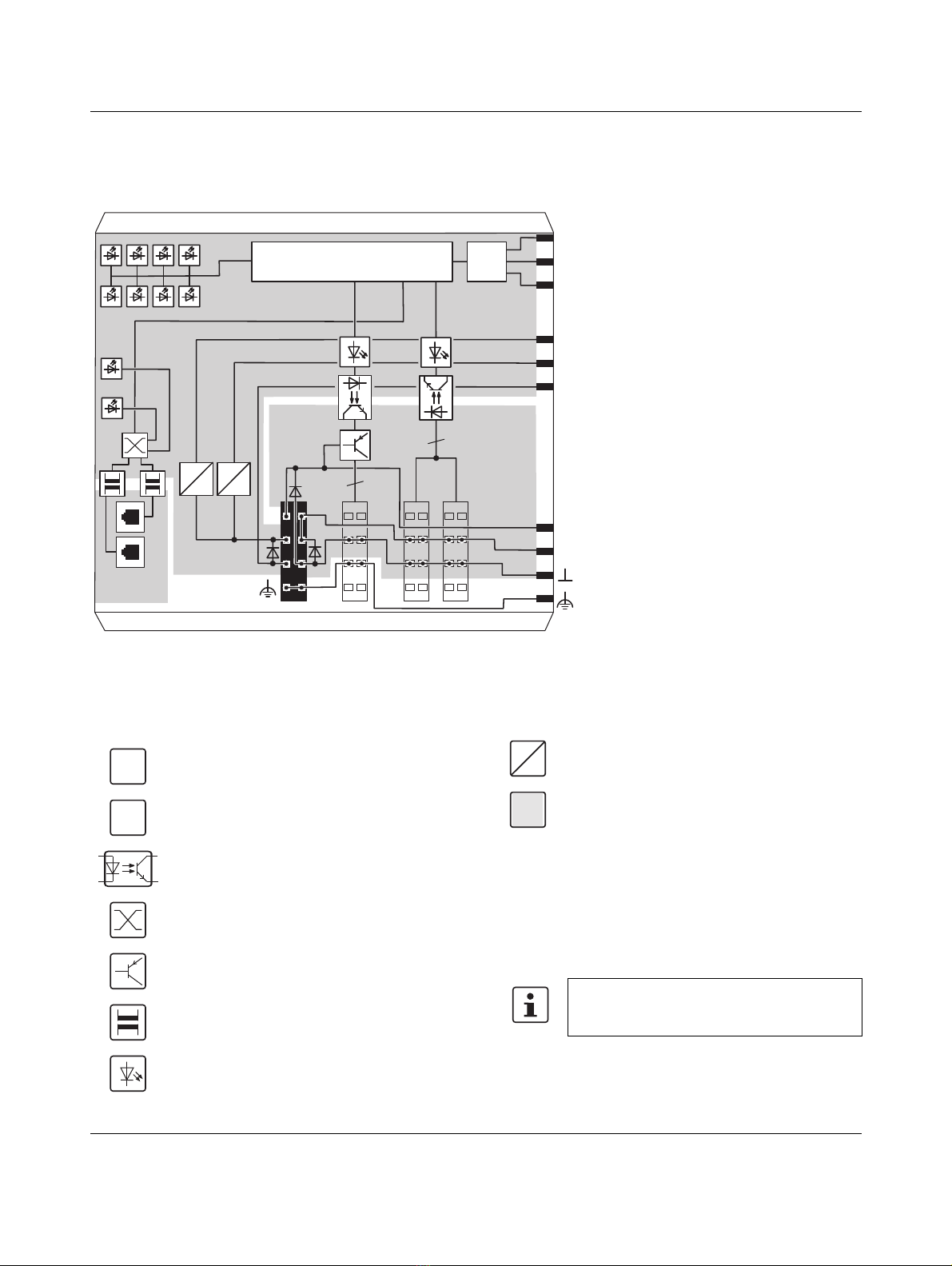

6 Notes on using the terminal block

in potentially explosive areas

Approval according to ATEX Directive 2014/34/EU

II 3 G Ex nA IIC T4 Gc X

Installation notes

The category 3 device is designed for installation in zone 2

potentially explosive areas.

The device meets the requirements of EN60079-0:2012 +

A11:2013 and EN60079-15:2010.

•Observe the specified conditions for use in potentially

explosive areas.

•At the time of installation, use an approved housing

(minimum protection IP54), which meets the

requirements of EN 60079-15. Within this context,

observe the requirements of IEC 60079-14/EN 60079-

14.

•The following work is only permitted in potentially

explosive areas when the power is disconnected:

•Connect the DIN rail to the protective earth ground.

•For reliable operation, the RJ45 plug needs to have a

fully functioning locking clip. Repair any damaged plugs

immediately.

•Only devices that are designed for operation in Ex Zone

2 and the conditions at the installation location may be

connected to the circuits in Zone 2.

•Make sure that the maximum permissible current of 4A

flowing through potential jumpers UMand US(total

current) is not exceeded.

•When using the device in potentially explosive areas,

observe the specifications in the application note

AHDEILEXZONE2 (German) / AHENILEXZONE2

(English).

7Safetynote

If possible, deactivate unused communication channels.

Assign passwords such that third-parties cannot access the

bus coupler and make changes without authorization.

Due to its communication interfaces, the bus coupler should

not be used in safety-critical applications without additional

security appliances.

Therefore, please take additional protective measures in

accordance with the IT security requirements and the

standards applicable to your application (e.g.virtual

networks (VPN) for remote maintenance access, firewalls,

etc.) for protection against unauthorized network access.

On first request, you shall release PhoenixContact and the

companies associated with

PhoenixContactGmbH&Co.KG, Flachsmarktstrasse8,

32825Blomberg in accordance with §§15ff.AktG (German

Stock Corporation Act), hereinafter collectively referred to

as "Phoenix Contact",

from all third-party claims made due to improper use.

For the protection of networks for remote maintenance via

VPN, PhoenixContact offers the mGuard product series as

security appliances; these are described in the latest

PhoenixContact catalog (phoenixcontact.net/products).

Additional measures for protection against unauthorized

network access can be found in the

AHENINDUSTRIALSECURITY application note. The

application note can be downloaded at phoenixcontact.net/

products.

WARNING: Explosion hazard

Please make sure that the following notes and

instructions are observed.

- Snapping the device onto the DIN rail

- Removing the device from the DIN rail

- Connection and disconnection of cables

NOTE: Risk of unauthorized network

access

Connecting devices to a network via Ethernet

entails the danger of unauthorized access to

the network.

To prevent unauthorized network access,

please read the following notes.