9

!!

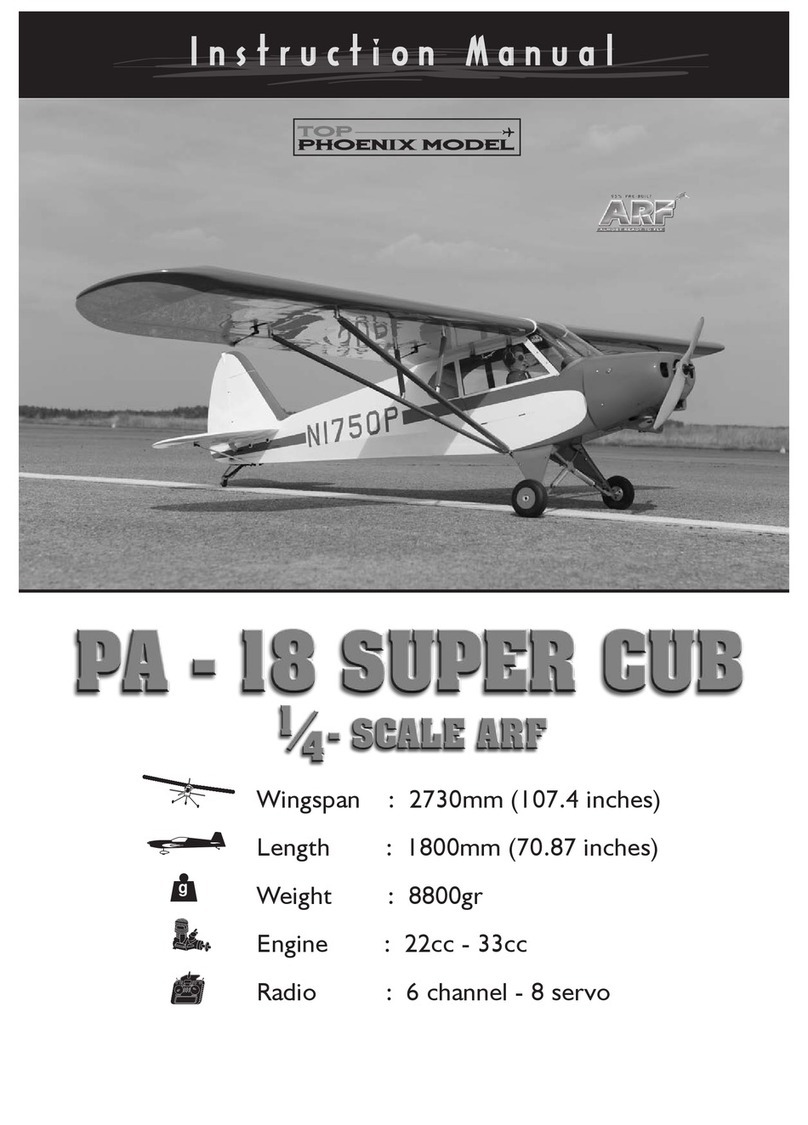

5. Test fit the stopper assembly into the tank. It

may be necessary to remove some of the

flashing around the tank opening using a

modeling knife. If flashing is present, make sure

none of it falls into the tank.

6. When satisfied with the alignment of the stopper

assembly tighten the 3mm x 20mm machine

screw until the rubber stopper expands and

seals the tank opening. Do not over tighten the

assembly as this could cause the tank to split.

7. Using a modeling knife, cut 3 lengths of fuel line

150mm long. Connect 2 lines to the 2 vent tubes

and 1 line to the fuel pickup tube in the stopper.

8. Feed three lines through the fuel tank

compartment and through the pre-drilled hole in

the firewall. Pull the lines out from behind the

engine, while guiding the fuel tank into place.

Push the fuel tank as far forward as possible, the

front of the tank should just about touch the back

of the firewall.

Blow through one of the lines to ensure the fuel

lines have not become kinked inside the fuel

tank compartment. Air should flow through

easily.

Do not secure the tank into place permanently

until after balancing the airplane. You may need

to remove the tank to mount the battery in the

fuel tank compartment.

9. To secure the fuel tank in place, apply a bead of

silicon sealer to the forward area of the tank,

where it exits the fuselage behind the engine

mounting box and to the rear of the tank at the

forward bulkhead.

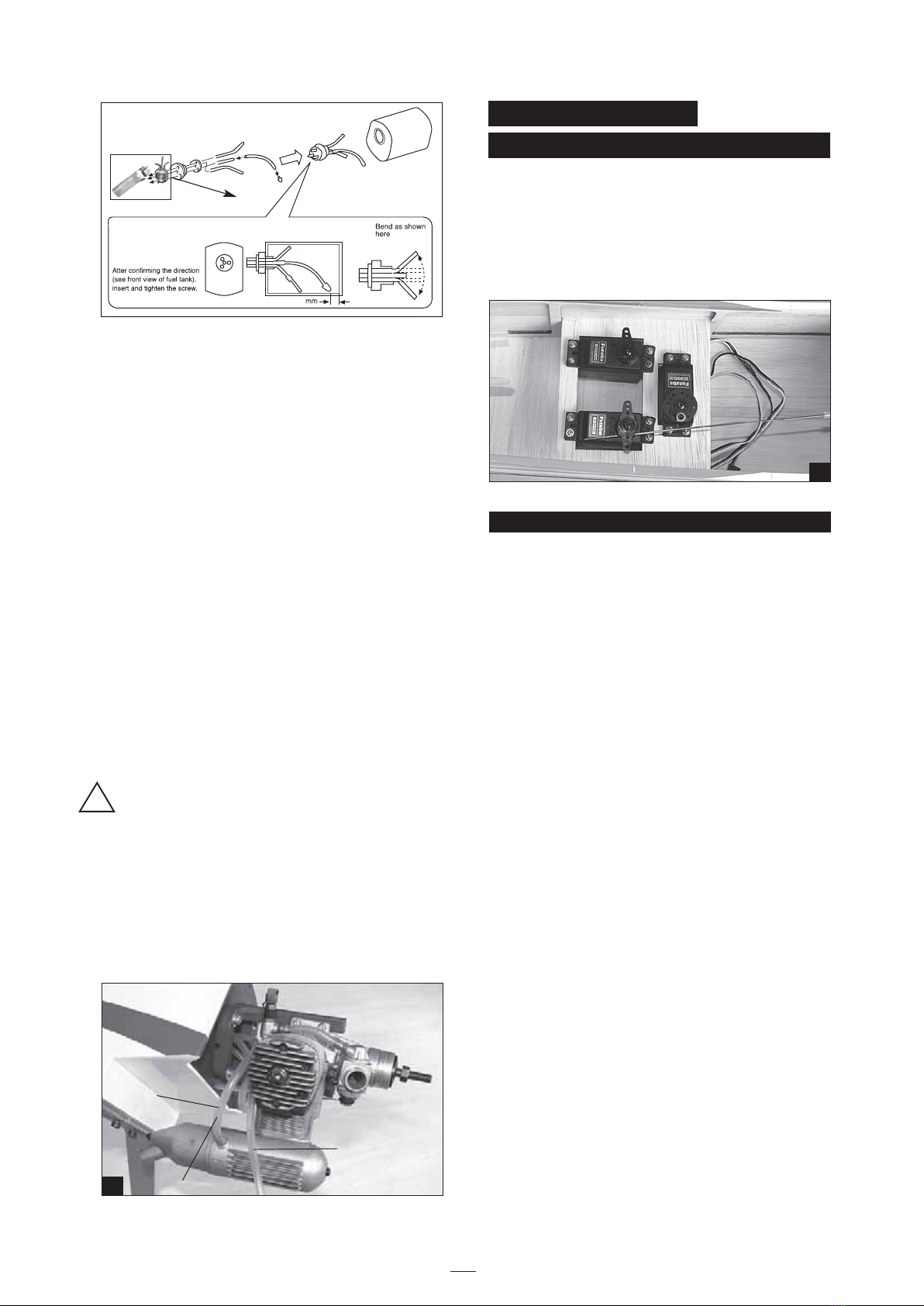

SERVO INSTALLATION

INSTALLING THE FUSELAGE SERVOS

1. Install the rubber grommets and brass collets

into the elevator, rudder and throttle servos. Test

fit the servos into the servo tray. Trim the tray if

necessary to fit your servos

2. Mount the servos to the tray using the mounting

screws provided with your radio system.

INSTALLING THE ELEVATOR PUSHROD

PARTS REQUIRED

· (1) Wire pushrod.

· (2) Clevis

· (2) Silicone tube

· (1) Nylon snap keeper

· (2) Nylon control horn w/plate

· (4) 2mm x 14mm sheet metal screw

· (2) Elevator pushrod

1. Locate the pushrod exit slot on the right side

and left side of the fuselage. It is located slightly

ahead and below the horizontal stabilizer.

2. Carefully cut away the covering material from

the slot.

3. Working from inside the fuselage, slide the

threaded end of the pushrod until it reaches the

exit slot. Carefully reach in with a small screw

driver and guide the pushrod out of the exit slot.

4. Install the clevis on the elevator pushrod. Make

sure 6mm of thread shows inside the clevis.

5. The control horn should be mounted on the

bottom, left side and right side of the elevator at

the leading edge, in line with the elevator

pushrod.

6. Drill two 1,6mm holes through the elevator using

the control horn as a guide and screw the

control horn in place.

7. Attach clevis to the third hole in the control horn.

Install a silicone tube on the clevis.

8. Locate one nylon servo arm, and using wire

cutters, remove all but one of the arms. Using a

2mm drill bit, enlarge the third hole out from the

center to accommodate the elevator pushrod wire.

9. Plug the elevator servo into the receiver and

center the servo. Install the servo arm onto the

servo. The servo arm should be perpendicular to

the servo and point toward the middle of the

fuselage.

To carburator

To muffler

To vent Tube

27

28

8