4Unpacking 13

5Installation 15

5.1 General Notes on Installation................................................................................... 15

5.2 Attaching the L-509 to a Surface .............................................................................. 17

5.3 Connecting the L-509 to the Protective Earth Conductor........................................ 20

5.4 Affixing the Load to the L-509 .................................................................................. 22

5.5 Building a Multi-Axis System .................................................................................... 24

5.5.1 General Notes on Building a Multi-Axis System .......................................... 24

5.5.2 Building an XY System.................................................................................. 24

5.5.3 Building a Z System...................................................................................... 27

5.6 Connecting the L-509 to a Controller ....................................................................... 30

5.7 Connecting the Power Adapter to the L-509 ........................................................... 31

6Startup 33

6.1 General Notes on Startup......................................................................................... 33

6.2 Starting and Operating the Positioner ..................................................................... 35

6.2.1 L-509 Entries in the PI Positioner Database ................................................ 36

7Maintenance 37

7.1 General Notes on Maintenance ............................................................................... 37

7.2 Performing a Maintenance Run ............................................................................... 37

7.3 Cleaning the L-509.................................................................................................... 37

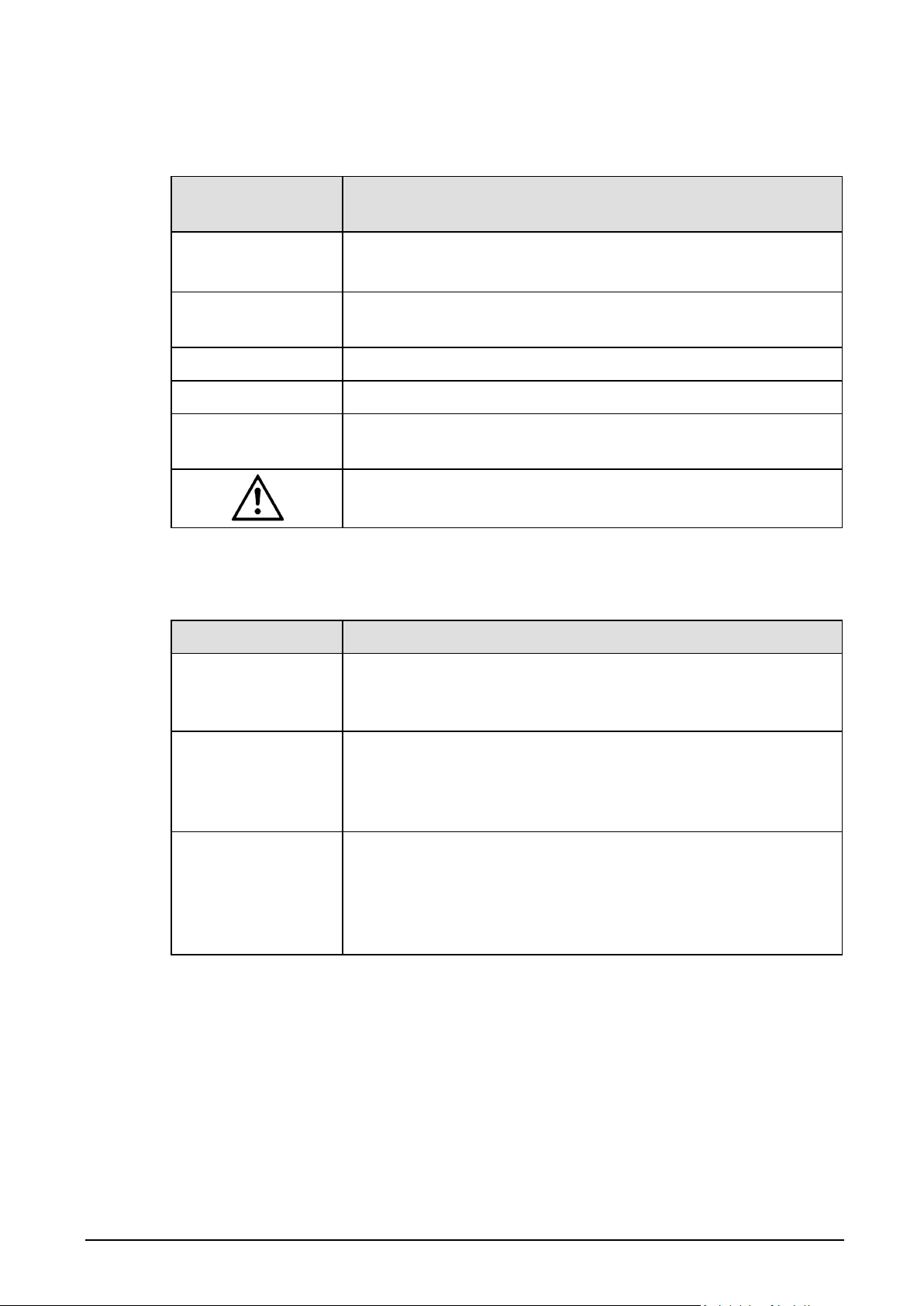

8Troubleshooting 39

8.1 Possible Causes and Remedies................................................................................. 39

8.2 Moving the Platform by Hand .................................................................................. 41

9Customer Service Department 43

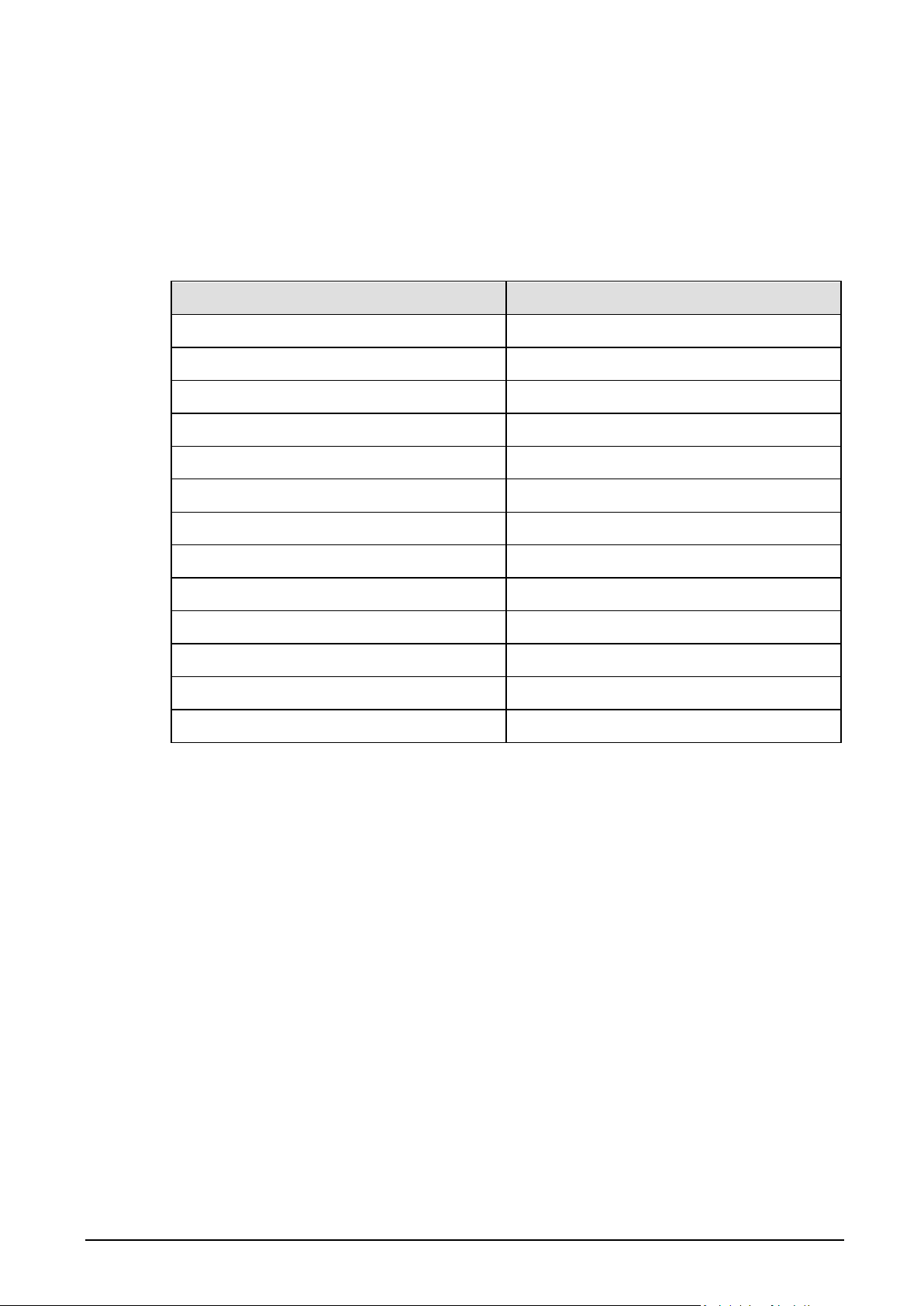

10 Technical Data 45

10.1 Specifications............................................................................................................ 45

10.1.1 Data Table.................................................................................................... 45