Table of Contents

1. INTRODUCTION .......................................................................................................................................1

2. SYSTEM OVERVIEW .................................................................................................................................2

ADVANTAGES OF MID-DRIVE MOTOR SYSTEMS ............................................................................................... 2

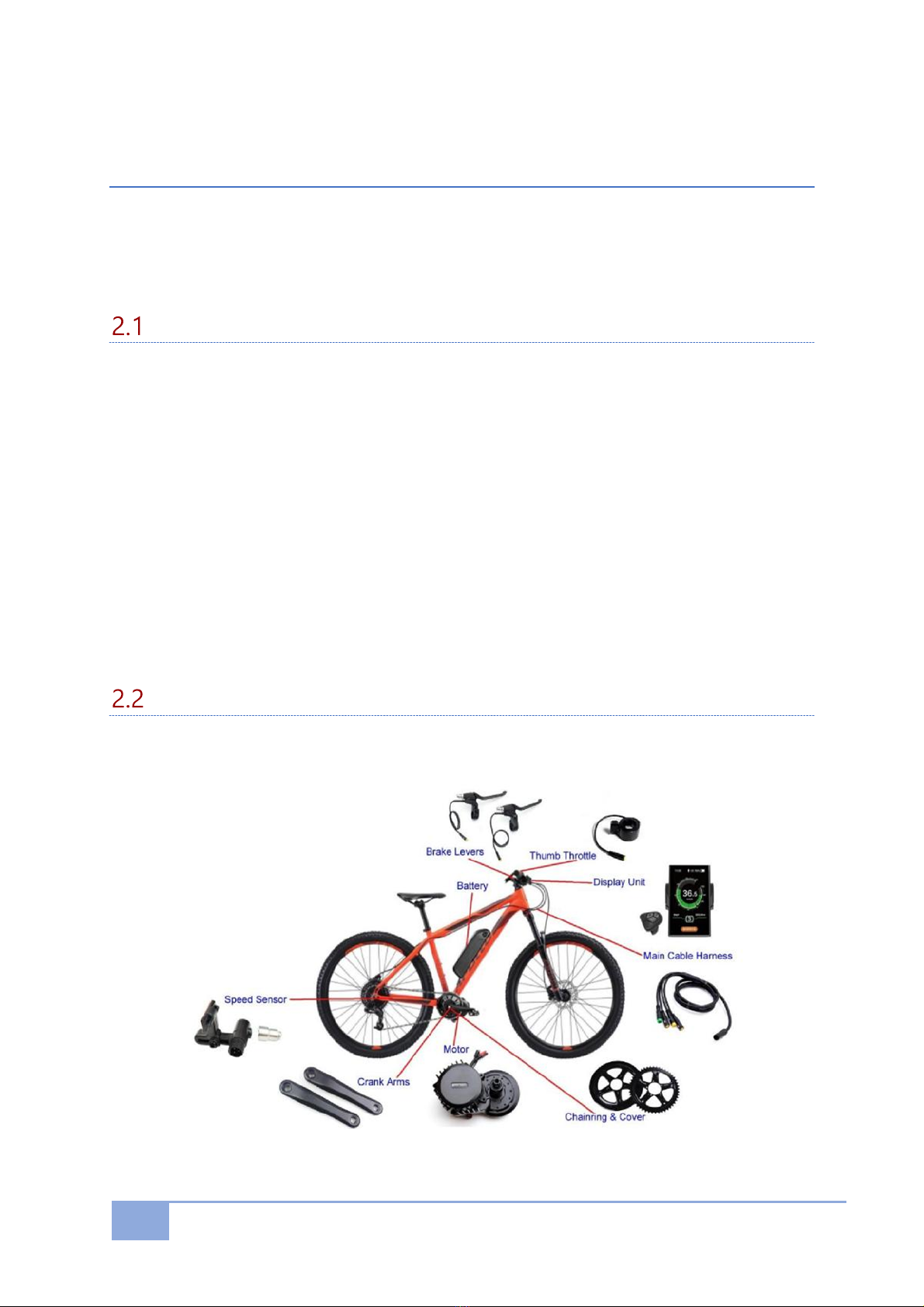

STANDARD ARRANGEMENT OF A MID-DRIVE SYSTEM ........................................................................................ 2

MOTOR CONSTRUCTION.............................................................................................................................. 3

SPECIFICATIONS ......................................................................................................................................... 3

PRECAUTIONS............................................................................................................................................ 3

3. PREPARATION .........................................................................................................................................4

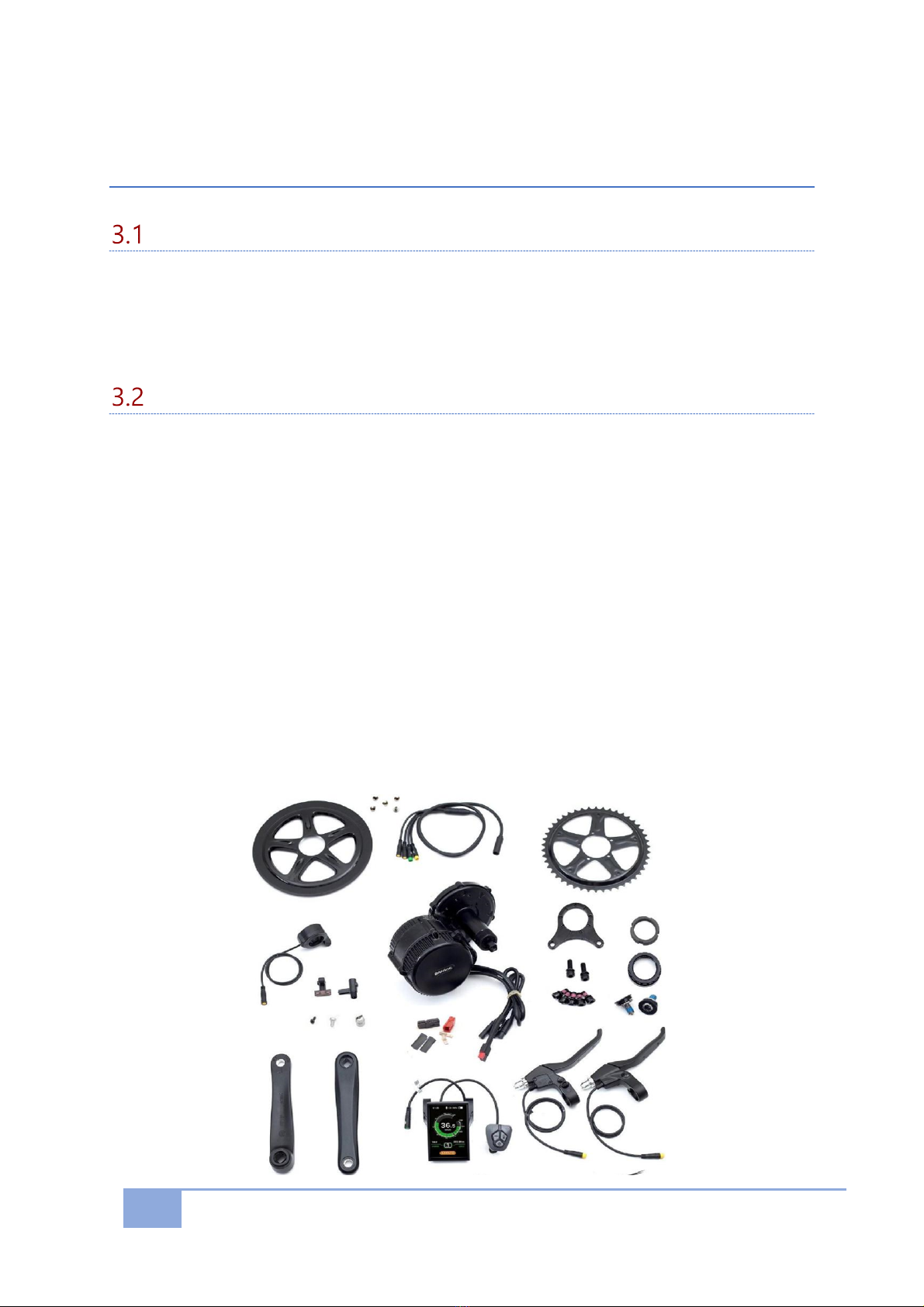

CONTENTS ................................................................................................................................................ 4

STANDARD CONVERSION KIT -COMPONENTS LIST ............................................................................................ 4

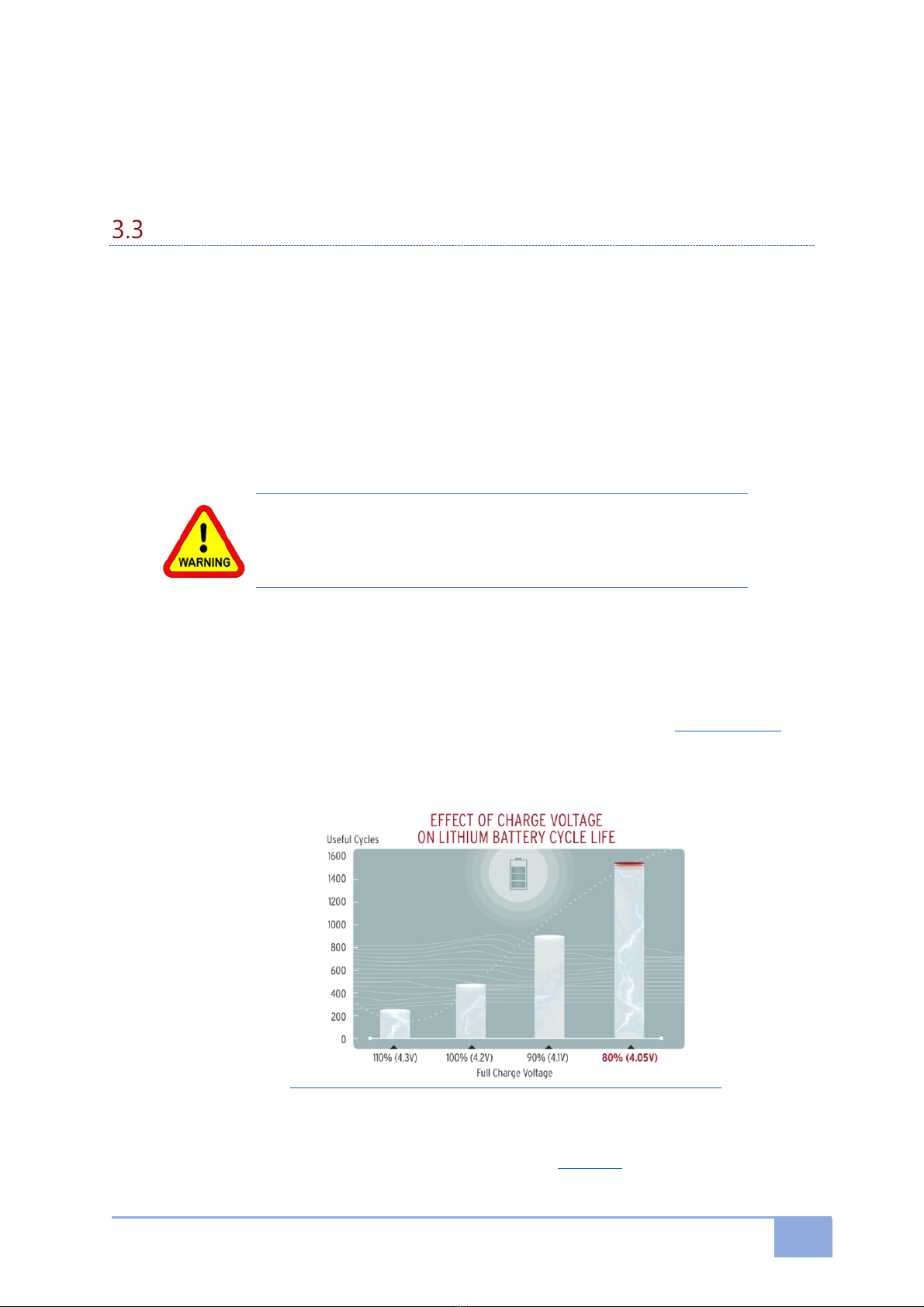

BATTERY PREPARATION ............................................................................................................................... 5

4. INSTALLATION PROCEDURE .....................................................................................................................6

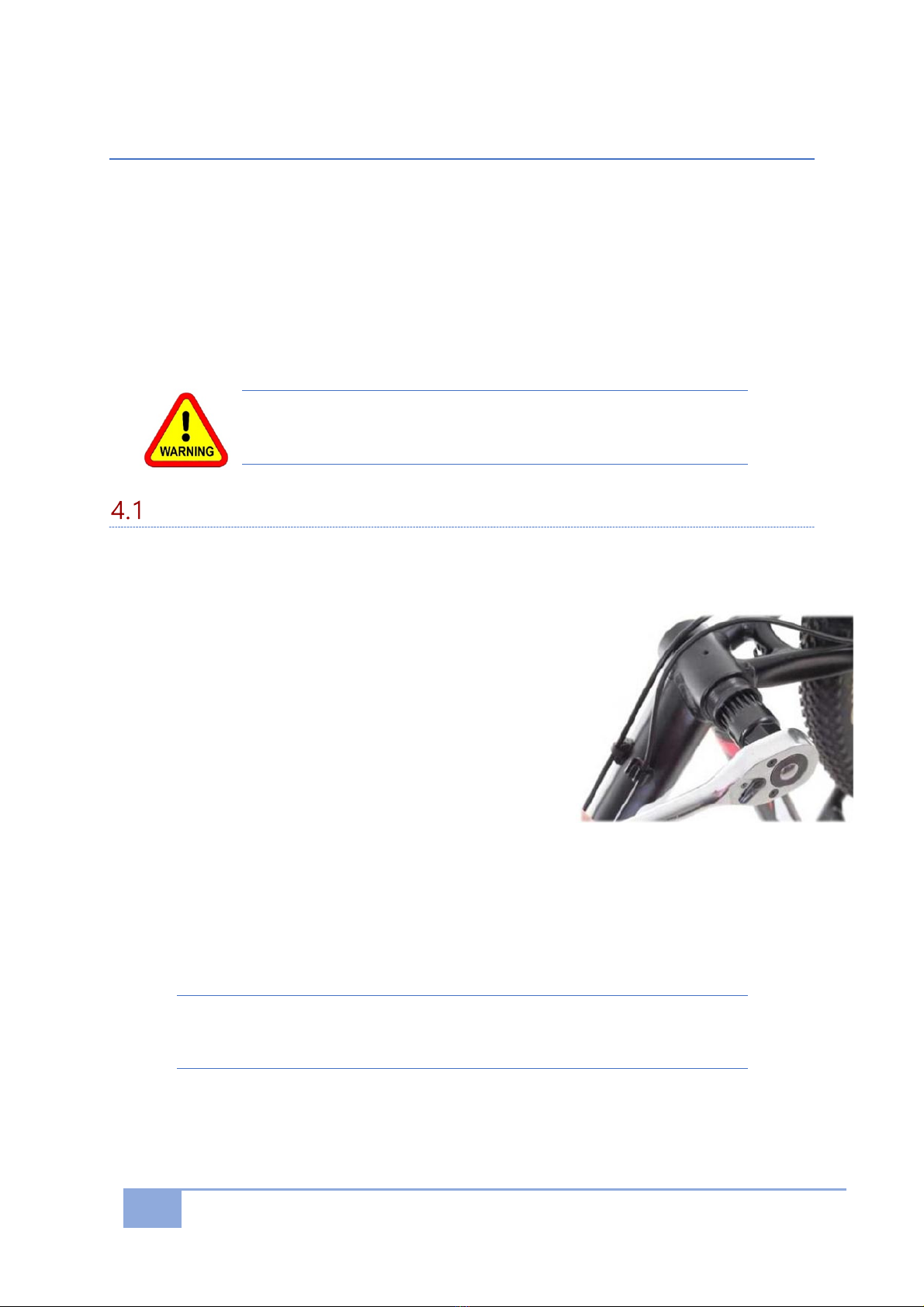

BOTTOM BRACKET REMOVAL ........................................................................................................................ 6

INSTALL THE MID-DRIVE MOTOR .................................................................................................................. 7

CHAIN RING SIZE ........................................................................................................................................ 9

CHECK THE CHAIN LINE .............................................................................................................................. 10

4.4.1 Narrow-wide tooth pattern ............................................................................................................ 10

4.4.2 Chainring upgrades......................................................................................................................... 11

4.4.3 Lekkie Benefits ................................................................................................................................ 11

4.4.4 Chainring Adapters ......................................................................................................................... 12

INSTALL THE BATTERY ............................................................................................................................... 12

INSTALL THE DISPLAY UNIT......................................................................................................................... 13

INSTALL THE BRAKE CONTROLS ................................................................................................................... 13

4.7.1 E-Brakes ......................................................................................................................................... 14

4.7.2 Brake Sensors.................................................................................................................................. 14

INSTALL THE THROTTLE.............................................................................................................................. 15

INSTALL THE SPEED SENSOR ....................................................................................................................... 16

INSTALL THE CABLING ................................................................................................................................ 16

CABLE IDENTIFICATION CHART .................................................................................................................... 17

FINALISE &NEATEN.................................................................................................................................. 18

5. SYSTEM VERIFICATION .......................................................................................................................... 18

6. OPTIONAL EXTRAS................................................................................................................................. 19

BOTTOM BRACKET -SPACERS &WASHERS ................................................................................................... 19

STABILISER BARS ...................................................................................................................................... 19

6.2.1 Non-full suspension......................................................................................................................... 19

6.2.2 Full suspension ................................................................................................................................ 19

GEAR SENSORS ........................................................................................................................................ 20

KILL SWITCH............................................................................................................................................ 20

7. GENERAL CARE & MAINTENANCE .......................................................................................................... 21

INSTALLATION AND MAINTENANCE SERVICING ............................................................................................... 21

TROUBLESHOOTING ERROR CODES .............................................................................................................. 22

8. WARRANTY ........................................................................................................................................... 23