9/30

5.9ResetinputThe following error states due to a failure external to the device can be rest using the

I3 input:

- a short circuit or overload of safety outputs (OS1, OS2),

- a short circuit between a safety output and the supply voltage.

5.10Replacementoftheactuator(forarticlesST••4••••,ST••8••••only)Attention: The machine manufacturer must restrict access to the sensor pro-

gramming mode to authorised personnel only.

Via input I3 it is possible to replace the coded actuator with a second actuator at any

time. This operation is repeatable an unlimited number of times. After programming

has been completed, the sensor will recognise only the actuator code corresponding

to the last executed programming operation.

1) Power the sensor at the rated voltage. The sensor carries out internal tests. The

LED illuminates as described in paragraph OPERATING STATES.

2) Activate the I3 programming input, by applying the voltage Ue1 (see paragraph

TECHNICAL DATA). The LED illuminates purple to indicate it is ready to receive the

new code to be stored.

3) Move the new actuator towards the sensor, with the centring symbols aligned. The

LED flashes green twice, once programming has completed successfully.

4) Disable the I3 programming input: the sensor restarts automatically and repeats the

internal tests to switch to the RUN operating state.

The second actuator must be suitably fixed to the guard as described in paragraph

INSTALLATION INSTRUCTIONS. Once the operation is carried out, check recognition

of the newly programmed actuator and perform the sequence of functional tests

specified in these operating instructions.

This operation must not be carried out as a repair or maintenance operation. If the

device ceases to function correctly, replace the entire device and not just the actuator.

The programming operation of the actuator can be carried out either with the

safety inputs deactivated or with the safety inputs activated.

6 INSTRUCTIONS FOR PROPER USE

6.1 Installation

Attention: Installation must be carried out by qualified staff only. The OS1

and OS2 safety outputs of the device must be connected to the safety circuit of

the machine. The signalling output O3 is not a safety output and may not be used

individually in a safety circuit to determine safe state of guard closed.

- Do not stress the device with bending and torsion.

- Do not modify the device for any reason.

- Do not exceed the tightening torques specified in the present operating instructions.

- The device carries out an operator protection function. Any inadequate installation

or tampering can cause serious injuries and even death, property damage, and

economic losses.

- These devices must not be bypassed, removed, turned or disabled in any other way.

- If the machine where the device is installed is used for a purpose other than that

specified, the device may not provide the operator with efficient protection.

- The safety category of the system (according to EN ISO 13849-1), including the safe-

ty device, also depends on the external components connected to it and their type.

- Before installation, make sure the device is not damaged in any part.

- Avoid excessive bending of connection cables in order to prevent any short circuits

or power failures.

- Do not paint or varnish the device.

- Do not drill the device.

- Do not use the device as a support or rest for other structures, such as raceways,

sliding guides or similar.

- Before commissioning, make sure that the entire machine (or system) complies with

all applicable standards and EMC directive requirements.

- The fitting surface of the device must always be smooth and clean.

- The documentation required for correct installation and maintenance is available

online in various languages on the Pizzato Elettrica website.

- Should the installer be unable to fully understand the documents, the product must

not be installed and the necessary assistance may be requested (see paragraph

SUPPORT).

- Before commissioning the machine, and periodically, check for correct switching of

the outputs and correct operation of the system comprising the device and associ-

ated safety circuit.

- In proximity of the device do not carry out arc welding, plasma welding, or any other

process that may generate electromagnetic fields of intensity higher than the limits

prescribed by the standards, even when the sensor is off.Where welding operations

are to be carried out in the proximity of a previously installed device, it must first be

moved away from the work area.

- No work that can cause high-intensity electrostatic discharges (e.g. stripping or rub-

bing plastic surfaces or other materials that can be electrostatically charged) may

be carried out in the vicinity of devices that are supplied with electrical energy, even

if they are switched off or not wired.

- Always attach the following operating instructions to the manual of the machine in

which the device is installed.

- These operating instructions must be kept available for consultation at any time and

for the whole period of use of the device.

6.2 Do not use in the following environments

- In environments where the application causes collisions, impacts or strong vibrations

to the device.

- In environments containing explosive or inflammable gases or dusts.

- In environments where ice can form on the device.

- In environments with strong and sudden temperature changes. For example in hot

working environments where cleaning with cold water is performed. In these cases

it is advisable to protect the sensor with suitable shields.

- In environments containing strongly aggressive chemicals, where the chemical prod-

ucts used coming into contact with the device may impair its physical or functional

integrity. Always check before installation the chemical compatibility between the

materials of which the device is made (see paragraph TECNICAL DATA) and the

chemical products that could come into contact with the device.

- Prior to installation, the installer must always ensure that the device is suitable for

use under the ambient conditions on site.

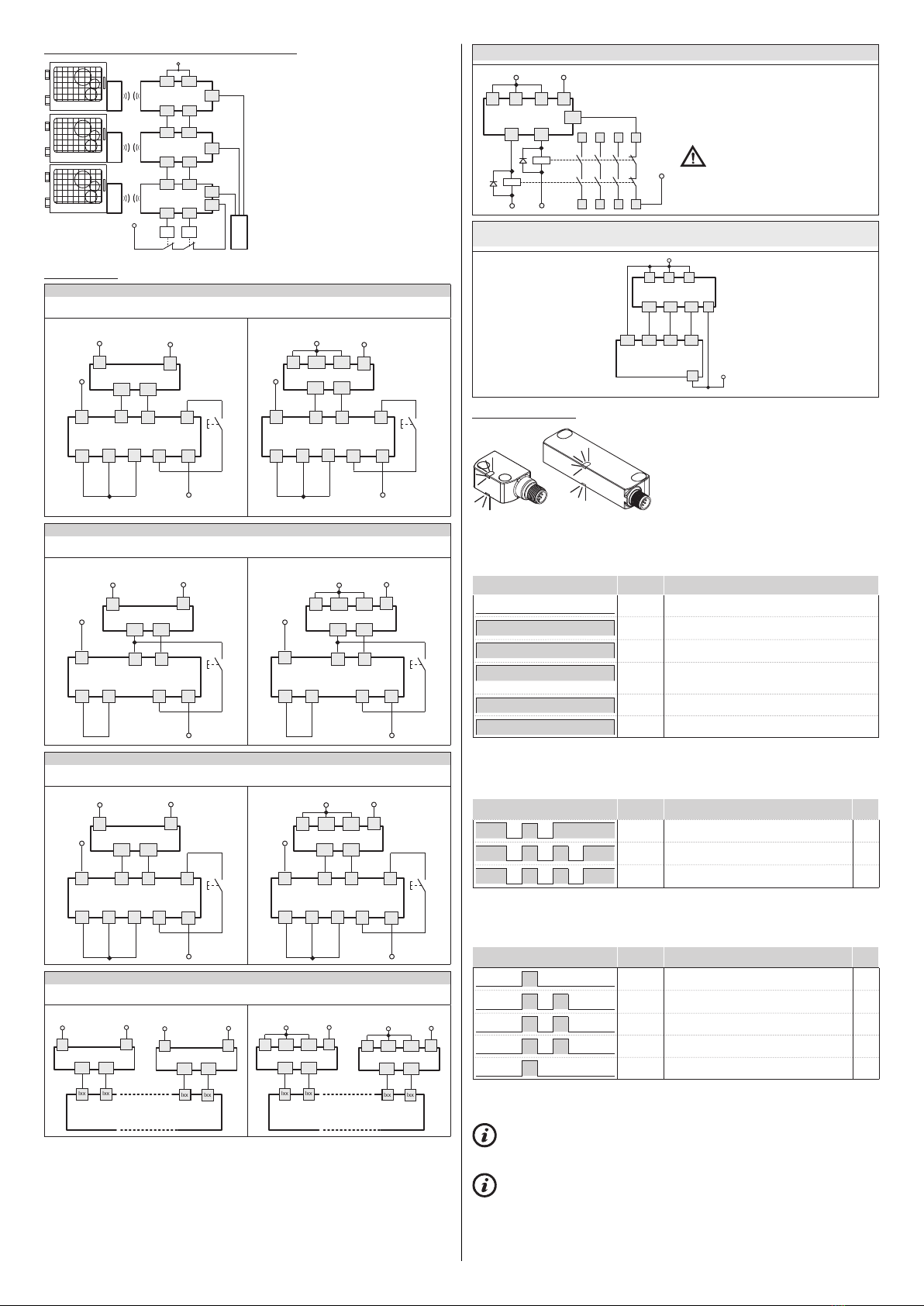

6.3 Mechanical stop

Attention: The door must always be provided with an independent end-limit

mechanical stop at limit of travel.

Do not use the device as mechanical stop for the door. The actuator must not strike

the sensor.

6.3.1 Versions with holding magnet

The devices with an internal magnet allow to generate a

holding force between the sensor and the actuator that can

keep the guard shut even if there are vibrations.

The magnetic holding force is available in various magnitudes

that can be chosen depending on the application (see

paragraph TECHNICAL DATA).

6.4 Maintenance and functional tests

Attention: Do not disassemble or try to repair the device. In case of any

malfunction or failure, replace the entire device.

Attention: In case of damages or wear it is necessary to change the whole

device including its actuator. Correct operation cannot be guaranteed when the device

is deformed or damaged.

- The installer is responsible for establishing the sequence of functional tests to which

the device is to be subjected before the machine is started up and during maintenance

intervals.

- The sequence of the functional tests can vary depending on the machine complexity

and circuit diagram, therefore the functional test sequence detailed below is to be

considered as minimal and not exhaustive.

- Perform the following sequence of checks before the machine is commissioned and

at least once a year (or after a prolonged shutdown):

1) Open the guard while the machine is moving. The machine must stop immediately.

The stopping time of the machine must be always shorter than the time required by the

operator for opening the guard and reaching the dangerous parts.

2) Try to start the machine while the guard is open. The machine must not start.

3) Check correct actuator to device alignment.

4) Check that no external parts are damaged. If damaged, replace the entire device.

5) The actuator must be securely locked to the door; make sure that none of the machine

operator’s tools can be used to disconnect the actuator from the door.

- The device has been created for applications in dangerous environments, therefore

it has a limited service life. Although still functioning, after 20 years from the date

of manufacture the device must be replaced completely. The date of manufacture is

placed next to the product code (see paragraph MARKINGS).

6.5 Wiring

Attention: Check that the supply voltage is correct before powering the device.

- Keep the charge within the values specified in the electrical operation categories.

- Only connect and disconnect the device when the power is off.

- Do not open the device for any reason.

- Discharge static electricity before handling the product by touching a metal mass

connected to earth. Any strong electrostatic discharge could damage the device.

- Power the safety switch and the other devices connected to it from a single SELV/

PELV source and in accordance with the applicable standards.

- Always connect the protection fuse (or equivalent device) in series with the power

supply for each device.

- During and after the installation do not pull the electrical cables connected to the

device.

- For devices with integrated cable, the free end of the cable (if it does not have a con-

nector) must be properly connected inside a protected housing. The cable must be

adequately protected from cuts, impacts, abrasion, etc.

6.6 Additional prescriptions for safety applications with operator protection

functions

Provided that all previous requirements for the devices are fulfilled, for installations

with operator protection function additional requirements must be observed.

- The utilization implies knowledge of and compliance with following stand-

ards: EN 60947-5-3, EN ISO 13849-1, EN 62061, EN 60204-1, EN ISO 14119,

EN ISO 12100.

6.7Limitsofuse- Use the device following the instructions, complying with its operation limits and the

standards in force.

- The devices have specific application limits (min. and max. ambient temperature,

mechanical endurance, IP protection degree, etc.) These limitations are met by the

device only if considered individually and not as combined with each other.

- The manufacturer’s liability is to be excluded in the following cases:

1) Use not conforming to the intended purpose;

2) Failure to adhere to these instructions or regulations in force;

3) Fitting operations not carried out by qualified and authorized personnel;

4) Omission of functional tests.

- For the cases listed below, before proceeding with the installation contact our techni-

cal assistance service (see paragraph SUPPORT):

a) In nuclear power stations, trains, airplanes, cars, incinerators, medical devices or

any application where the safety of two or more persons depend on the correct opera-

tion of the device;

b) cases not listed in these operating instructions.