- 3 -

IDF

GB S

E

NL

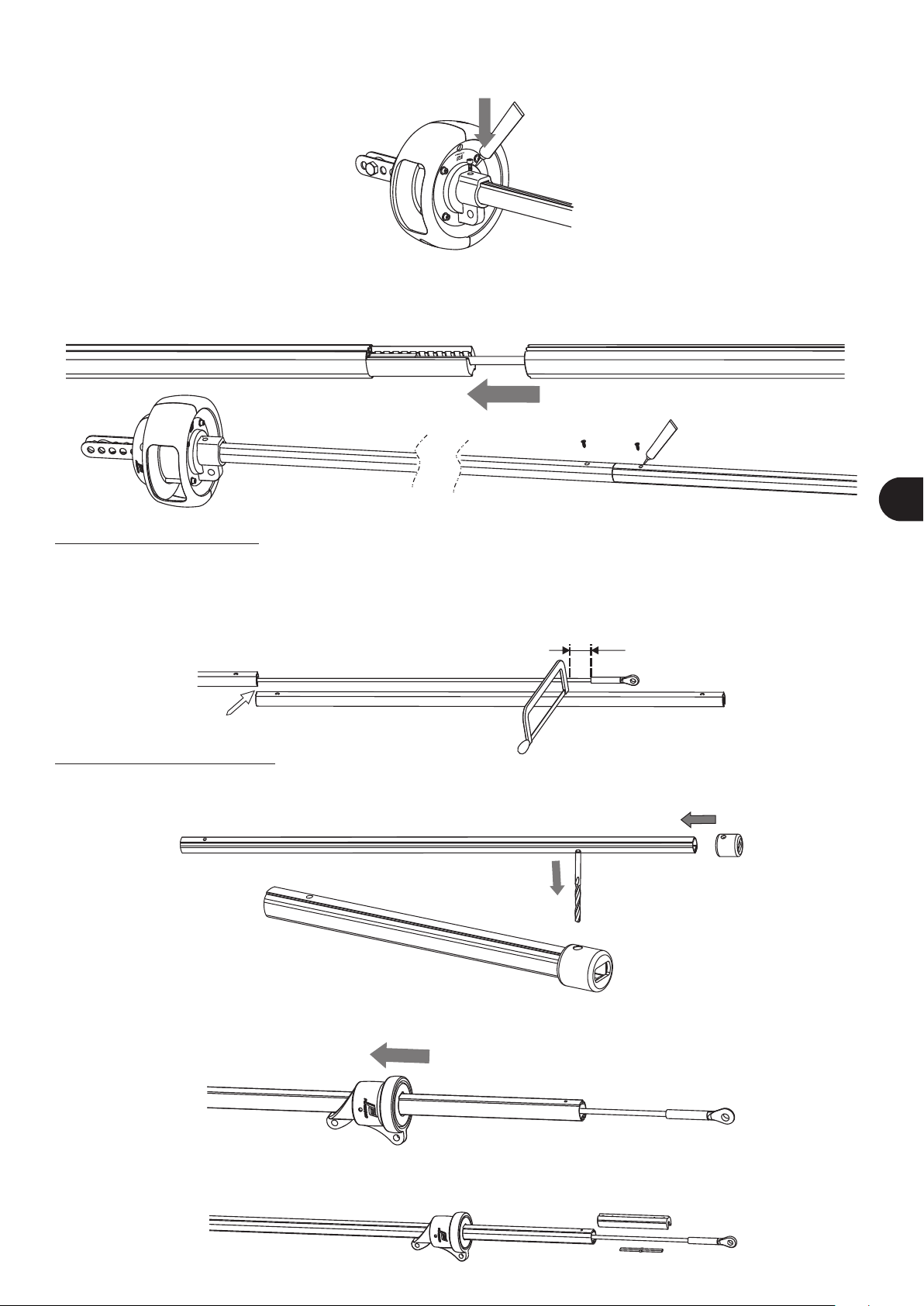

latte Terminal-

montage

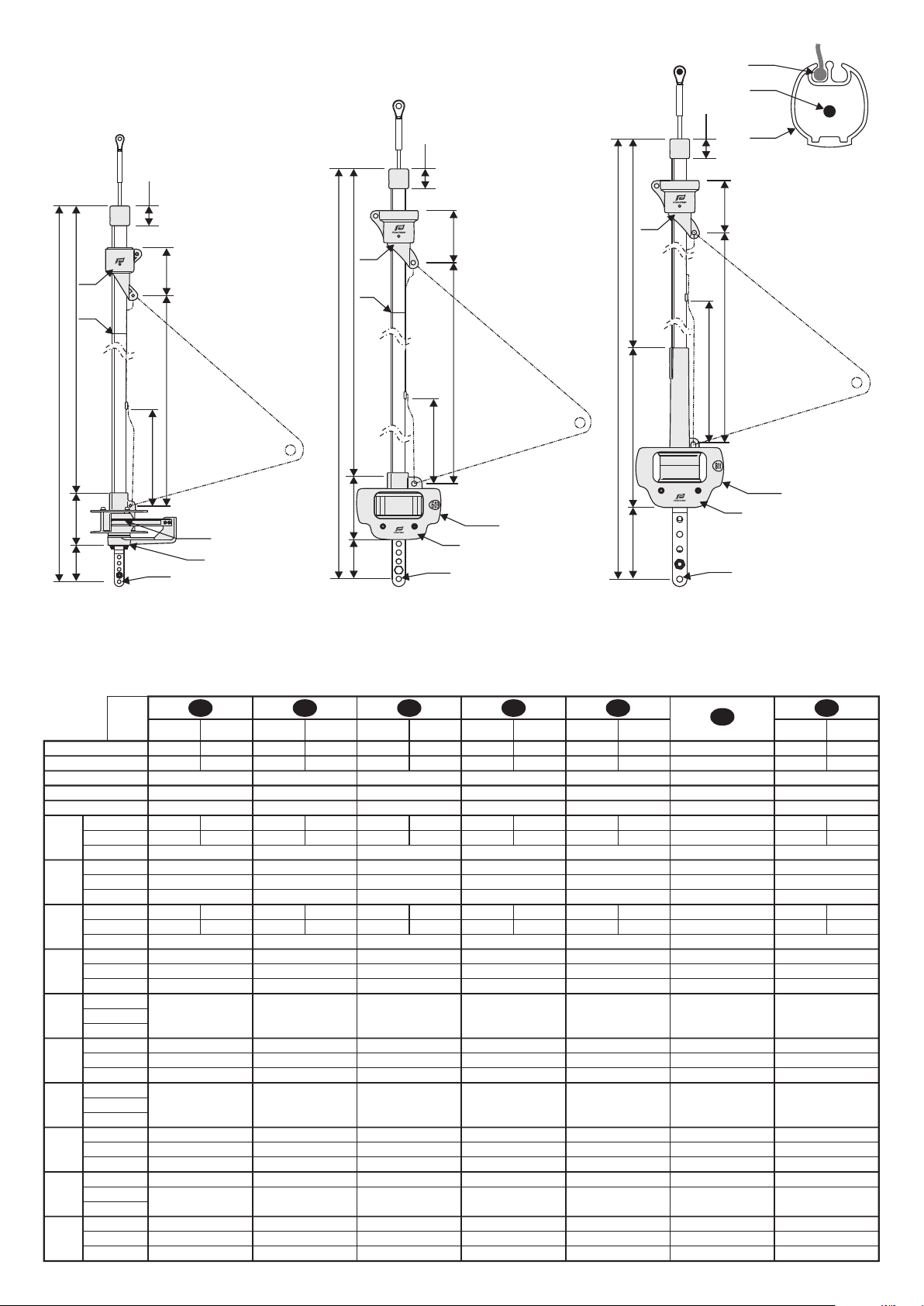

chainplate ridoirturnbuckle

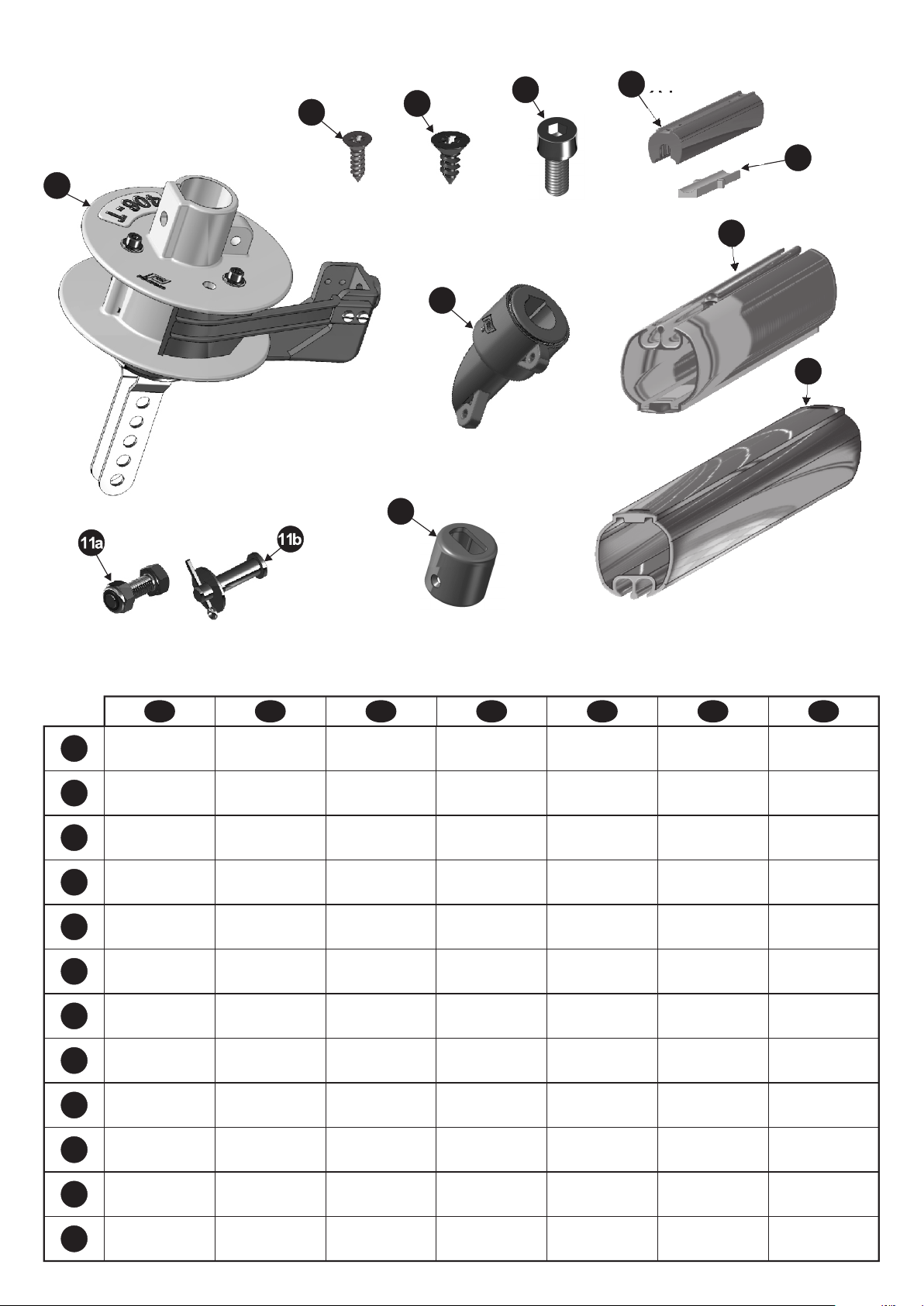

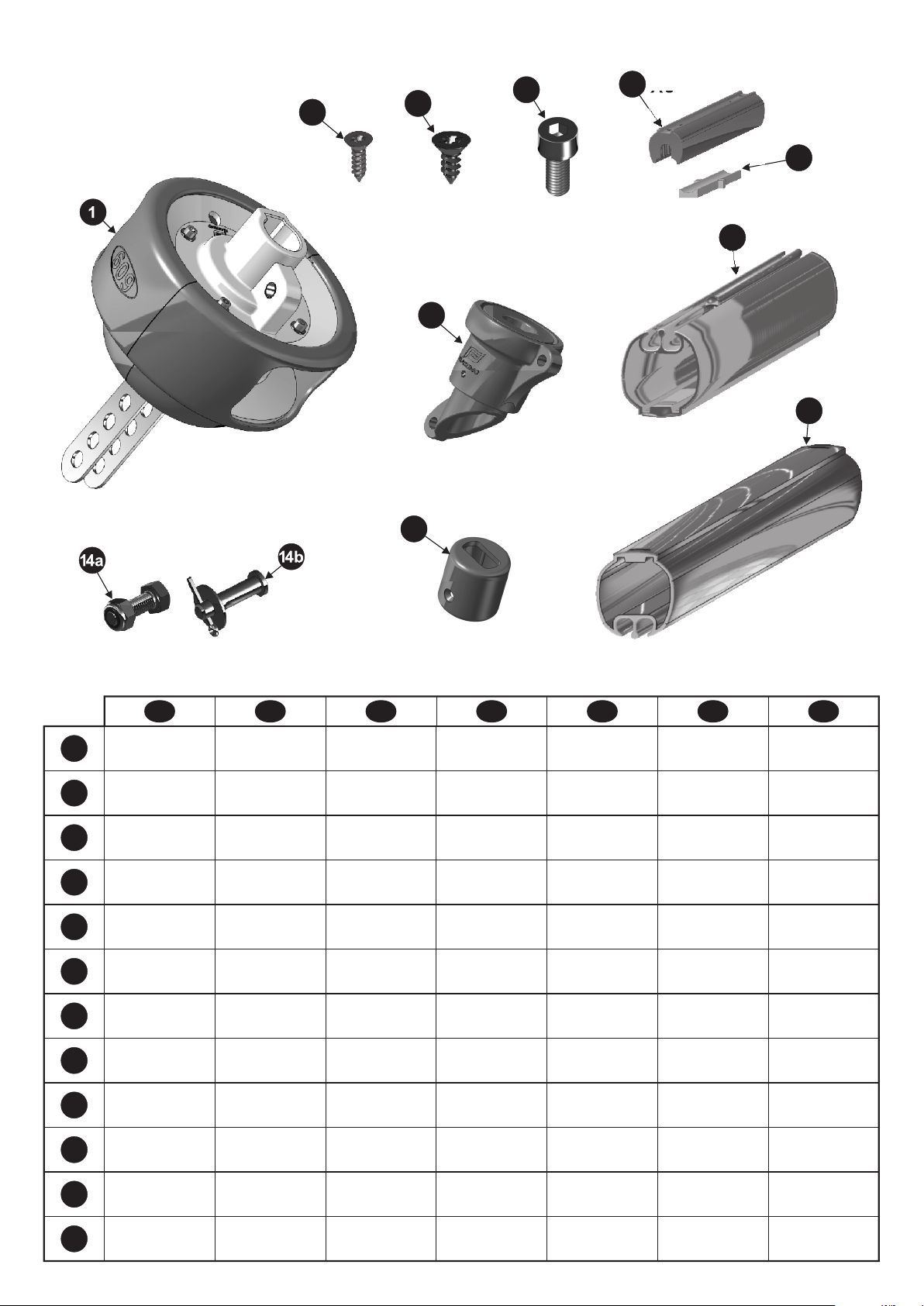

406-T

609-T

811-T

25200 25200 25200 25200 25200 25200

58207 58207 58207 58207 58207 58207

58209 58209 58209 58209 58209 58209 58209

25286 25286 25286 25286 25286 25286 25286

58208 58208 58208 58208 58208 58208 58208

ØA

ØB étai : Ø4-7mm Vorstag : Ø4-7mm voorstag : Ø4-7mm estay : Ø4-7mm Förstags : Ø4-7mm Strallo : Ø4-7mmforestay : Ø4-7mm ralingue :Ø5mm Vorliek :Ø5mm voorlijk :Ø5mm relinga :Ø5mm Lik :Ø5mm ralinga :Ø5mmluffrope : Ø5mm

811-T

406-T

609-T

C6.60m 6.60m 6.60m 6.60m 6.60m 6.60m6.68m 6.68m 6.68m 6.68m 6.68m 6.68m 6.68m

8.79m 8.79m 8.79m 8.79m 8.79m 8.79m9.40m8.96m 8.96m 8.96m 8.96m 8.96m 8.96m 8.96m

11.26m 11.26m 11.26m 11.26m 11.26m 11.26m 11.26m

811-T

406-T

609-T

D

2

12m 2

12m 2

12m 2

12m 2

12m 2

12m

2

12m 2

25m 2

25m 2

25m 2

25m 2

25m 2

25m

2

25m 2

35m 2

35m 2

35m 2

35m 2

35m 2

35m

2

35m

E

811-T

406-T

609-T 65mm 65mm 65mm 65mm 65mm 65mm150mm 150mm 150mm 150mm 150mm 150mm 150mm

115mm 115mm 115mm 115mm 115mm115mm 285mm 285mm 285mm 285mm 285mm 285mm285mm

220mm 220mm 220mm 220mm 220mm 220mm220mm

811-T

406-T

609-T

F6.22m 6.22m 6.22m 6.22m 6.22m 6.22m 6.22m

8.36m 8.36m 8.36m 8.36m 8.36m 8.36m 8.36m

10.70m 10.70m 10.70m 10.70m 10.70m 10.70m 10.70m

G

811-T

406-T

609-T 2 gorge 2 Nuten 2 zeilgroeven 2 relingas 2 likrännor 1 gole2 groove

811-T

406-T

609-T

ØH 8.5mm 8.5mm 8.5mm 8.5mm 8.5mm 8.5mm8.5mm 12.5mm 12.5mm 12.5mm 12.5mm 12.5mm 12.5mm12.5mm 14.3mm 14.3mm 14.3mm 14.3mm 14.3mm 14.3mm14.3mm

J

811-T

406-T

609-T jonctions Delrin

+ vis Verbindungen

Delrin +Schrauben koppelstuk

Delrin + schroeven Empalmes Delrin

+ tornillos Kopplïngar Delrin

+ skruv Giunzione Delrin

+ vite

coupling units :

Delrin+screws

R1811-T

406-T

609-T roulement Delrin Kugellager Delrin lagering Delrin Rodamientos Delrin Kullager Delrin cuscinetti Delrinbearing: Delrin roulement Delrin,inox Kugellager Delrin,inox lagering Delrin,RVS Rod. Delrin,inox Kulla. Delrin,rostfritt cuscinetti Delrin,inoxbearing: Delrin,inox roulement Delrin, TorlonKugellager Delrin, Torlon lagering Delrin, Torlon Rod. Delrin, Torlon Kulla. Delrin, Torlon cusci. Delrin, Torlonbearing: Delrin, Torlon

R2

811-T

406-T

609-T roulement Delrin Kugellager Delrin lagering Delrin Rodamientos Delrin Kullager Delrin cuscinetti Delrinbearing: Delrin

roulement

Delrin, Torlon Kugellager

Delrin, Torlon lagering

Delrin, Torlon Rodamientos

Delrin, Torlon Kullager

Delrin, Torlon cuscinetti

Delrin, Torlon

bearing:

Delrin, Torlon

811-T

406-T

609-T

S

6.35m 6.35m 6.35m 6.35m 6.35m 6.35m 6.35m

8.50m 8.50m 8.50m 8.50m 8.50m 8.50m 8.50m

10.44m 10.44m 10.44m 10.44m 10.44m 10.44m10.44m

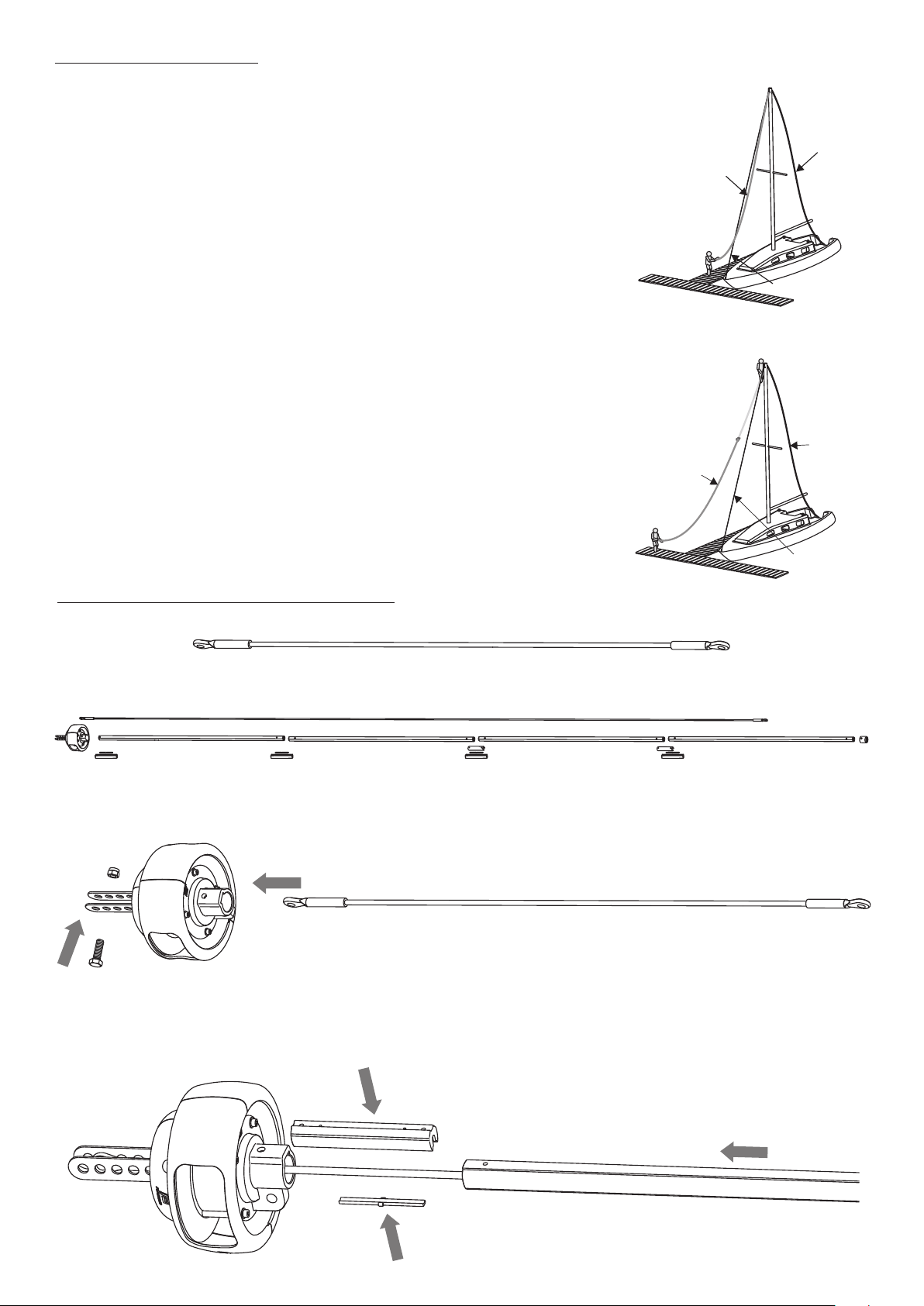

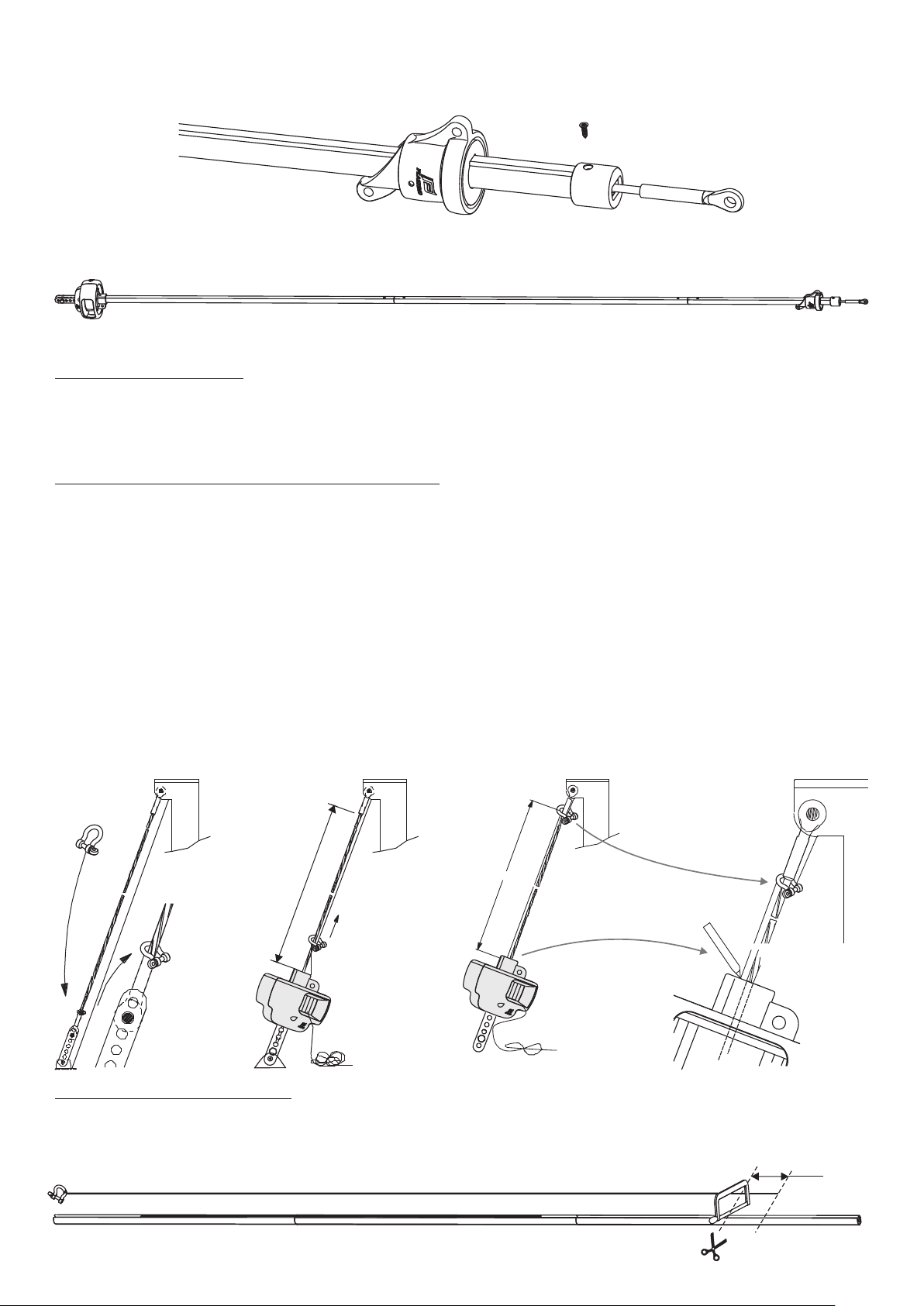

Stagspanner-

montage stevenplaa-

tuitvoering spanschroe-

fuitvoering placas tensor Landre Arridatoi

120

C

D

45

110

775

Ø145

ØH

F

E

406-T 609-T 811-T

S

R1

R2

J

S

45

R1

Ø190

ØH

E

C

136 D

765

F118

R2

J

118

R2

45

S

R1

Ø200

ØH

E363

C

945

F

D

ØA

ØB

Ø31

PANTONE Black

Offset 80g

58224_01 - Page 3/68