Platinum Access Systems ACTP715 User manual

Other Platinum Access Systems Gate Opener manuals

Platinum Access Systems

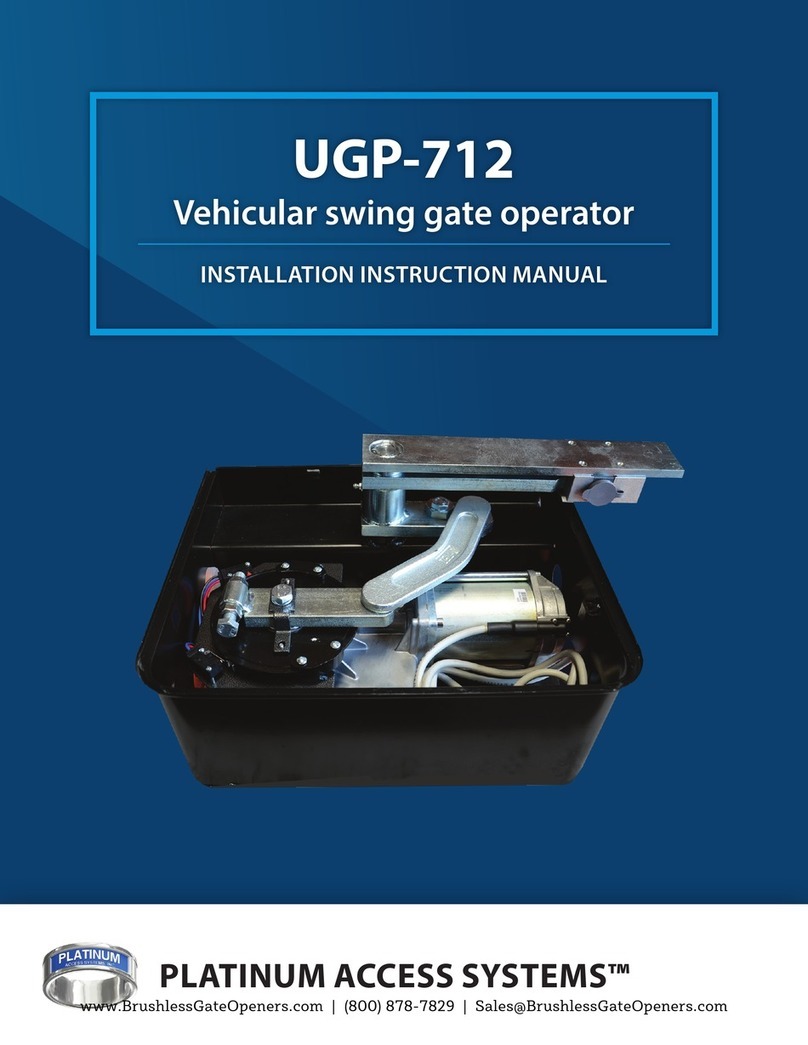

Platinum Access Systems UGP-712 Service manual

Platinum Access Systems

Platinum Access Systems BLSL3060 Quick start guide

Platinum Access Systems

Platinum Access Systems BLSW2212-B Service manual

Platinum Access Systems

Platinum Access Systems BLSW2212 User manual

Platinum Access Systems

Platinum Access Systems BLSL2250 Service manual

Platinum Access Systems

Platinum Access Systems BARRIER Service manual

Platinum Access Systems

Platinum Access Systems BLSW1016-B Service manual

Platinum Access Systems

Platinum Access Systems BLSL3060 Service manual

Platinum Access Systems

Platinum Access Systems BLSW1016 User manual

Popular Gate Opener manuals by other brands

Nortek Security & Control

Nortek Security & Control Mighty Mule HD272 installation manual

tousek

tousek TURN 10 Installation and operating instructions

SOMFY

SOMFY AXOVIA 220B RTS installation instructions

Nice HySecurity

Nice HySecurity CBOX1050 Installation and programming manual

CAME

CAME FROG-PM4 installation manual

Aprimatic

Aprimatic ONDA 500 installation instructions