Vector Control of an Induction Machine

1 Overview

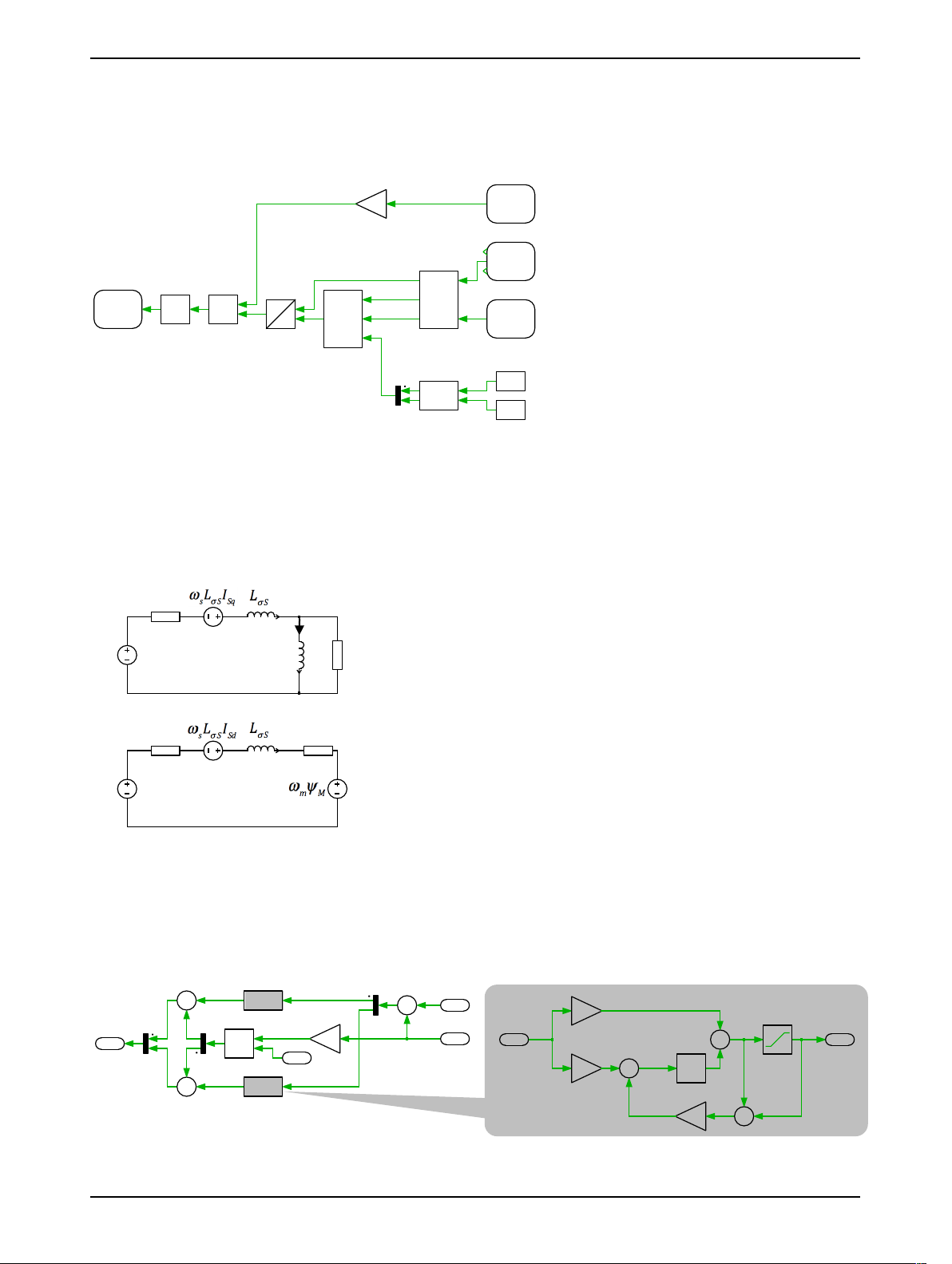

This demo model features an induction motor drive system with field oriented control. The drive is fed

by a DC voltage of 400 V and produces 200 Nm of torque. The model is split into two distinct subsys-

tems called “Plant” and “Controller”. The plant contains the drive system and the controller employs a

vector control scheme. These subsystems can then be independently built on the PLECS RT Box either

for Hardware-in-the-loop (HIL) testing of an external controller, or for rapid control prototyping (RCP).

The following sections provide a brief description of the model and instructions on how to simulate it.

Real-time execution on the RT Box requires the model to execute using a fixed-step solver. The dis-

cretization step size parameter specifies the base sample time of the generated code and is used to dis-

cretize the physical model and control domain state-space equations. The execution time represents

the actual time it takes to execute one discrete step of the PLECS model on the RT Box hardware. The

chosen discretization step sizes and average execution times for each subsystem in this demo model

are shown in Tab. 1.

Table 1: Discretization step size and average execution time of real-time models with two RT Box 1

Subsystem Discretization Step Size Average Execution Time

Plant 5 µs 2.4µs

Controller 100 µs(fsw = 10 kHz)2.8µs

1.1 Requirements

To run this demo model, the following items are needed (available at www.plexim.com):

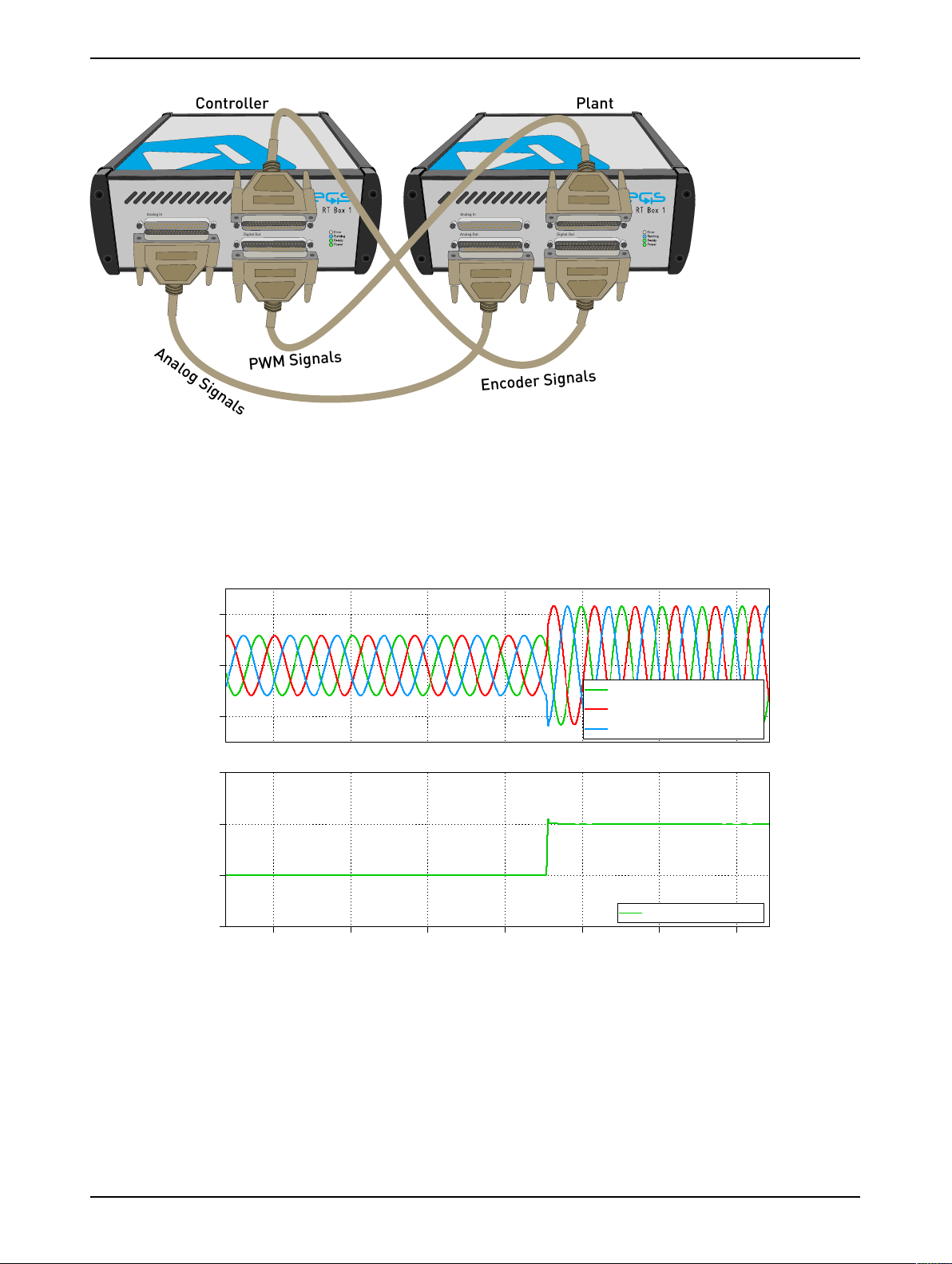

• Two PLECS RT Boxes and one PLECS and PLECS Coder license

• The RT Box Target Support Library

• Follow the step-by-step instructions on configuring PLECS and the RT Box in the Quick Start guide

of the RT Box User Manual.

• Three 37 pin Sub-D cables to connect the boxes front-to-front.

Note that this demo model is targeted at two RT Boxes application, with one running the Plant and

the other running the Controller. In this way, the execution time of each real-time target is minimized.

Besides, the setup can easily transition to a HIL or RCP test later on.

However if the user has only one RT Box available, please check the corresponding models targeted

for one RT Box application. In this case, two 37 pin Sub-D cables are still needed to connect in front

Analog Out interface with Analog In interface, and Digital Out interface with Digital In interface.

• For RT Box 2 and 3, by default the multi-tasking feature is enabled in this demo. “Controller” part

is circled with a Task frame block, and runs in one core. The rest of the circuit on the schematic be-

longs to the “Base task”, and runs in another core. In this way the computational effort is split onto

different cores. Please check the default setting under Scheduling tab of the Coder options... win-

dow.

• For RT Box 1, multi-tasking is disabled since there is only one CPU core available for calculating

the model, which includes both Plant and the Controller.

Note This model contains model initialization commands that are accessible from:

PLECS Standalone: The menu Simulation + Simulation Parameters... + Initializations

PLECS Blockset: Right click in the Simulink model window + Model Properties + Callbacks +

InitFcn*

www.plexim.com 1