0000117916/221118/A Balancer-200 and -300 series EN - 4

2 PRODUCT DESCRIPTION

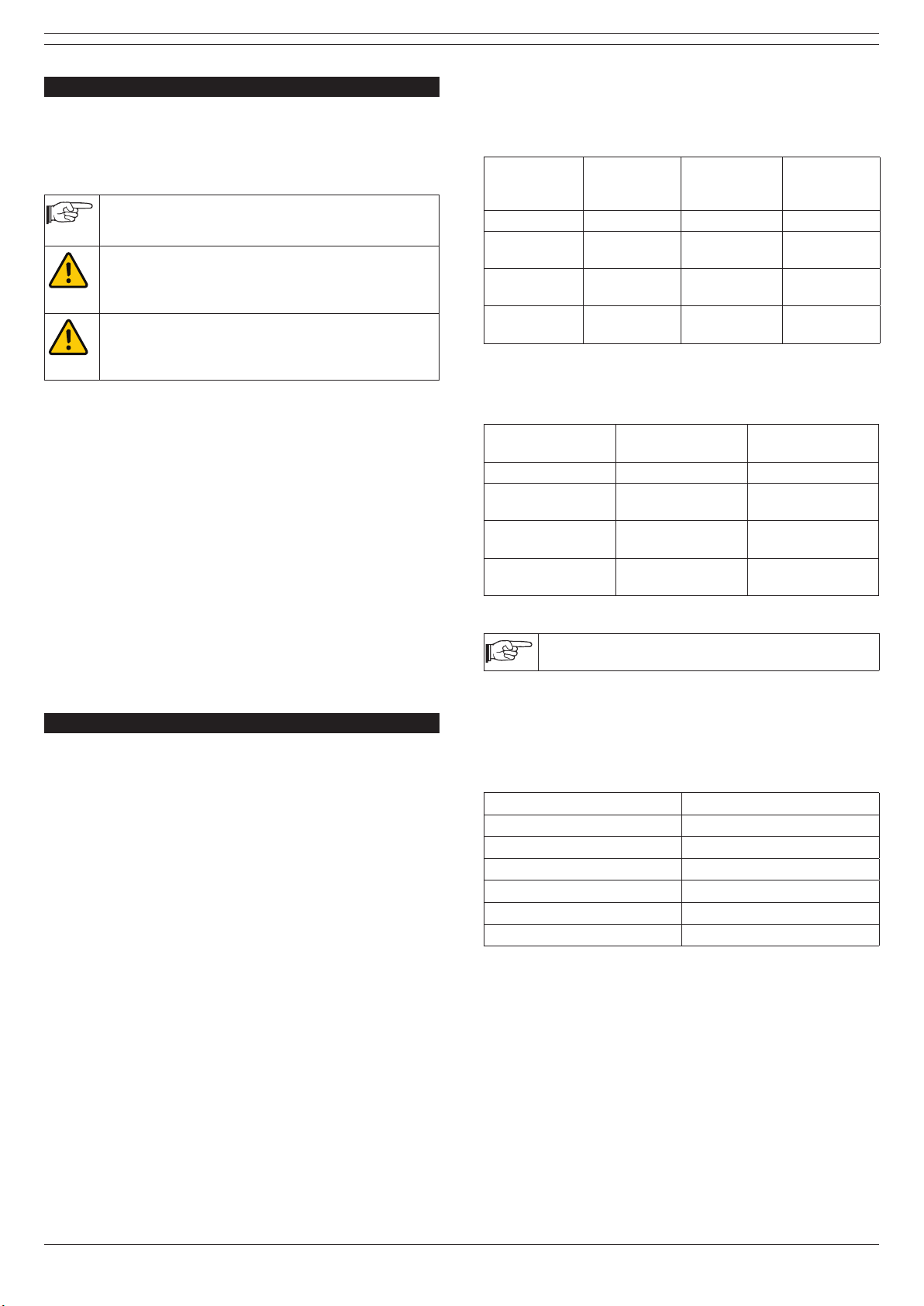

2.1 Product components

The product consists of the following main components and

elements:

Fig. 2.1

A re brigade snap hook Ø 8 mm (5/16 in.)

B spring tension lock

C balancer locking cable (optional)

D balancer wire stop

E wire

F re brigade snap hook Ø 8 mm (5/16 in.)

G safety wire

H balancer body including spring

Fig. 2.1 Main components

3 SAFETY INSTRUCTIONS

General

The manufacturer does not accept any liability for damage to

the product or personal injury caused by ignoring of the safety

instructions in this manual, or by negligence during installation,

use, maintenance, and repair of the product mentioned on the

cover of this document and any corresponding accessories.

Specic working conditions or used accessories may require

additional safety instructions. Immediately contact your supplier

if you detect a potential danger when using the product.

The user of the product is always fully responsible for

observing the local safety instructions and regulations.

Observe all applicable safety instructions and regulations.

User manual

- Everyone working on or with the product, must be familiar

with the contents of this manual and must strictly observe

the instructions therein. The management should instruct the

personnel in accordance with the manual and observe all

instructions and directions given.

- Do not change the order of the steps to perform.

- Keep the manual with the product.

Users

- The use of this product is exclusively reserved to authorised,

trained and qualied users. Temporary personnel and

personnel in training can only use the product under

supervision and responsibility of skilled engineers.

- Stay alert and keep your attention to your work. Do not use

the product when you are under the inuence of drugs,

alcohol or medicine.

- The product is not to be used by children or persons with

reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given

supervision or instruction.

- Children must be supervised not to play with the product.

Technical specications

Do not change the specications given in this manual.

Modications

Modication of (parts of) the product is not allowed.

Installation

- The installation of this product is exclusively reserved to

authorised, trained and qualied engineers.

- During installation, always use Personal Protective

Equipment (PPE) to avoid injury. This also applies to persons

who enter the work area during installation.

- Use sucient climbing gear and safety guards when working

on a higher level than 2 metres (6 ft. OSHA) (local restrictions

may

apply).

- Do not install the product in front of entrances and exits

which must be used for emergency services.

- Mind any gas and water pipes and electric cables.

- Make sure that the workspace is well illuminated.

- Stay alert and keep your attention to your work. Do not

install the product when you are under the inuence of

drugs, alcohol or medicine.

Use

- Inspect the product and check it for damage. Verify the

functioning of the safety features.

- Check the working environment. Do not allow unauthorised

persons to enter the working environment.

- Protect the product against water and humidity.

- Make sure the room is always suciently ventilated; this

applies especially to conned spaces.

- Make sure that the workshop, in the vicinity of the product,

contains sucient approved re extinguishers (suitable for

re classes ABC).

Service, maintenance and repairs

- Obey the maintenance intervals given in this manual.

Overdue maintenance can lead to high costs for repair and

revisions and can render the guarantee null and void.

- Always use Personal Protective Equipment (PPE) to avoid

injury. This also applies for persons who enter the work area.

- Make sure the room is suciently ventilated.

- Use tools, materials, lubricants and service techniques which

have been approved by the manufacturer. Never use worn

tools and do not leave any tools in or on the product.

- Use sucient climbing gear and safety guards when working

on a higher level than 2 metres (6 ft. OSHA) (local

restrictions may apply).

- Clean the area afterwards.