0000110982/231018/A SER EN - 4

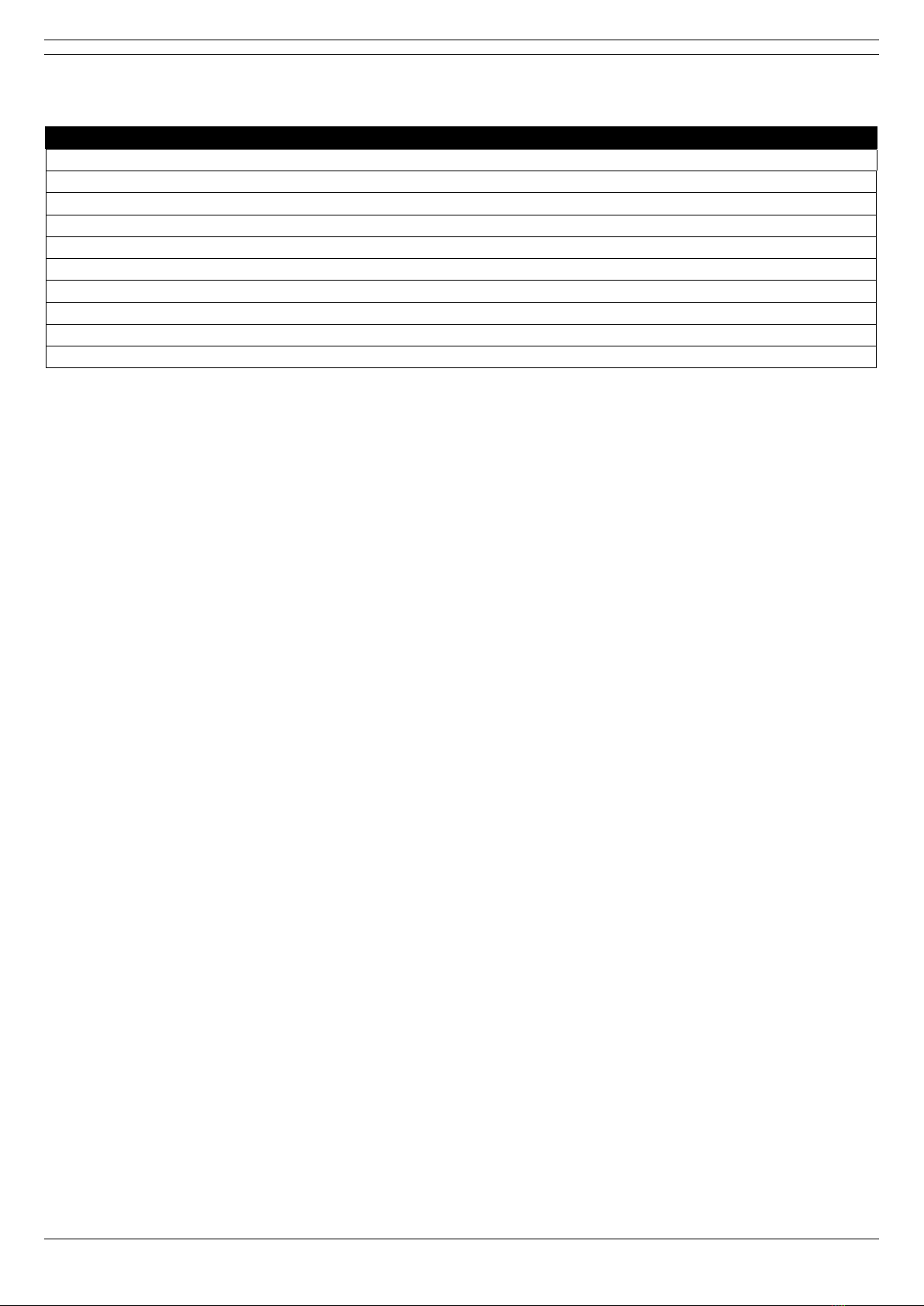

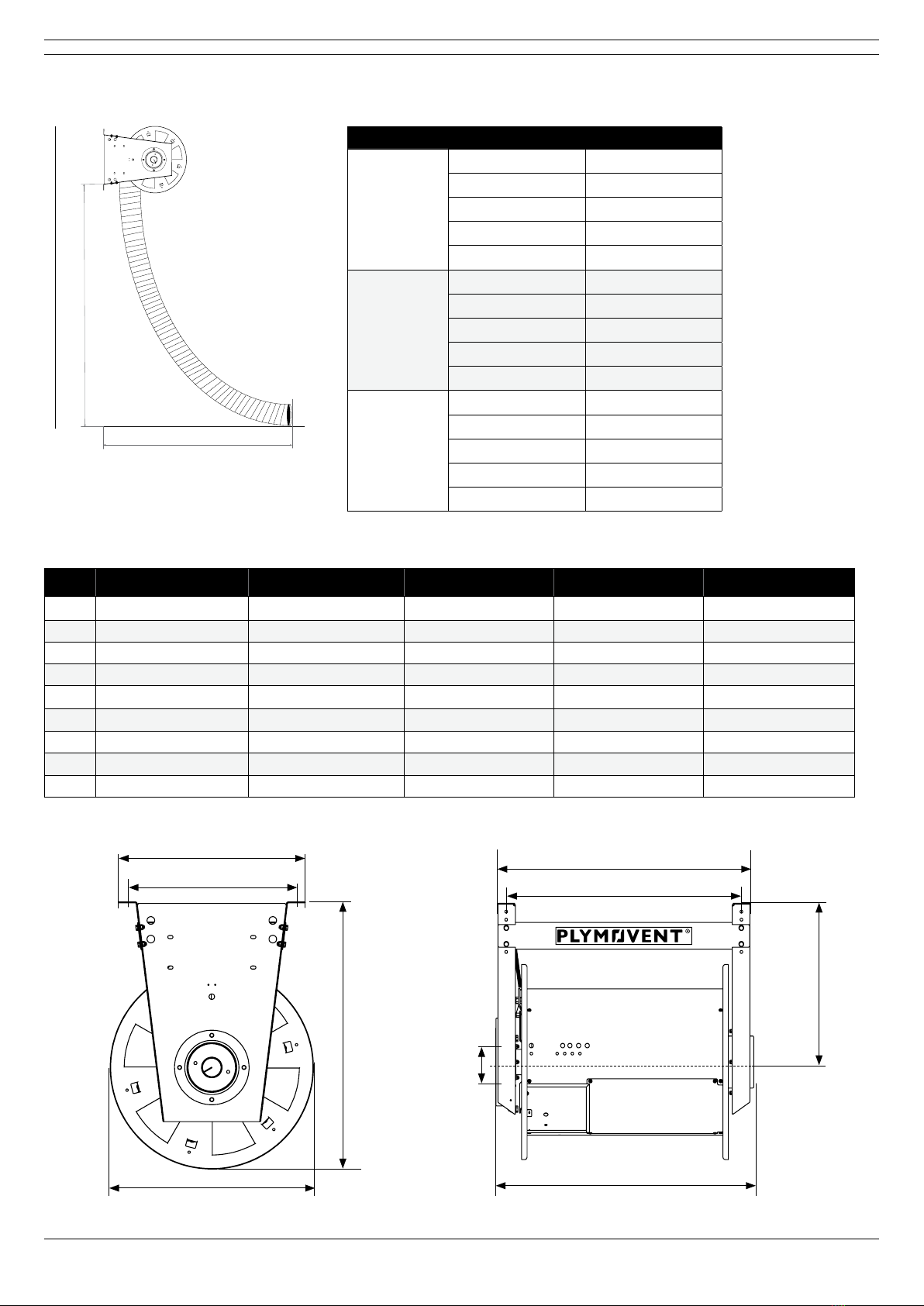

1.4.1 Maximum hose length

The maximum hose length that SER supports is dependent on

these factors:

- the specic version of SER hose reel ordered;

- the type and size of the hose;

- the nozzle;

For example, a 125 mm (5 in.) standard hose can be wrapped

around the drum for a maximum of ve rotations, which would

equal 8,2 m (27 ft). The table below demonstrates the total

weight of the Plymovent EF hose, REGD nozzle and rubber

hose stop. Each system’s total weight will vary.

Component Weight

calculation Total weight

125 mm hose 1,09 kg/m

(0.7 lbs/ft) 8,9 kg (19,6 lbs)

Rubber nozzle

REGD-150-160 2 kg (4.4 lbs) 2 kg (4.4 lbs)

Rubber hose stop 2,7 kg (6 lbs) 2,7 kg (6 lbs)

Total weight of hose and components: 13,6 kg (27 lbs)

SER lifting capacity (single cassette): 18,2 kg (40 lbs)

1.4.2 Weight of SER Unit without components

Product Hose

diameter

Maximum

hose length

on reel

Weight

without

components

SER-45 0 -75 Ø 75 mm (3 in.) 7,5 m (24.6 ft) 44 kg (97 lbs)

SE R- 450 -10 0 Ø 100 mm (4 in.) 6 m (19.7 ft) 44 kg (97 lbs)

SER-650-100* Ø 100 mm (4 in.) 10 m (33 ft) 49 kg (108 lbs)

SER-650-125* Ø 125 mm (5 in.) 7,5 m (25 ft) 49 kg (108 lbs)

SER-850-100 Ø 100 mm (4 in.) 10 m (33 ft) 54 kg (119 lbs)

SER-850-125 Ø 125 mm (5 in.) 10 m (33 ft) 54 kg (119 lbs)

SER-850-150 Ø 150 mm (6 in.) 10 m (33 ft) 54 kg (119 lbs)

SER-1050-100 Ø 100 mm (4 in.) 12,5 m (41 ft) 56 kg (123 lbs)

SER-1050-125 Ø 125 mm (5 in.) 12,5 m (41 ft) 56 kg (123 lbs)

SER-1050-150 Ø 150 mm (6 in.) 12,5 m (41 ft) 56 kg (123 lbs)

SER-1050-200 Ø 200 mm (8 in.) 10 m (33 ft) 56 kg (123 lbs)

If a second spring cassette is included, add 7,7 kg

(17 lbs) to the product weight.

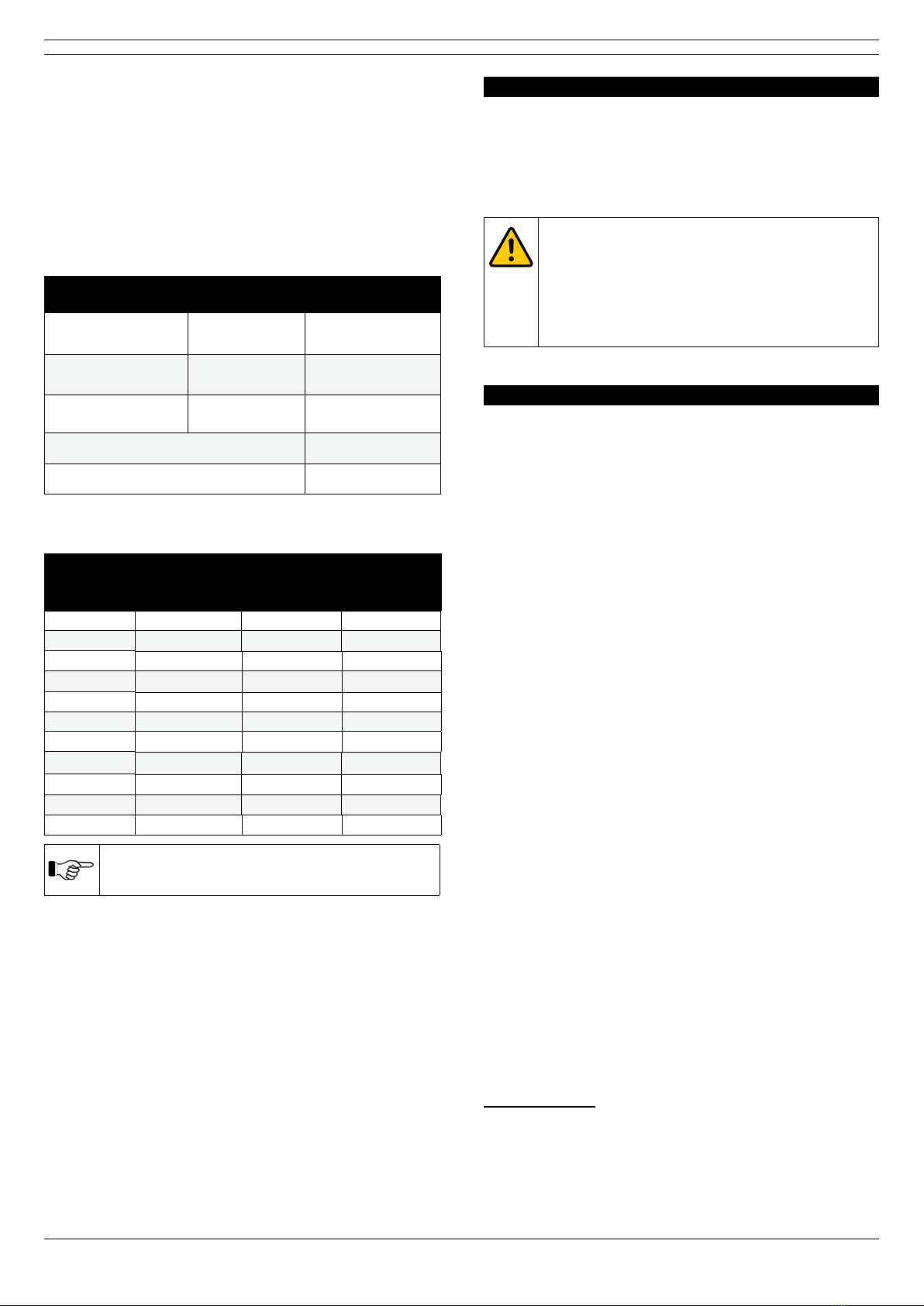

1.5 Dimensions

Refer to section 4.2 and 4.3 for dimensions and weights.

1.6 Transport of the unit

The manufacturer cannot be held liable for any transportation

damage after shipment of the unit. Always handle the unit and

the accompanying options and/or accessories, if any, with

care.

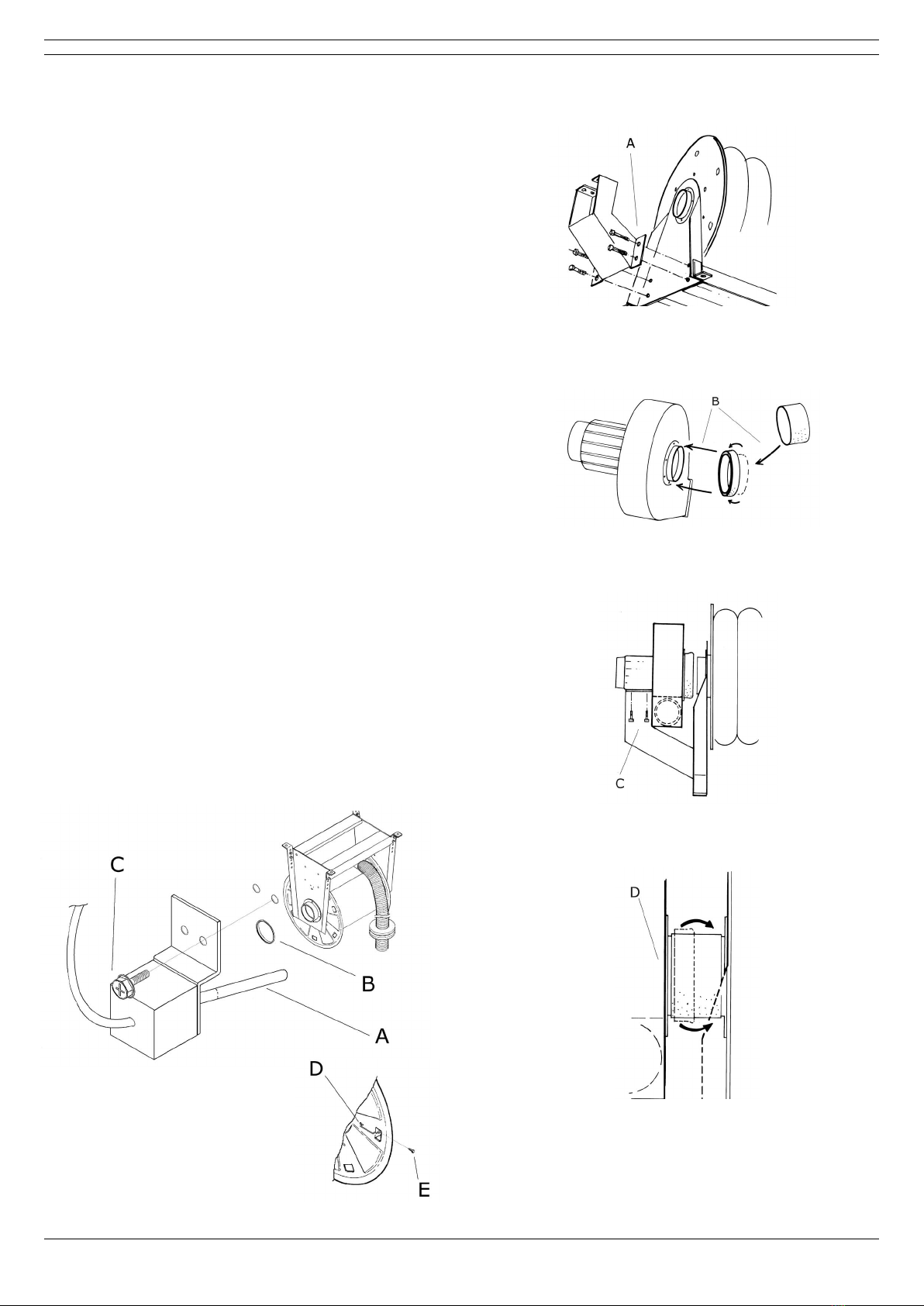

The hose reel is bolted on a skid and delivered with a ceiling or

wall mounting bracket. Based on SER being ordered, the duct

connection includes either a Ø 165 mm (6.5 in.) with reducer

to 160 mm (6 in.) or a Ø 200 mm (8 in.) duct connection

collar.

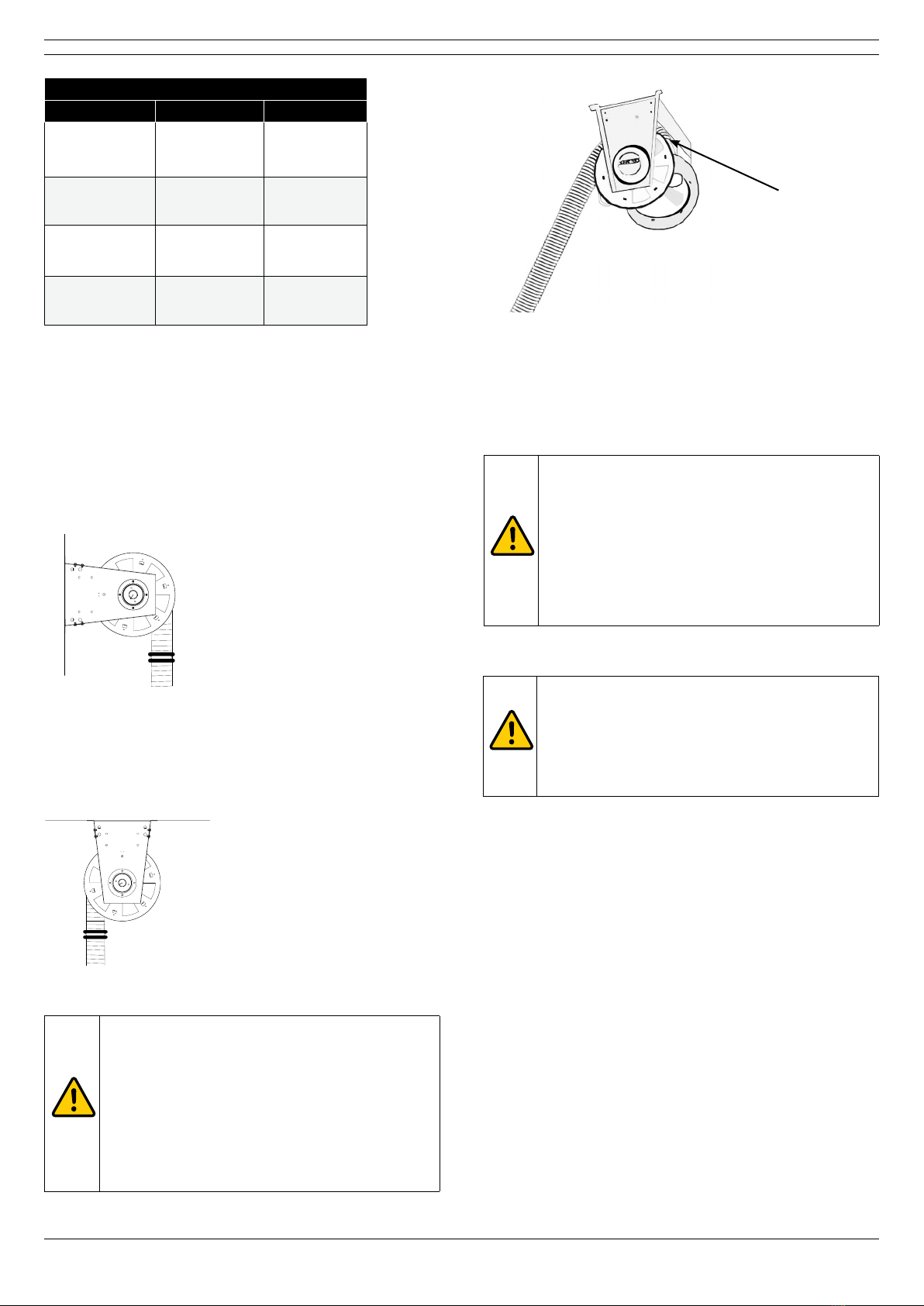

2 PRODUCT DESCRIPTION

2.1 Operation

SER works according to the “blind” principle. The operator

pulls the hose to lock it into the required position and pulls a

second time to recoil the hose on the reel. The hose stopper is

set to the required height when returning the hose to the reel.

WARNING!

The sealed spring cassette contains a powerful

spring and must not be opened. Be careful when

servicing the SER product. If you have any

questions about the content in this manual, please

contact Plymovent or your Plymovent authorised

distributor. Be careful when operating the hose reel

so as to avoid damage to persons and property.

3 SAFETY INSTRUCTIONS

General

The manufacturer does not accept any liability for damage to

the product or personal injury caused by ignoring the safety

instructions in this manual, or by negligence during

installation, use, maintenance, and repair of the product

mentioned on the cover of this document and any

corresponding accessories. Specic working conditions or used

accessories may require additional safety instructions.

Immediately contact your supplier if you detect a potential

danger when using the product.

The user of the product is always fully responsible for

observing the local safety instructions and regulations.

User manual

- Everyone working on or with the product must be familiar

with the contents of this manual and must strictly observe

the instructions therein. The management should instruct the

personnel in accordance with the manual and observe all

instructions and directions given.

- Never change the order of the steps to perform.

- Always keep the manual with the product.

Pictograms and instructions on the product (if

present)

- The pictograms, warning and instructions attached to the

product are part of the safety features. They must not be

covered or removed and must be present and legible during

the entire life of the product.

- Immediately replace or repair damaged or illegible

pictograms, warnings and instructions.

Users

The use of this product is exclusively reserved to authorised,

trained and qualied users. Temporary personnel and

personnel in training can only use the product under

supervision and responsibility of skilled engineers.

Intended use1

The product has been designed to extract exhaust gases.

Using the product for other purposes is considered contrary to

its intended use. The manufacturer accepts no liability for any

damages or injury resulting from such use. The product has

1 “Intended use” as explained in EN-ISO 12100 is the use for which the technical

product is suited as specied by the manufacturer, inclusive of his directions in

the sales brochure. In case of doubt it is the use which can be deduced from

the construction, the model and the function of the technical product which is

considered normal use. Operating the machine within the limits of its intended

use also involves observing the instructions in the user manual.

*650 models are not available in USA and Canada.