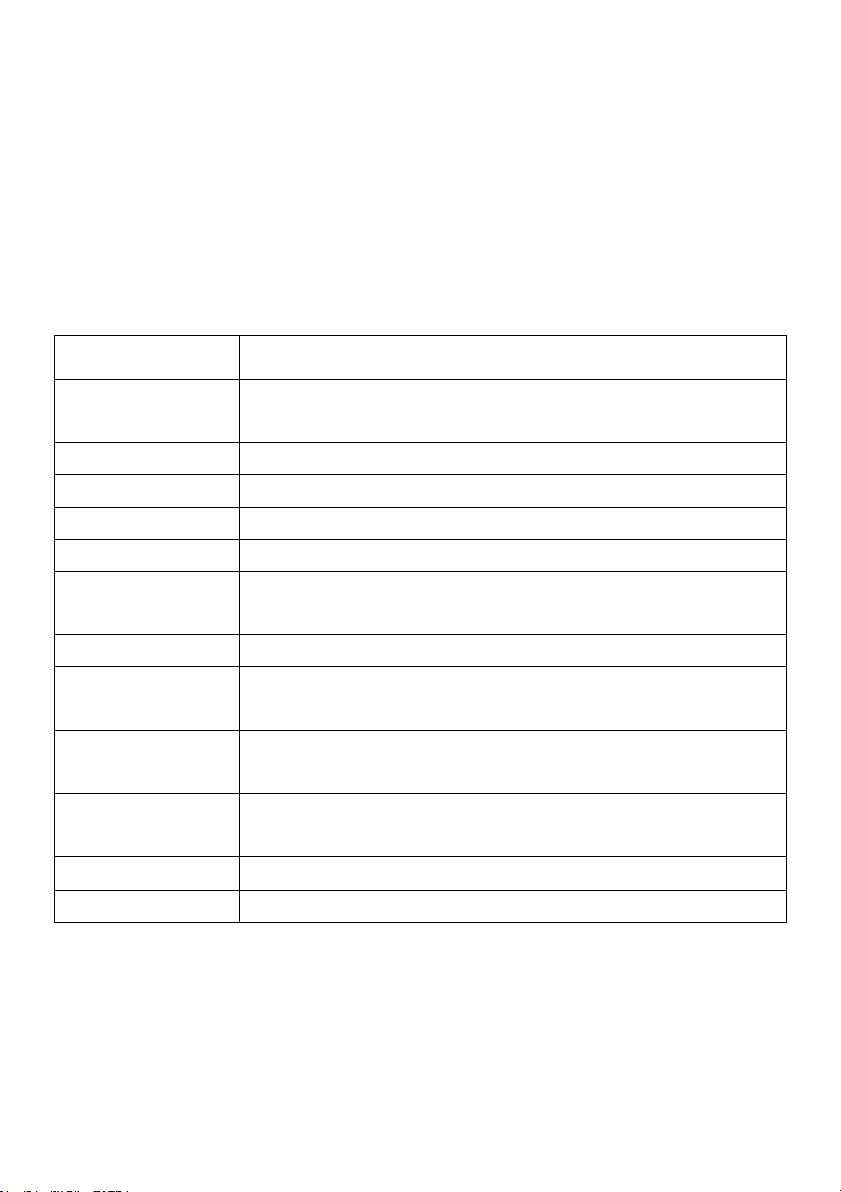

Step 2: Open the door (permissible speed 1 to 10 gears, see

Chapter3 ).

Step 3 : Open & slow down(permissible speed 1 to 9 gears, see

Chapter 3 ).

Step 4: Stop it.

Step 5: Open &hold (permissible time 1 to 99 seconds, see

Chapter3).

Step6: Close the door (permissible speed 1 to 9 gears, see Chapter

3 ).

Step7: Close & slow down(permissible speed 1 to 9 gears, see

Chapter 3)

Step8: Electromagnetic lock power on.

Step9: Press door closed.

End of a work flow.

Note: In the process of closing the door, if there is a trigger signal for

opening the door, the action of opening the door will be executed

immediately.

1.2 Product Characteristics

1). Low consumption, static power :0.5W, maximum power: 25W.

2). Super silence, working noise less than 50 dB.

3). Small size, easy installation.

4). Powerful, maximum push door weight 140 Kg.

5). Support multiple signal input, relay signal, voltage signal (5-24V).

6). motor over-current, overload, short-circuit protection.