User manual 10

English

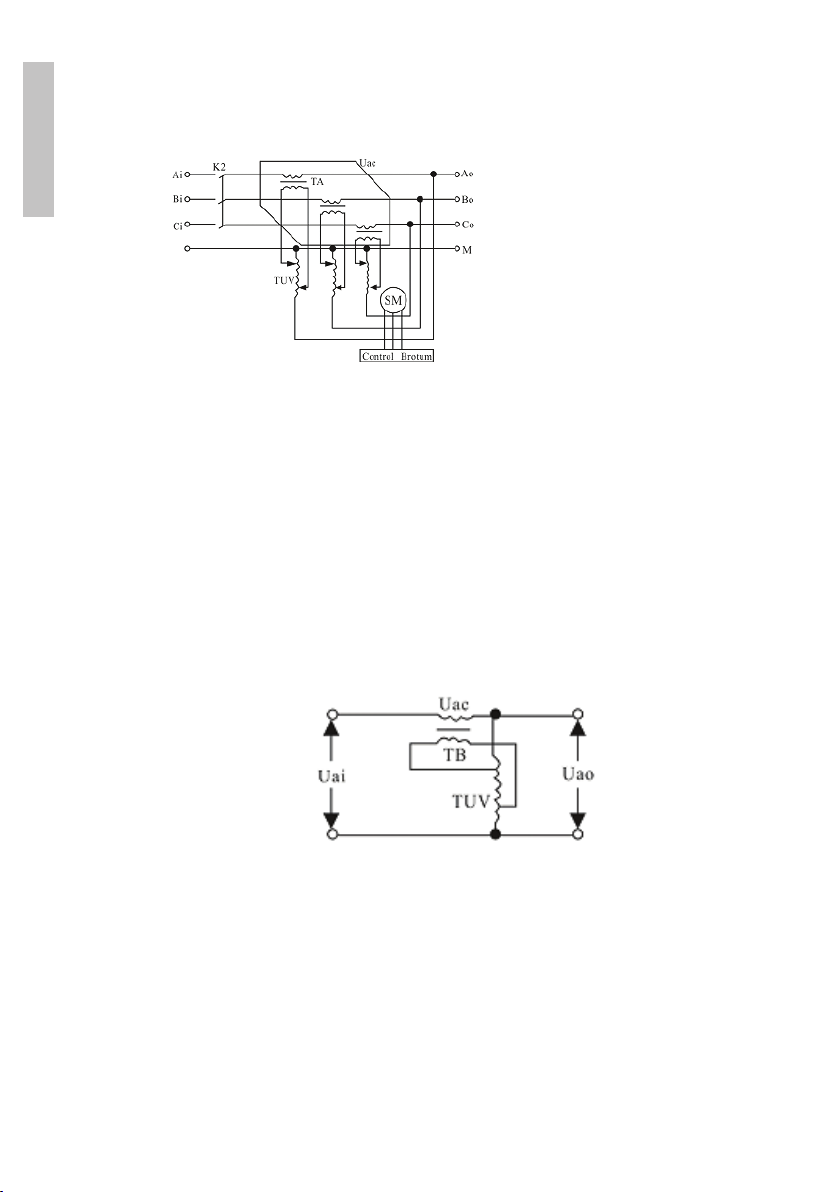

so as to ensure the reliable operation of the voltage stabilizer. The details are

as follows:

• Check the main loop connection wire to see if it is properly connected

and if the universal switch connection wires are in position. Tighten well if

it gets weak.

• Check the contact wires of all types of electrical devices behind the panel,

such as the voltmeter, ammeter, switch and see if they are connected

correctly. Tighten well if they get weak.

• Check the circuit board to see if the connecting wires of each point are

connected correctly. You should tighten them if they are loose.

• Check the servomotor on the voltage regulator and see if the connection

wire of the limit switch is in order. You should tighten it if it is weak.

• Check the control circuit board and power switch C45, which controls the

power supply to the electric motor in the control box, and see if they are

closed.

Electrical operation and troubleshooting

1. Move the “Manual/Automatic” switch to the “Manual” position.

2. Move the knife switch to the “Voltage Stabilization” position; the voltage

of the stabilizer is in the state of zero load.

3. Turn on the power supply, close the QA switch, and at this moment, the

light indicator of the three-phase power source on the panel will light up.

The input voltage is displayed.

4. Press the “Voltage Stabilization” button, and after 5-15 seconds, the delay

relay will be closed, which causes the output contactor to be electrified

and closed. The green light for “Voltage Stabilization” is on. Then, press

the “Voltage Step-up” or “Voltage Step-down” button, and the output

voltmeter indicator will increase or decrease accordingly; thus completing

the manual voltage adjustment test.

Note:

If the voltage stabilizer cannot start and the indicator LEDs of the phase

sequence protector are not lit after pressing the “Voltage stabilization” button,

it means that the phase sequence is connected incorrectly. To fix this problem,

you must first turn o the power supply and then change either of the two

wires.

After pressing the “Voltage stabilization” button, the voltage stabilizer will have