POK AQUASTAR User manual

AQUASTAR

High pressure hand nozzle with selectable flow rate

and stream pattern, 180 lpm, spinning teeth

POK SAS - ZI Les Guignons - 10400 Nogent-sur-Seine - FRANCE

MOP_LAM_01403_EN_A - 24/02/2017

User manual

POK SAS - ZI Les Guignons - 10400 Nogent-sur-Seine - FRANCE

MOP_LAM_01403_EN_A - 24/02/2017 - Copyright© POK SAS - Illustrations are only informative

2

AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth

Identication

DESIGNATION DESCRIPTION

Product type Hand nozzle

Product AQUASTAR, high pressure hand nozzle with selectable

ow rate and stream pattern, 180 lpm, spinning teeth

Product reference concerned by the manual Ref: 39585

N° of documentation MOP_LAM_01403_EN_A

Language English

Creation Date 22/02/2017

Last modication -

Review follow up Rev. A - 22/02/2017:

Original le

POK SAS - ZI Les Guignons - 10400 Nogent-sur-Seine - FRANCE

Tel: +33 (0)3 25 39 84 78 - Fax: +33 (0)3 25 39 84 90 - Email: [email protected] - Web: www.pok.fr 3

MOP_LAM_01403_EN_A - 24/02/2017 - Copyright© POK SAS - Illustrations are only informative

AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth

Table of contents

IDENTIFICATION .......................................................................................................2

TABLE OF CONTENTS .................................................................................................3

WARNING ..................................................................................................................4

• Note .............................................................................................................4

• General Warning.............................................................................................4

• Security ........................................................................................................4

• Introduction...................................................................................................4

• Dismantling and Warranty................................................................................4

• Use ..............................................................................................................5

• Limits of use ..................................................................................................5

TECHNICAL DATA.......................................................................................................6

MAIN VIEW ..........................................................................................................6

OVERALL DIMENSIONS..........................................................................................7

CHARACTERISTICS ...............................................................................................8

• Construction ..................................................................................................8

• Hydraulic Characteristics .................................................................................8

• Mechanical Characteristics ...............................................................................8

1 - General data ...............................................................................................9

2 - Flow chart / pressure curve ...........................................................................9

3 - Mechanical System.......................................................................................9

4 - Prescriptions ............................................................................................. 10

5 - Certied by: ............................................................................................. 10

INSTRUCTIONS FOR USE ......................................................................................... 11

CONTROL AND OPERATING .................................................................................. 11

• Before applying pressure ............................................................................... 11

• Openning .................................................................................................... 11

• Adjusting the ow rate and ush .................................................................... 11

• Jet adjustment ............................................................................................. 11

MAINTENANCE......................................................................................................... 12

• assembly/disassembly................................................................................... 12

• Cleaning...................................................................................................... 13

• Spare parts..................................................................................................13

• Handling / Transport / Storage ....................................................................... 13

BILL OF MATERIALS ................................................................................................ 14

EXPLODED VIEW................................................................................................. 14

PARTS LIST ........................................................................................................ 15

NOTES ..................................................................................................................... 16

POK SAS - ZI Les Guignons - 10400 Nogent-sur-Seine - FRANCE

MOP_LAM_01403_EN_A - 24/02/2017 - Copyright© POK SAS - Illustrations are only informative

4

AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth

Warning

• Note

POK SAS reserves the right to change or modify the specications of its products at any time to incorporate

the latest technological and regulatory developments. The information contained in this document is subject

to change without notice.

• General Warning

Before using or installing the equipment, it is essential for the safety of people and

equipment, to read the information contained in this operating manual before using

the equipment. The use, maintenance, or any other operation of the equipment,

must be carried out exclusively by personnel informed of safety rules and trained in

the use of this material.

The non-compliance of safety instructions can be dangerous and cause serious

bodily harm and/or property damage.

• Security

This symbol indicates important safety tips. Pay careful attention to prevent serious bodily

harm and/or property damage.

This symbol indicates instructions that must be observed to ensure smooth operation of the

device. Please always make sure to follow all the necessary precautions.

This symbol indicates useful information to know and understand the correct operation of the

device.

• Introduction

Please read the information contained in this manual before using or operating the equipment.

The use, maintenance or any other operation of the equipment, must be carried out exclusively by personnel

informed of safety rules and trained in the use of the equipment.

While using the re nozzle (use, maintenance, installation, ...) it is important to wear personal protective

equipment.

• Dismantling and Warranty

This product is guaranteed for a period of one years for any manufacturing defect, except with special

written agreement.

The exploded views and parts lists are not a dismantling manual.

Any dismantling or maintenance operation of the device must be done with the water supply turned off.

Dismantling and/or modication of the equipment outside POK SAS factory is allowed only in compliance

with procedures described in this manual, and therefore does not affect the warranty.

POK SAS - ZI Les Guignons - 10400 Nogent-sur-Seine - FRANCE

Tel: +33 (0)3 25 39 84 78 - Fax: +33 (0)3 25 39 84 90 - Email: [email protected] - Web: www.pok.fr 5

MOP_LAM_01403_EN_A - 24/02/2017 - Copyright© POK SAS - Illustrations are only informative

AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth

Warning

If the equipment is repaired, the spare parts must be supplied by POK SAS. Otherwise, the technical

specications in this document will no longer be valid, the warranty will be invalid and the manufacturer’s

responsibility will no longer be committed.

If a maintenance operation leads to a deterioration of parts, the guarantee may not be applicable if the

procedure is not carried out in accordance with this manual.

Although it is not explicitly stated in instructions, use and wear of protective equipment are obligatory during

maintenance operations. POK SAS cannot be responsible for any damage or accident which may occur during

the dismantling. If this obligation is not met, please refer to the tools instructions guides for more details.

Only POK is able to guarantee proper functioning and security of the equipment following a disassembly.

Accordingly, POK SAS cannot be held liable for any incidents caused as a result of the dismantling outside

of its workshops.

Do not modify the equipment, it may not work properly or be dangerous for use. Any modication not

approved by POK SAS will void the warranty.

• Use

Please respect the technical limitations of the equipment.

The equipment should not be used if a component is damaged or missing.

Disrespect of safety instructions and use of the branchpipe over the recommended pressure

can be dangerous and even cause death.

It is important to know and respect the safety rules regarding your operating environment.

In case of re that occurs near or caused by electrical installations, it is imperative to:

1) Cut of power supply as soon as possible

2) Maintain a safe distance of at least 1 meter up to 1,000 bolts.

3) To use a spray with a minimum 30° angle.

Before placing the nozzle in service, check :

1) No part is damaged, broken or missing.

2) that the coupling is perfectly connected to the hose.

3) that the swivel tting freely.

4) the opening and closing of the valve.

5) That the ush ring works properly

6) That the ow pattern selector rotates and slides properly.

POK SAS is not responsible of any accident that may occur during operation caused by improper use or non-

compliance with safety requirements.

• Limits of use

Our nozzles are guaranteed for a maximum operating pressure of PN 40.

Our nozzles are guaranteed to resist a maximum of 60 bar in a closed position.

Without explicit written authorization from POK, the warranty will be void if the pressures

listed above are exceeded.

POK SAS - ZI Les Guignons - 10400 Nogent-sur-Seine - FRANCE

MOP_LAM_01403_EN_A - 24/02/2017 - Copyright© POK SAS - Illustrations are only informative

6

AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth

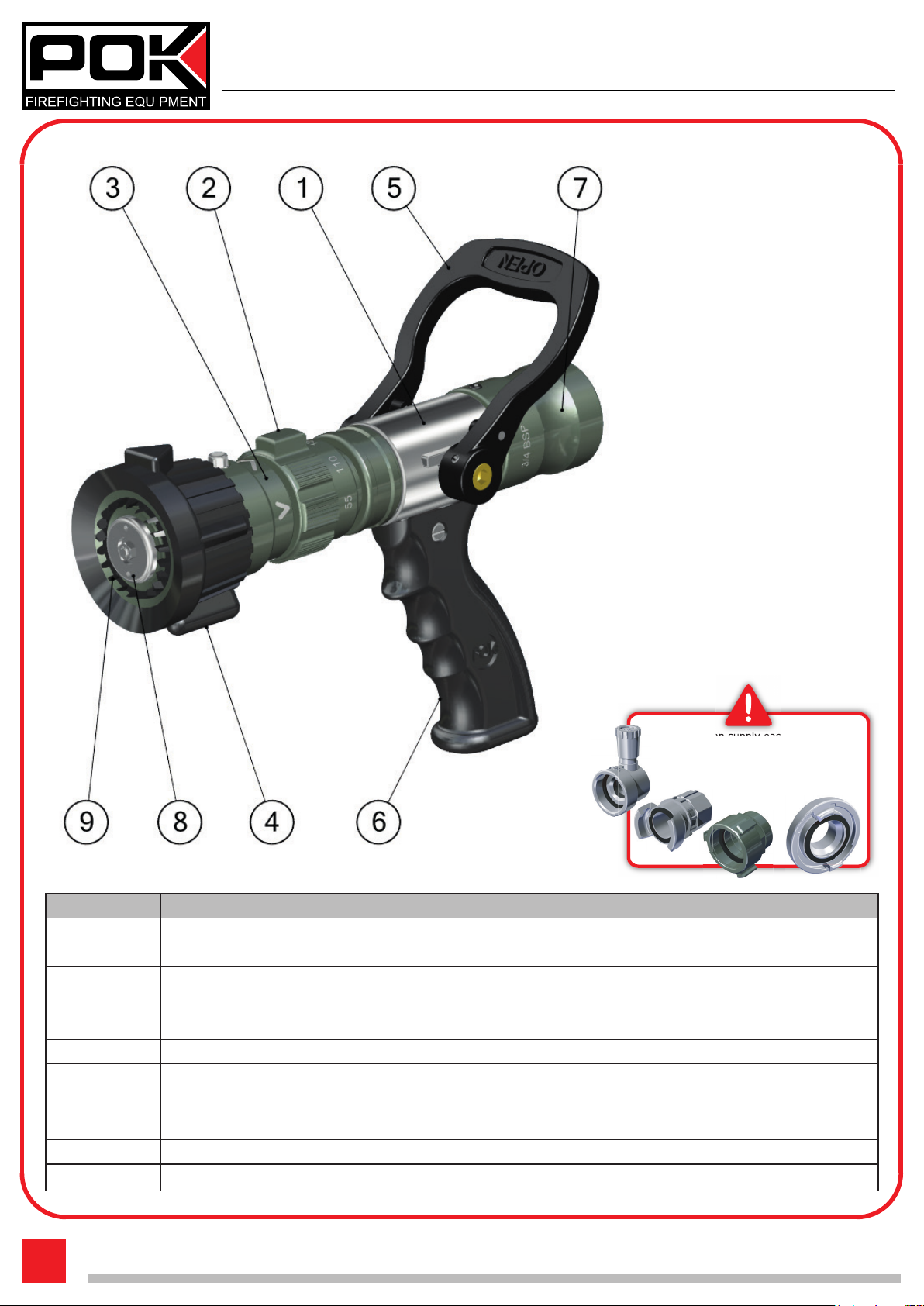

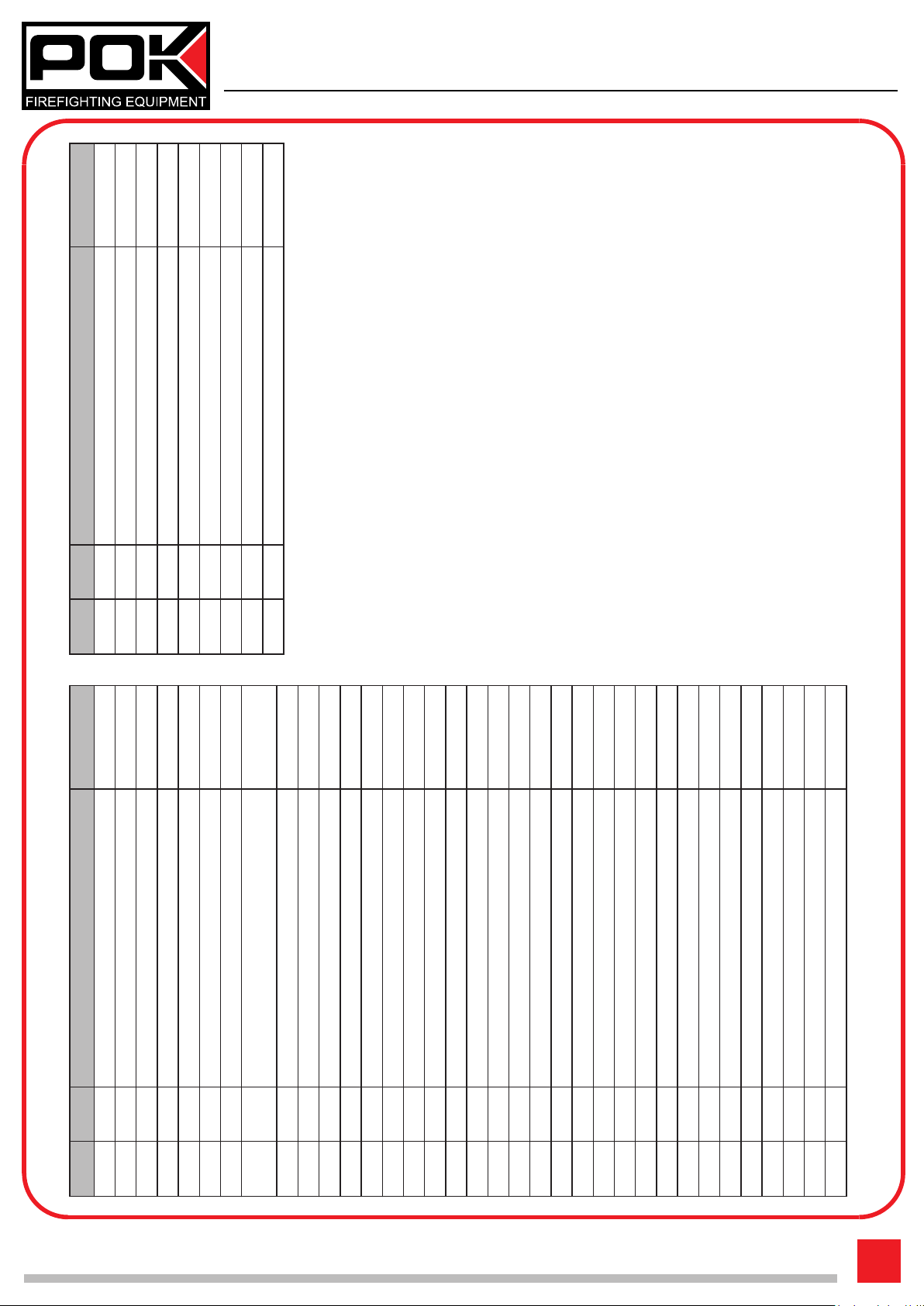

Main view

Technical data

MARK DESCRIPTION

1 Body

2 Flow rate adjustment ring

3 Stream pattern adjustment ring

4 Head bumper with tactile indicators for stream pattern

5 Shutoff handle

6 Pistol handle with polyurethane cover

7

Swivel inlet 3/4’’ BSP female thread

Note: A different coupling is available upon request. See our catalogue for more information on

couplings.

8 Stem

9 Spinning teeth

POK SAS can supply each product with

different couplings. Depending on your

order the couplings can be different

from the ones shown here.

can supply each product with

POK SAS - ZI Les Guignons - 10400 Nogent-sur-Seine - FRANCE

Tel: +33 (0)3 25 39 84 78 - Fax: +33 (0)3 25 39 84 90 - Email: [email protected] - Web: www.pok.fr 7

MOP_LAM_01403_EN_A - 24/02/2017 - Copyright© POK SAS - Illustrations are only informative

AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth

AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth

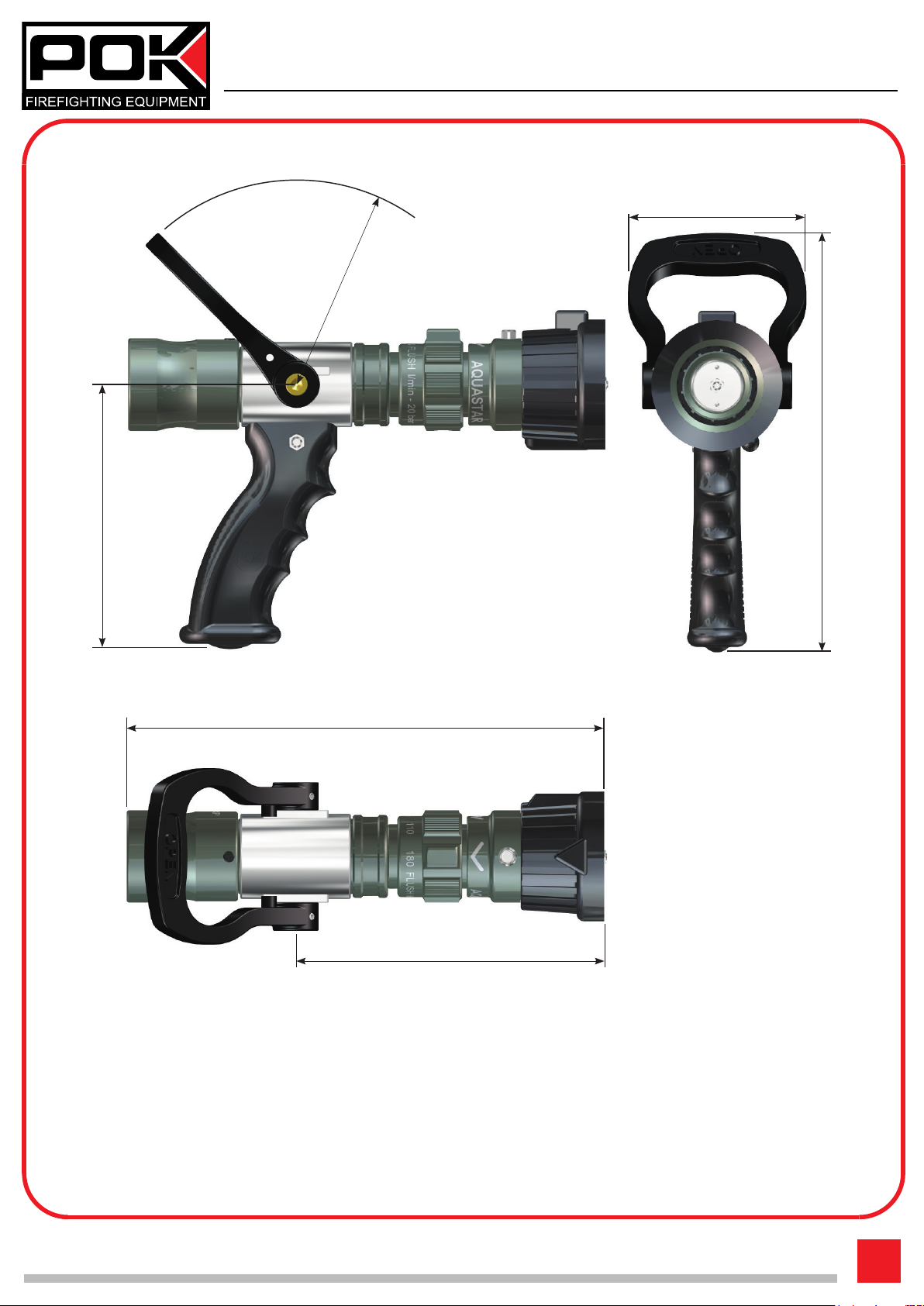

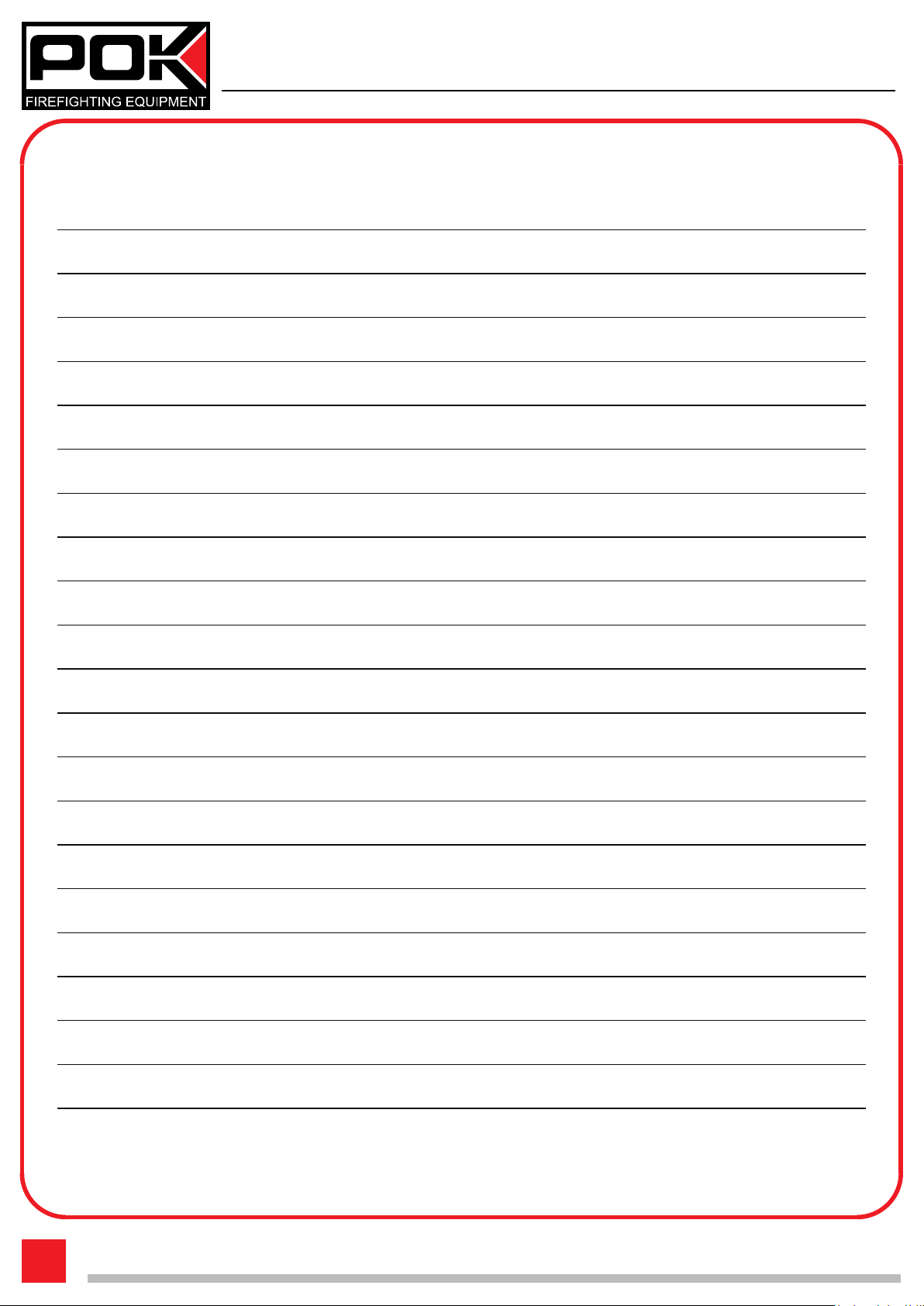

Overall dimensions

Technical data

Weight: 1,62 Kg

224 mm

R 111 mm

143 mm

95 mm

260 mm

167 mm

POK SAS - ZI Les Guignons - 10400 Nogent-sur-Seine - FRANCE

MOP_LAM_01403_EN_A - 24/02/2017 - Copyright© POK SAS - Illustrations are only informative

8

AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth

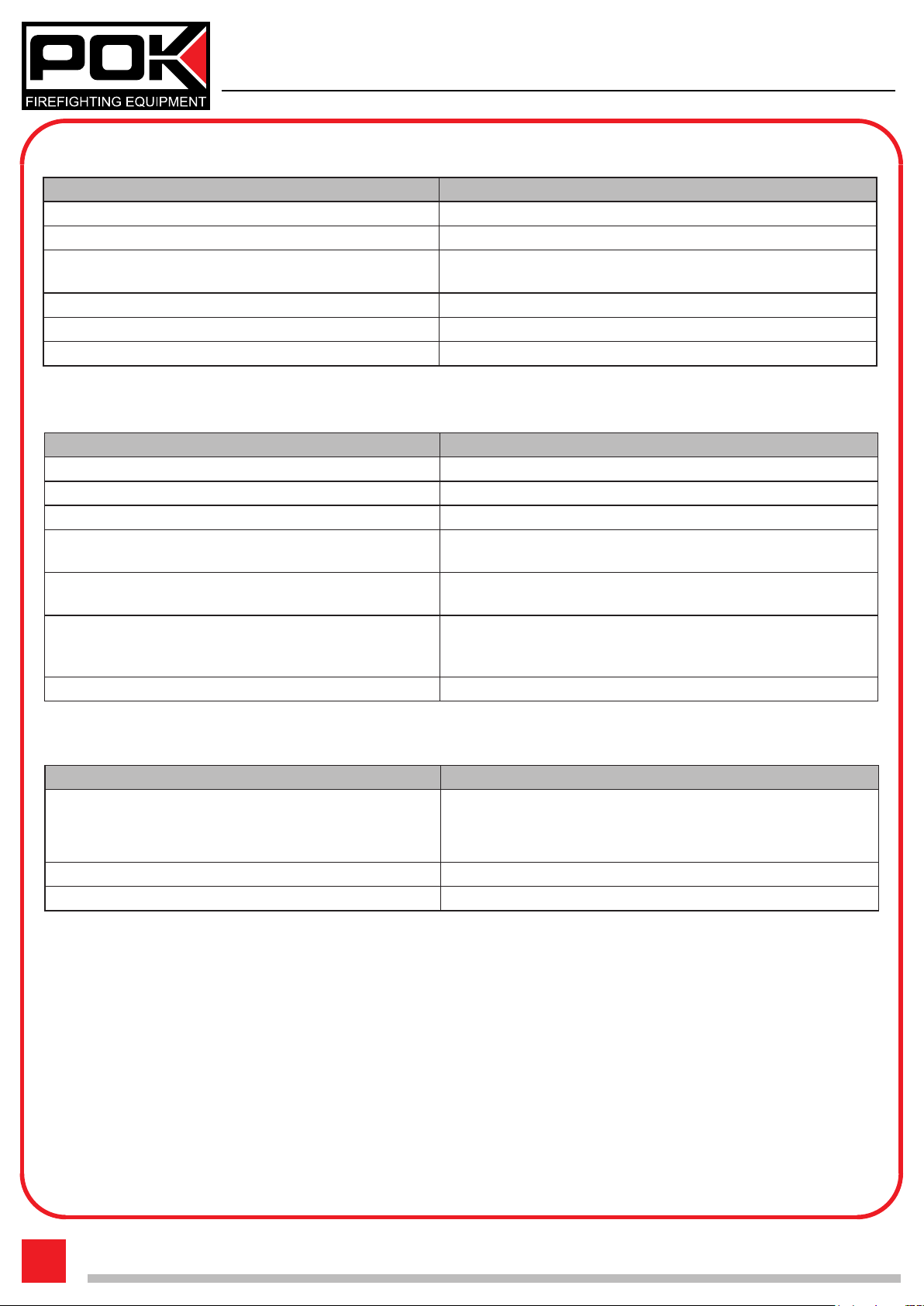

Characteristics

Technical data

DESIGNATION DESCRIPTION

Body, stem, stem axle and screws • Stainless steel

Coupling • Aluminium alloy

Rings, bore and inlet ring • Aluminium alloy

• Hard anodisation

Shutoff handle • Polyamide

Head bumper and pistol handle • Polyurethane

Valve axle • Brass

• Construction

• Hydraulic Characteristics

• Mechanical Characteristics

DESIGNATION DESCRIPTION

Flow rate • 180 lpm @ 20 bar

Max. working pressure • 40 bar

Test pressure • 60 bar

Flow rate adjustment • By turning ow rate adjustment ring

• 55, 110 and 180 lpm - Position ‘‘FLUSH’’ at stop

Type of diffusion • Spinning teeth

• Hallow cone diffusion

Stream pattern adjustment

• By turning head ring

• Straight stream, attack stream (35°) or full fog

diffusion spray (130°)

Shutoff • With ball valve

DESIGNATION DESCRIPTION

Inlet

• Swivelling, 3/4’’ BSP female thread

Note: A different coupling is available upon request. See our

catalogue for more information on couplings.

Filter • Yes, stop particles larger than Ø 5 mm

Flush • By ow rate adjustment ring rotation

POK SAS - ZI Les Guignons - 10400 Nogent-sur-Seine - FRANCE

Tel: +33 (0)3 25 39 84 78 - Fax: +33 (0)3 25 39 84 90 - Email: [email protected] - Web: www.pok.fr 9

MOP_LAM_01403_EN_A - 24/02/2017 - Copyright© POK SAS - Illustrations are only informative

AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth

0

50

100

150

200

250

300

0 5 10 15 20 25 30 35 40

Débits / Flow rate (l/min)

Pression / Pressure (bar)

Courbes débits/pression

55 l/min

110 l/min

180 l/min

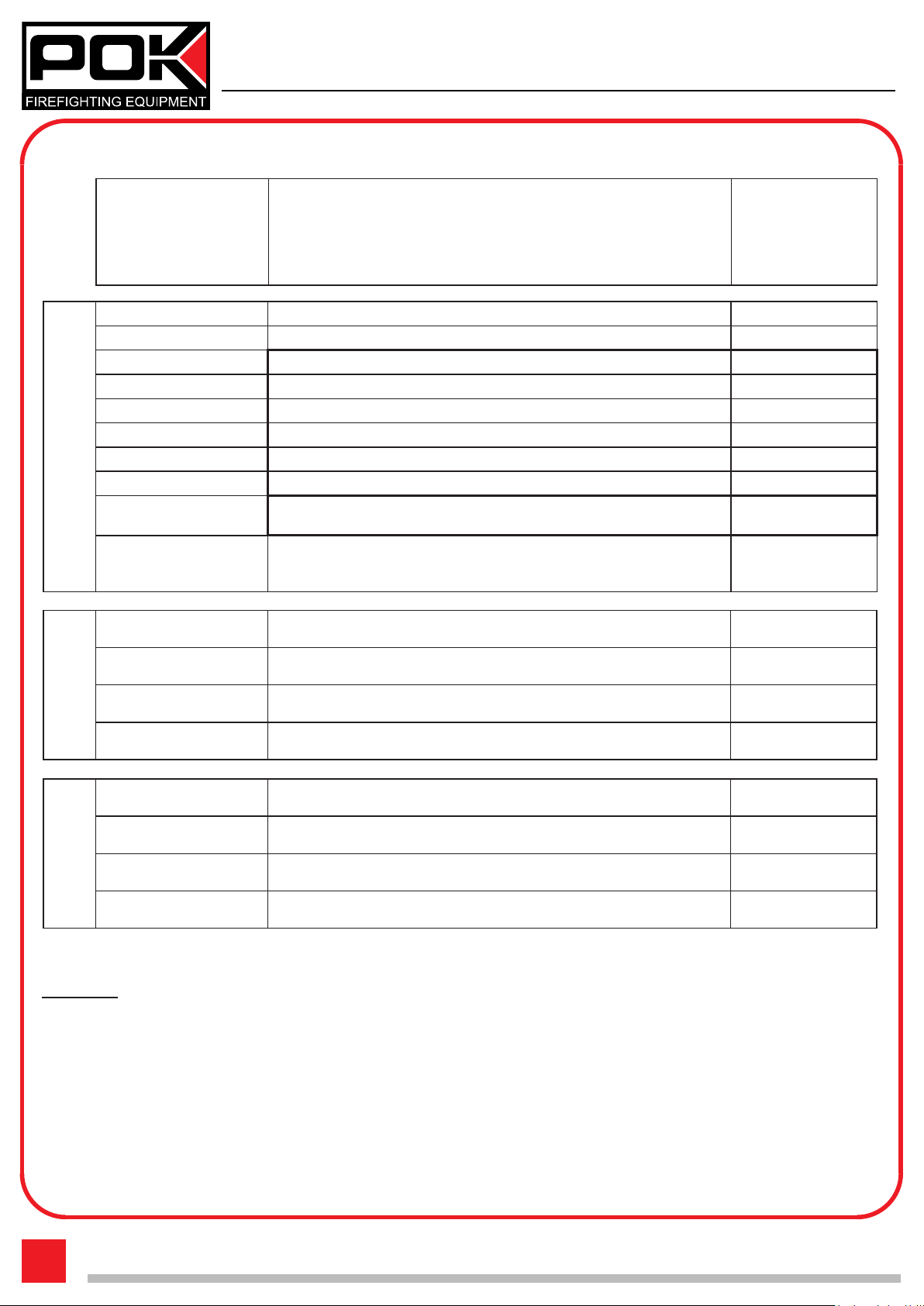

Technical data

Characteristics

1 - General data

3 - Mechanical System

2 - Flow rate / pressure curve

1.1 - Manufacturer POK

1.2 - Type AQUASTAR

1.3 - Flow rate at PR180 lpm @ 20 bar

1.4 - Selectable ow rate 55, 110 and 180 lpm

1.5 - Type of diffusion Hallow cone diffusion

3.1 - Connection system Swivelling

3.2 - Gripping device Pistol handle

3.3 - Opening / closing device With ball valve

3.4 - Straight stream / Fog stream device Rotating part

3.5 - Flow rate adjustment system Rotating part

3.6 - System of purge or ush Rotating part

Bar

55 lpm

180 lpm

110 lpm

lpm Débit

/ Flow rate

Throw range in meters, at 20 bar

55 lpm 110 lpm 180 lpm

Straight stream range (m) 20 27 32

POK SAS - ZI Les Guignons - 10400 Nogent-sur-Seine - FRANCE

MOP_LAM_01403_EN_A - 24/02/2017 - Copyright© POK SAS - Illustrations are only informative

10

AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth

Characteristics

Technical data

4 - Prescriptions

Number of the

party and of the

corresponding

paragraph of the

standard

EN 15182

DESCRIPTION Test results

CONTROL and HANDLING

- 2 / § 4.2.1 Dimensions (mm) 260 x 95 x 224

- 2 / § 4.2.1 Weight (kg) 1.62

Torques needed for moving operating elements (N.m)

Lever

- 2 / § 4.2.2.1 Shutoff handle

Selectable ow rate element ( N.m )

- 2 / § 4.2.2.1 Selective ow pattern ring

- 2 / § 4.2.2.1 Inlet swivel coupling

- 2 / § 4.2.3 Flow rate adjustment

Rotation from minimum to maximum ow rate 90°

- 2 / § 4.2.4

Jet adjustment

Rotation from straight stream to full fog with a minimum spray

angle of 100°

155°

PERFORMANCES

- 2 / § 4.3.3 Effective throw (m) 32

Spray

- 2 / § 4.3.4 Full fog: angle 130°

- 2 / § 4.3.5 Narrow spray: angle 35°

PHYSICS

- 1 / § 7.2.2 Cold resistance (°C) -25°C

- 1 / § 7.2.1 Heat resistance (°C) +80°C

- 1 / § 6.3.1 Non-obstruction test (mm) 5

- 2 / § 4.3.5 Brusting pressure (bar) > 100

5 - Certi ed by:

POK SAS

ZI Les Guignons

10400 Nogent-Sur-Seine

POK SAS - ZI Les Guignons - 10400 Nogent-sur-Seine - FRANCE

Tel: +33 (0)3 25 39 84 78 - Fax: +33 (0)3 25 39 84 90 - Email: [email protected] - Web: www.pok.fr 11

MOP_LAM_01403_EN_A - 24/02/2017 - Copyright© POK SAS - Illustrations are only informative

AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth

AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth

Control and operating

Instructions for use

Note: To obtain optimal performance, respect the following limits:

- Flow rate: 180 lpm

- usage pressure: 20 bar

• Before applying pressure

- 1 - Verify that there are no missing or damaged pieces.

- 2 - Check that the re nozzle is correctly connected to a water supply.

• Openning

The shutoff handle allow a smoth opening and closing, and avoid water

hammer.

NARROW SPRAY

• Adjusting the ow rate and ush

Adjustable ow rate and ush by swivelling ow rate ring. The available

ow rates are engraved on the ow rate adjustment ring. By rotating the

ring to the desired setting, the ow rate will be set to this value at the 20

bar (290 PSI) reference pressure.

A tactile indicator permits the user to know the maximum ow setting

even in total darkness and while wearing re ghting gloves (conform to

EN 659).

This ring also has a position marked FLUSH. This position permits the

removal of particles which could interfere with the proper hydraulic

operation of the nozzle.

• Jet adjustment

Selectable stream pattern: a continuous rotation of the head ring allows

the user to progress from a straight stream to a narrow spray "Flash

Over” (35°), to a full fog diffusion cone (130°) forming a wall of water.

Tactile and visual indicators permit the user to know the type of stream

even in total darkness and while wearing re ghting gloves.in compliance

to standard EN 659.

Position

55 lpm

Position

FLUSH

Position

110 lpm

Position

180 lpm

STRAIGHT STREAM FULL FOG DIFFUSION

Position

Position

Position

Position

POK SAS - ZI Les Guignons - 10400 Nogent-sur-Seine - FRANCE

MOP_LAM_01403_EN_A - 24/02/2017 - Copyright© POK SAS - Illustrations are only informative

12

AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth

Maintenance

• assembly/disassembly

The inlet coupling leaks or does not swivel freely

- Remove the screw mark 19

- Remove all ball bearings mark 17 while turning the coupling mark 18

- Remove the inlet coupling mark 18

- Replace inlet gasket mark 20

- Clean and apply grease ( Loctite 8106) to the ball bearing seat mark 15 and 18

- Apply grease mark 20 (Loctite 8106)

- Install inlet coupling mark 18 on the body mark 15

- Insert all ball bearings mark 17

- Glue (Loctite 243) and screw mark 18 up to the slight contact with the balls, then unscrew 1/4 of a turn

The shutoff leaks

Ensure that no foreign body prevents the shutoff from closing. If there is not any, return us the nozzle.

The ow pattern ring doesn’t turn

- Unscrew the set screw mark 33 (beware of the spring mark 29 and the ball bearing mark 30)

- Remove the head bumper mark 37

- Unscrew the guide mark 32

- Remove the guidance ring mark 31

- Replace inlet gasket mark 24

- Clean and grease (Loctite 8106) the guidance ramp and the surfaces of the mark 25 - 23 and 31 being in

touch.

- Install the guidance ring mark 31

- Glue (Loctite 243) and screw guide mark 32 up to the slight contact with the bore mark 23, then unscrew

1/8 of a turn.

Ensure that the head ring turns freely then install the head bumper mark 37

- Install the spring mark 29 then the ball bearing mark 30 in the index mark 33 then glue (Loctite 243) and

screw everything in place on the head ring mark 31 up to the slight contact with the bore mark 23, then

unscrew 1/8 of a turn.

The spinning teeth is broken or doesn’t turn

- Remove the head bumper mark 37

- Remove the screw mark 35

- Remove the head ring mark 34 and spinning teeth mark 44

- Clean contact aeras between spinning teeth, head ring mark 34 and the guidance ring mark 36.

- If some teeth are missing or damaged, replace spinning teeth mark 44

- Reassemble the spinning teeth mark 44 and the head ring mark 34 without grease.

- Glue (Locite 243) and tight 3 screws mark 35

- Replace the head bumper mark 37

The ow pattern ring doesn’t turn

- Remove the ow pattern ring as detailed above

- Unscrew the set screw mark 28 (beware of the spring mark 29 and the ball bearing mark 30)

- Remove the bore mark 25

- Remove the ow rate ring mark 27

- Replace inlet gasket mark 24 and 26

- Clean and grease (Loctite 8106) the guidance ramp and the surfaces of the mark 25 - 23 - 27 and 31

being in touch.

- Replace the ow rate ring mark 27 with spring mark 29 and ball mark 30

- Replce the bore mark 25

POK SAS - ZI Les Guignons - 10400 Nogent-sur-Seine - FRANCE

Tel: +33 (0)3 25 39 84 78 - Fax: +33 (0)3 25 39 84 90 - Email: [email protected] - Web: www.pok.fr 13

MOP_LAM_01403_EN_A - 24/02/2017 - Copyright© POK SAS - Illustrations are only informative

AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth

Maintenance

- Glue (Locite 243) and screw ow rate index mark 28 until a slight contact with bore mark 23 and untight

on a 1/8 revolution

- Ensure that the ow rate ring turns freely

- Reassemble the ow pattern ring as detailed above

• Cleaning

It is recommended to clean the nozzle with clean water inside and outside after each use (manoeuvres have

to be carried under pressure).

It is recommended to dis-assemble the nozzle once a year if the nozzle is used continuously with salt or

brackish water. Clean and dry all components, gaskets, O rings and grease them as per POK Procedure

provided with the spare parts kit available on order. This service can be provided by our workshop, please

contact us for pricing.

If the nozzle is not working properly, ensure that there is no foreign object preventing it from functioning

properly. In this case, please contact us to obtain the procedures of disassembly or return the product for

a repair in our factory.

• Spare parts

Some parts such as gaskets are likely to be changed more or less often depending on the frequency of use,

conditions of use or storage. Please contact our sales department for the prices and after sales conditions.

Refer to the schedule in this document to identify the replacement parts.

• Handling / Transport / Storage

General Information

When unpacking the equipment after transport, check that there is no mechanical damage and/or loose

parts in the interior of the package. In case of damage, the carrier must be informed immediately. In this

case, do not put the equipment into use.

Delivery Information

POK equipment is delivered in a double-walled cardboard box. We use timing equipment to prevent products

from bumping into each other. The package is securely closed with adhesive tape. A delivery note is included

with the equipment.

Shipment of Equipment

In case of reshipping the equipment, or transferring the shipment to other sites, the shipping process above

should be followed.

Storage of Equipment

When storing the device, it is recommended to keep it in its original packaging to protect from humidity,

dust and kept at normal room temperature.

POK SAS - ZI Les Guignons - 10400 Nogent-sur-Seine - FRANCE

MOP_LAM_01403_EN_A - 24/02/2017 - Copyright© POK SAS - Illustrations are only informative

14

AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth

Bill of materials

Exploded view

POK SAS - ZI Les Guignons - 10400 Nogent-sur-Seine - FRANCE

Tel: +33 (0)3 25 39 84 78 - Fax: +33 (0)3 25 39 84 90 - Email: [email protected] - Web: www.pok.fr 15

MOP_LAM_01403_EN_A - 24/02/2017 - Copyright© POK SAS - Illustrations are only informative

AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth

Bill of materials

MARK QTY DESIGNATION REF

1 1 Body 17733

2 1 Ball Ø25 40117

3 1 Left valve axle 40119

4 1 Right valve axle 40118

5 2 O’ring N°7 -

6 2 Elastic pin Ø4 x 25 -

7 1 Shutoff handle 17739

8 2 Ø4 x 15 pin for shutoff handle 13480

9 1 Pistol handle cover 24160

10 1 Screw CS M5 - 20 -

11 1 Nut H M5 -

12 2 Gasket for ball Ø 20 17735

13 2 O’ring Ø30 x Ø2 -

14 2 O’ring N°25 -

15 1 Swivel inlet pipe section 17738

16 1 Outlet section 23195

17 29 Ball Ø4 -

18 1 Inlet coupling 3/4’’ BSP female thread 18719

19 1 Screw STHC PL M6-4 -

20 1 O’ring N°27 -

21 1 Filter 1449

22 1 Flat gasket for bottom thread 3/4" BSP -

23 1 Bore 39218

24 3 Gasket Ø30 x Ø2 -

25 1 Inner Bore 23165

26 1 Gasket Ø22 x Ø2 -

27 1 Flow rate ring 30501

28 1 Flow rate index 23168

29 2 Index spring 8019

30 2 Ball Ø 6,35 -

31 1 Head ring 23190

32 1 Stream guide 23170

33 1 Index knob for ball Ø 6,35 27204

34 1 Spinning teeth holder 144

35 3 Screw STHC PL M4 - 5 -

MARK QTY DESIGNATION REF

36 1 Gasket Ø38 x Ø2,5 -

37 1 Head bumper -

38 1 Cross piece 23171

39 1 Stem axle 23172

40 1 Cap nut -

41 1 Stem 8116

42 1 Nut H M4 -

43 1 Centering cross piece -

44 1 Spinning teeth 149

Exploded view Parts list

POK SAS - ZI Les Guignons - 10400 Nogent-sur-Seine - FRANCE

MOP_LAM_01403_EN_A - 24/02/2017 - Copyright© POK SAS - Illustrations are only informative

16

AQUASTAR - High pressure hand nozzle with selectable ow rate and stream pattern, 180 lpm, spinning teeth

NOTES

Table of contents

Other POK Firefighting Equipment manuals

Popular Firefighting Equipment manuals by other brands

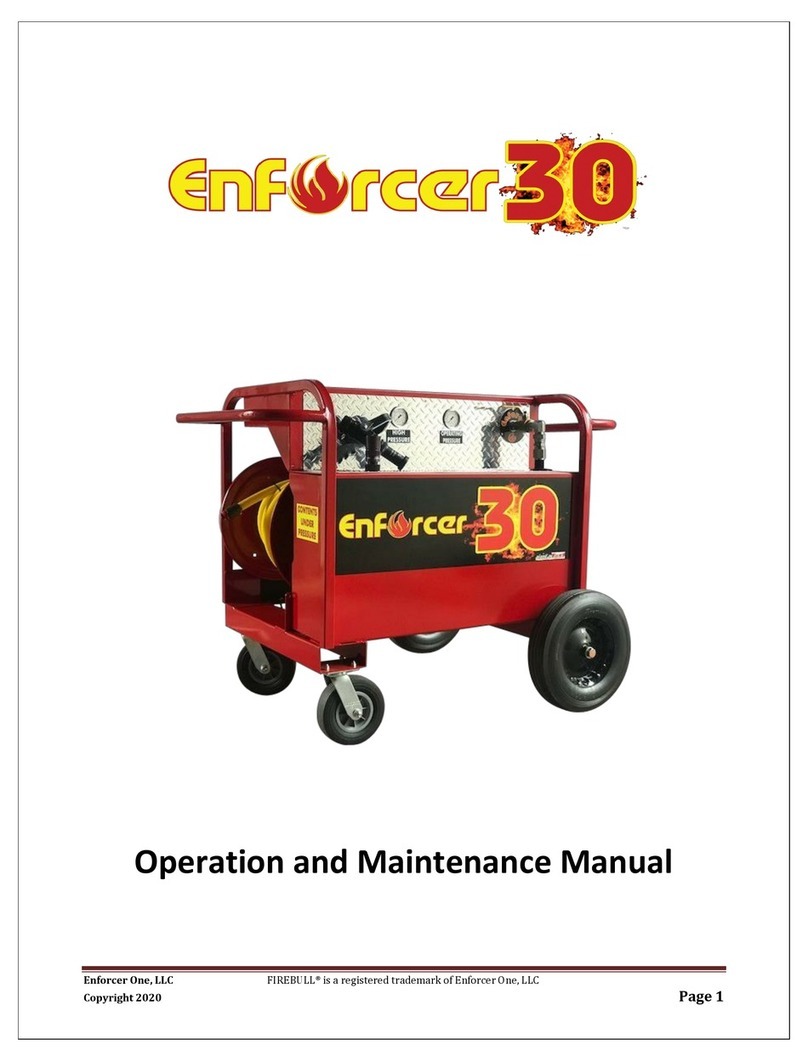

ENFORCER

ENFORCER 30 Operation and maintenance manual

STI

STI EZ-Path 44+ Series installation instructions

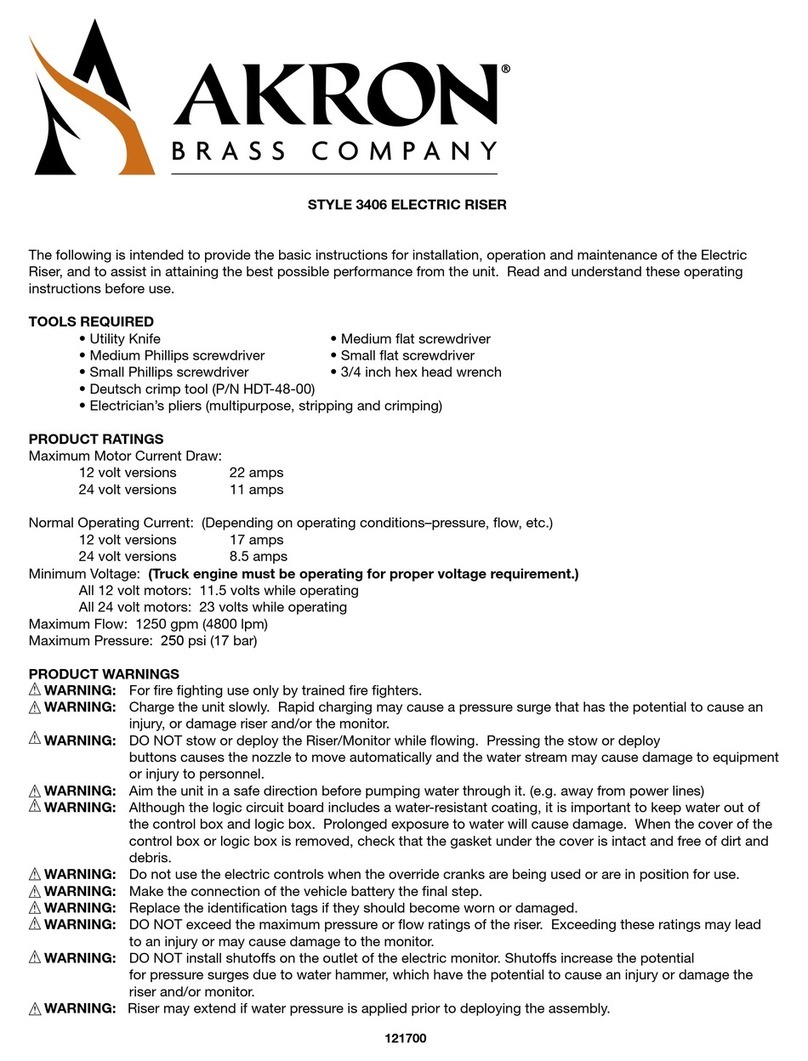

Akron Brass

Akron Brass 3406 quick start guide

Idex

Idex AWG Fittings M0,4 Original operating manual

TFT

TFT TORNADO RC Instructions for installation, safe operation and maintenance

Tyco

Tyco Issue D QUARTZOID quick guide

TFT

TFT Extend-A-Gun XG18 Instructions for installation, safe operation and maintenance

TFT

TFT FoamJet Series manual

Tyco

Tyco TY-FRB Series quick start guide

Projoy Electric

Projoy Electric RSD PEFS-EL Series installation guide

MAS

MAS ENM Series operating manual

SEI Industries

SEI Industries BAMBI MAX BBXHL4000PF Service manual