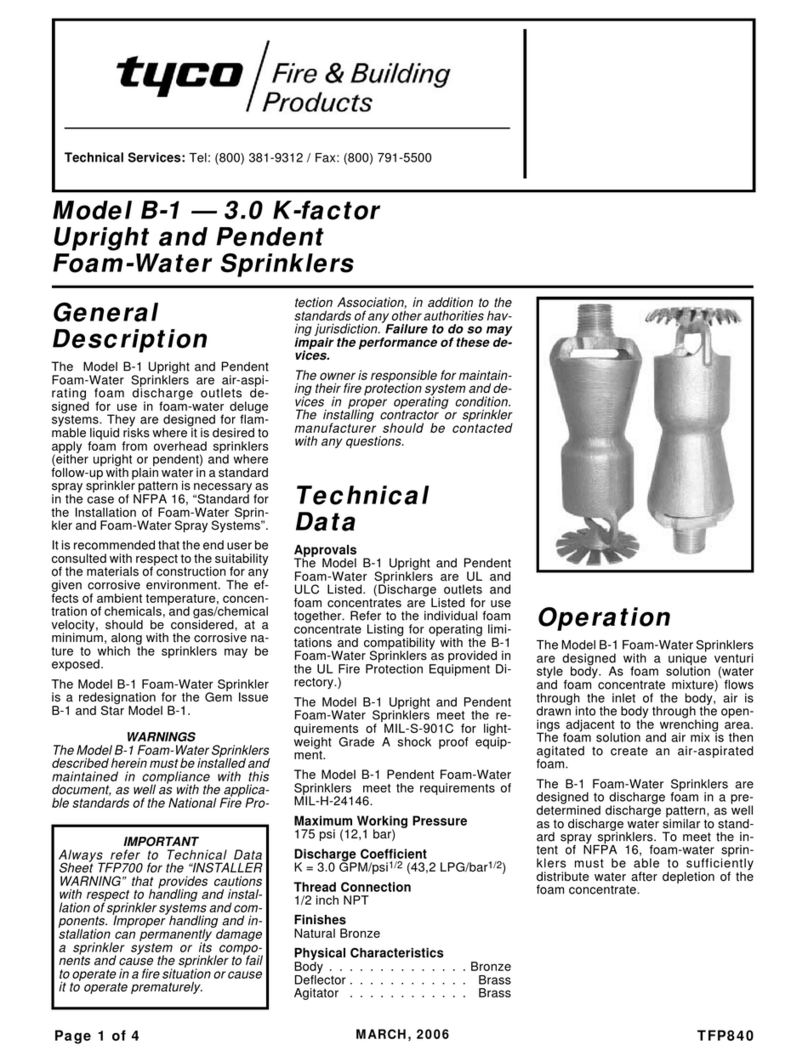

Physical Characteristics

Frame............. Bronze

Button......... Brass/Copper

SealingAssembly ..........

. . . . . Beryllium Nickel w/Teflon†

Bulb...............Glass

Compression Screw . . . . . Bronze

Deflector ...........Copper

Shield.......... PlatedSteel

Operation

The glass Bulb contains a fluid which

expands when exposed to heat. When

the rated temperature is reached, the

fluid expands sufficiently to shatter the

glass Bulb, allowing the sprinkler to

activate and water to flow.

Design

Criteria

The Series TY-FRB Pendent and Up-

right Intermediate Level Sprinklers are

intended for fire protection systems

designed in accordance with the

standard installation rules recognized

by the applicable Listing or Approval

agency (e.g., UL Listing is based on

the requirements of NFPA 13, and FM

Approval is based on the requirements

of FM’s Loss Prevention Data Sheets).

Installation

The Series TY-FRB Sprinklers must be

installed in accordance with the follow-

ing instructions:

NOTES

Do not install any bulb type sprinkler if

the bulb is cracked or there is a loss of

liquid from the bulb. With the sprinkler

held horizontally, a small air bubble

should be present. The diameter of the

air bubble is approximately 1/16 inch

(1,6 mm) for the 135°F/57°C to 3/32

inch (2,4 mm) for the 286°F/141°C

temperature ratings.

A leak tight 1/2 inch NPT sprinkler joint

should be obtained with a torque of 7

to 14 ft.lbs. (9,5 to 19,0 Nm). A maxi-

mum of 21 ft. lbs. (28,5 Nm) of torque

may be used to install sprinklers with

1/2 NPT connections. A leak tight 3/4

inch NPT sprinkler joint should be ob-

tained with a torque of 10 to 20 ft.lbs.

(13,4 to 26,8 Nm). A maximum of 30

ft.lbs. (40,7 Nm) of torque is to be used

to install sprinklers with 3/4 NPT con-

nections. Higher levels of torque may

distort the sprinkler inlet and cause

leakage or impairment of the sprinkler.

— Upright Sprinklers —

The Series TY-FRB Intermediate Level

Upright Sprinklers must be installed in

accordance with the following instruc-

tions.

Step 1. With pipe thread sealant ap-

plied to the pipe threads, hand tighten

the sprinkler into the sprinkler fitting.

Step 2. Tighten the sprinkler into the

sprinkler fitting using only the W-Type

6 Sprinkler Wrench (Ref. Figure 3).

WithreferencetoFigure1or2,the

W-Type 6 Sprinkler Wrench is to be

applied to the wrench flats.

— Pendent Sprinklers —

The Series TY-FRB Intermediate Level

Pendent Sprinklers must be installed

in accordance with the following in-

structions.

Step 1. ThreadtheS2Shieldontothe

sprinkler threads with the stamped

markings toward the deflector and just

to the end of the threads. The final

assembly step is easier to accomplish

if the Shield is not disengaged by con-

tinuing to turn the Shield past the

threads.

Step 2. Roll the O-Ring over the sprin-

kler threads until it seats against the

Shield.

Step 3. With pipe thread sealant ap-

plied to the pipe threads, hand tighten

the sprinkler into the sprinkler fitting.

Step 4. Tighten the sprinkler into the

sprinkler fitting using only the W-Type

6 Sprinkler Wrench (Ref. Figure 3).

WithreferencetoFigure1or2,the

W-Type 6 Sprinkler Wrench is to be

applied to the wrench flats.

Step 5. Rotate the S2 Shield clockwise

(looking up) so that it slightly com-

presses the O-Ring between the

Shield and sprinkler fitting.

Care and

Maintenance

The Series TY-FRB Sprinklers must be

maintained and serviced in accord-

ance with the following instructions:

NOTES

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system that

it controls, permission to shut down

the affected fire protection system

must be obtained from the proper

authorities and all personnel who may

be affected by this action must be no-

tified.

Sprinklers that are found to be leaking

or exhibiting visible signs of corrosion

must be replaced.

Automatic sprinklers must never be

painted, plated, coated or otherwise

altered after leaving the factory. Modi-

fied sprinklers must be replaced.

Sprinklers that have been exposed to

corrosive products of combustion, but

have not operated, should be replaced

if they cannot be completely cleaned

by wiping the sprinkler with a cloth or

by brushing it with a soft bristle brush.

Care must be exercised to avoid dam-

age to the sprinklers - before, during,

and after installation. Sprinklers dam-

aged by dropping, striking, wrench

twist/slippage, or the like, must be re-

placed. Also, replace any sprinkler that

has a cracked bulb or that has lost

liquid from its bulb. (Ref. Installation

Section).

Frequent visual inspections are rec-

ommended to be initially performed for

corrosion resistant coated sprinklers,

after the installation has been com-

pleted, to verify the integrity of the cor-

rosion resistant coating. Thereafter,

annual inspections per NFPA 25

should suffice; however, instead of in-

Page4of6 TFP356

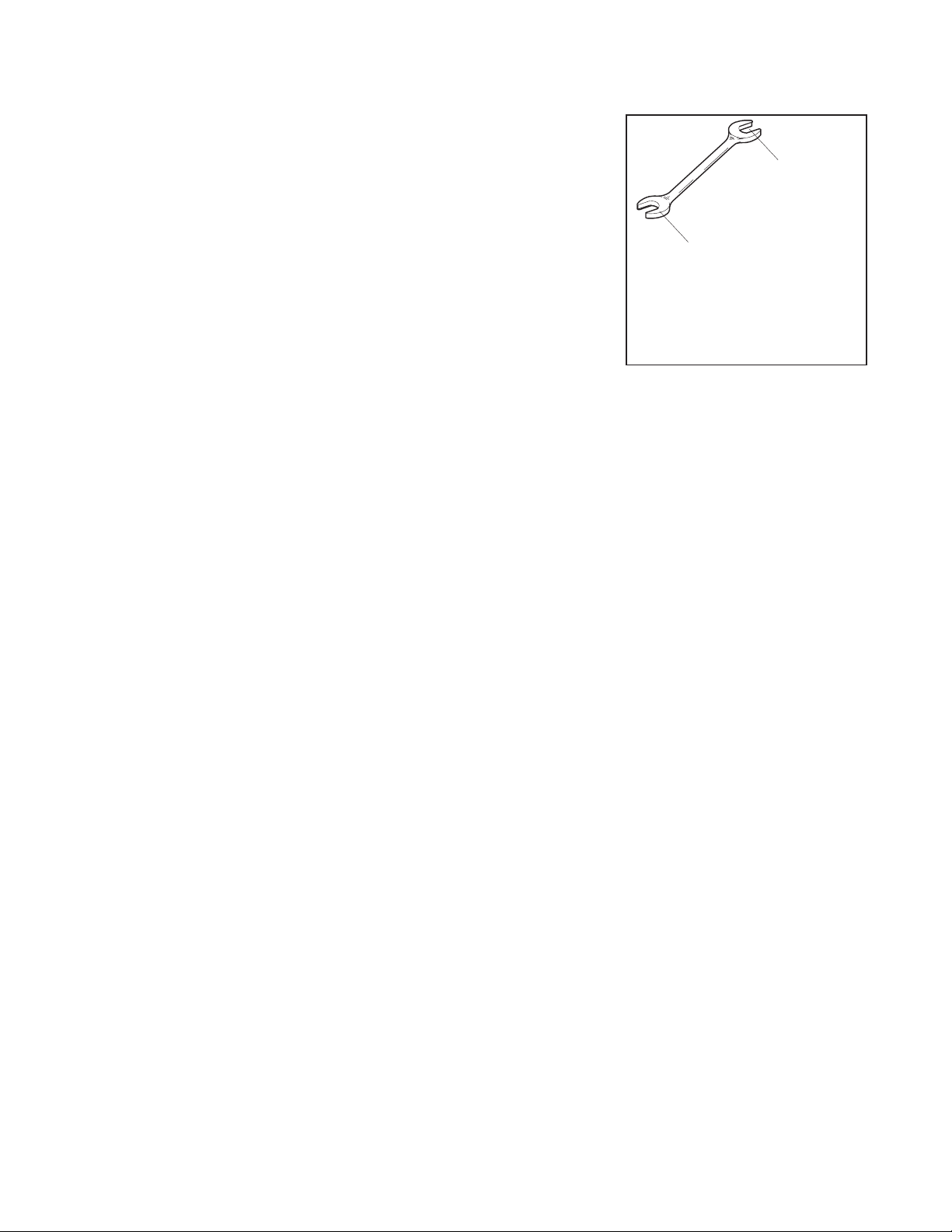

FIGURE 3

W-TYPE 6 SPRINKLER

WRENCH

WRENCH RECESS

(END "A" USED FOR

1/2" NPT MODELS)

WRENCH RECESS

(END "B" USED FOR

3/4" NPT MODELS