1. Overview

The Romi 32U4 Control Board is designed to be assembled with a Romi chassis

[https://www.pololu.com/category/202/romi-chassis-and-accessories] to create a capable integrated robot

platform that can easily be programmed and customized.

Like our A-Star 32U4 programmable controllers [https://www.pololu.com/category/149/a-star-

programmable-controllers], the Romi 32U4 Control Board is built around a USB-enabled Atmel

ATmega32U4 AVR microcontroller, and it ships preloaded with an Arduino-compatible bootloader. The

control board features two H-bridge motor drivers and is designed to connect to a Romi Encoder Pair

Kit [https://www.pololu.com/product/3542] (available separately) to allow closed-loop motor control. It also

includes a powerful 5 V switching step-down regulator that can supply up to 2 A continuously, along

with a versatile power switching and distribution circuit. A 3-axis accelerometer and gyro enable a

Romi 32U4 robot to make inertial measurements, estimate its orientation, and detect external forces.

Three on-board pushbuttons offer a convenient interface for user input, while indicator LEDs, a buzzer,

and a connector for an optional LCD allow the robot to provide feedback.

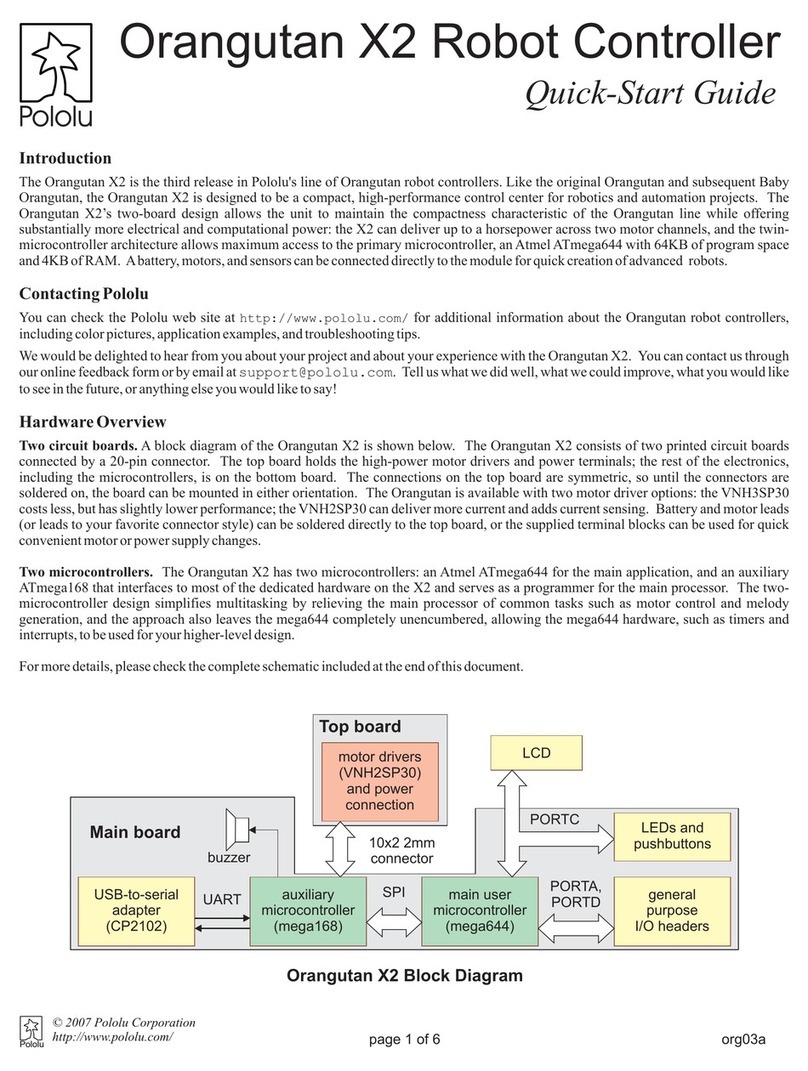

The Romi 32U4 Control Board can be used either as a standalone control solution or as a base for a

more powerful Raspberry Pi controller. Its on-board connector and mounting holes allow a compatible

Raspberry Pi (Model B+ or newer, including Pi 3 Model B [https://www.pololu.com/product/2759] and

Model A+ [https://www.pololu.com/product/2760]) to plug directly into the control board. Integrated level

shifters make it easy to set up I²C communication and interface other signals between the two

controllers, and the control board automatically supplies 5 V power to an attached Raspberry Pi. In

this setup, the Raspberry Pi can handle the high-level robot control while relying on the Romi 32U4

Control Board for low-level tasks, like running motors, reading encoders, and interfacing with other

analog or timing-sensitive devices.

The I/O lines of both the ATmega32U4 and the Raspberry Pi are broken out to 0.1″-spaced through-

holes along the front and rear of the control board, and the board’s power rails are similarly accessible,

enabling sensors and other peripherals to easily be connected.

A software add-on is available that makes it easy to program a Romi 32U4 robot from the Arduino

environment, and we have Arduino libraries and example sketches to help get you started. A USB A

to Micro-B cable [https://www.pololu.com/product/2072] (not included) is required for programming.

1.1. Included components

Pololu Romi 32U4 Control Board User’s Guide © 2001–2019 Pololu Corporation

1. Overview Page 3 of 55