10 ID-E364-001

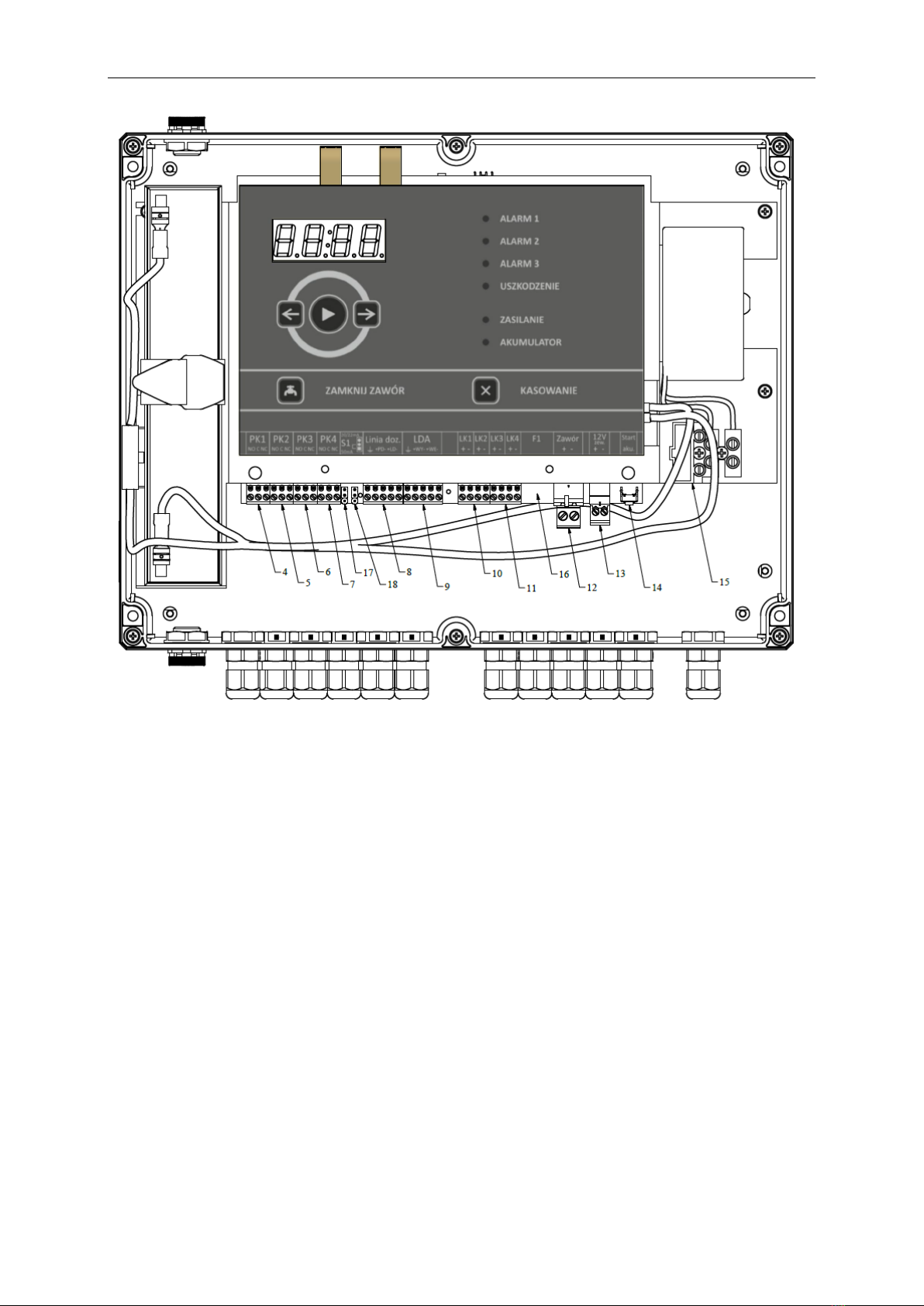

4. Functionality description

4.1. General description

CDG 6000 gas detection control panel is intended for signalization of gas leakages and gas

concentration exceedance and allows for:

-exceedance detection for 3 gas concentration thresholds;

-automatic or manual cut-off valve closure;

-automatic control over 4 devices;

-devices state control;

-automatic control for own modules and control panel circuits;

-transfer of main information (alarm, fault, executive devices state) to parent systems, e.g.

POLON 6000 system.

4.2. Main control panel states

4.2.1. Detection

In the detections state, the power supply indicator should shine continuously on the control panel.

Alarm and fault indicators off. Current time shown on the display. Press arrow button to show

current date on the display.

4.2.2. Alarm signalization

The control panel may signal three alarm stages. Current alarm stage is presented with ALARM 1 – 3

indicators. It is a sum of alarms from all detectors connected with the control panel. Alarm

occurrence in any detector is conveyed with warning indicator light and continuous audible signal.

Blinking indicator and intermittent sound signal informs about stored alarms.

Furthermore, the display presents detailed information on alarm stage for each detector. You can

browse list of detectors signaling alarm with arrow buttons.

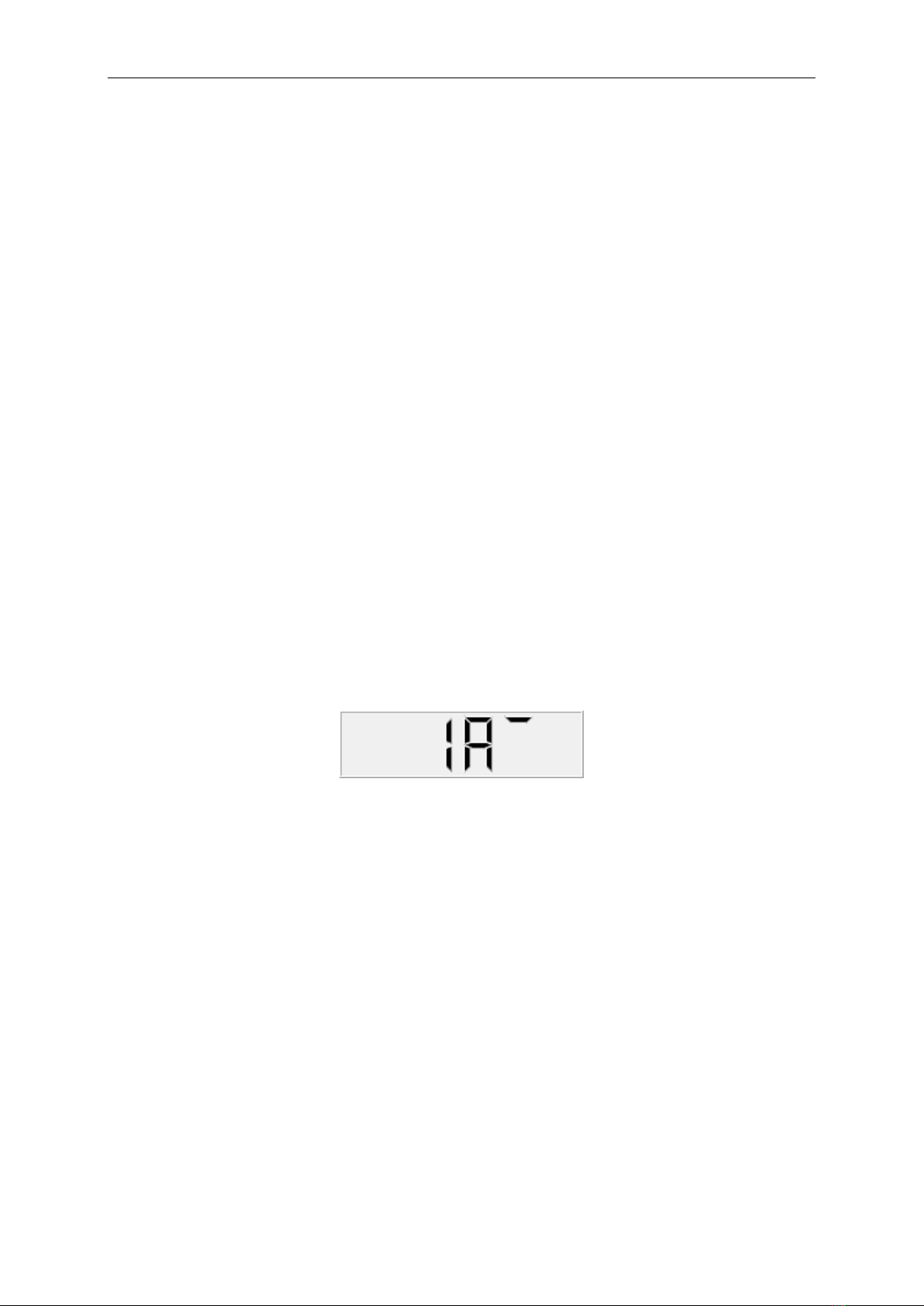

The figure depicts alarms presentation layout on the display. The first two digits are detector

number. The A letter in the third position of the display informs that alarm information is displayed.

Alarm stage is presented in the fourth display position with horizontal number segments. The current

alarm is indicated with continuously lit line. The upper line refers to the first stage alarm, the middle

line refers to the second stage alarm, and the bottom line refers to the third stage alarm. Alarms and

faults are stored in the device until they are cleared by the user. The stored information can be

cleared with CLEAR button on the user panel.

If the detectors are still in the alarm state during clearing, he alarm in the control panel will be

repeated. In order to mute the sound signal press and hold the CLEAR button until a dot is displayed

in bottom right corner. New fault occurrence will automatically trigger the sound signal.

Furthermore, the alarm and fault information is stored in non-volatile internal memory in the form of

event log. The log stores all events with their occurrence date and time. The event log content is

accessible using ”Konfigurator CDG 6000” configuration application.