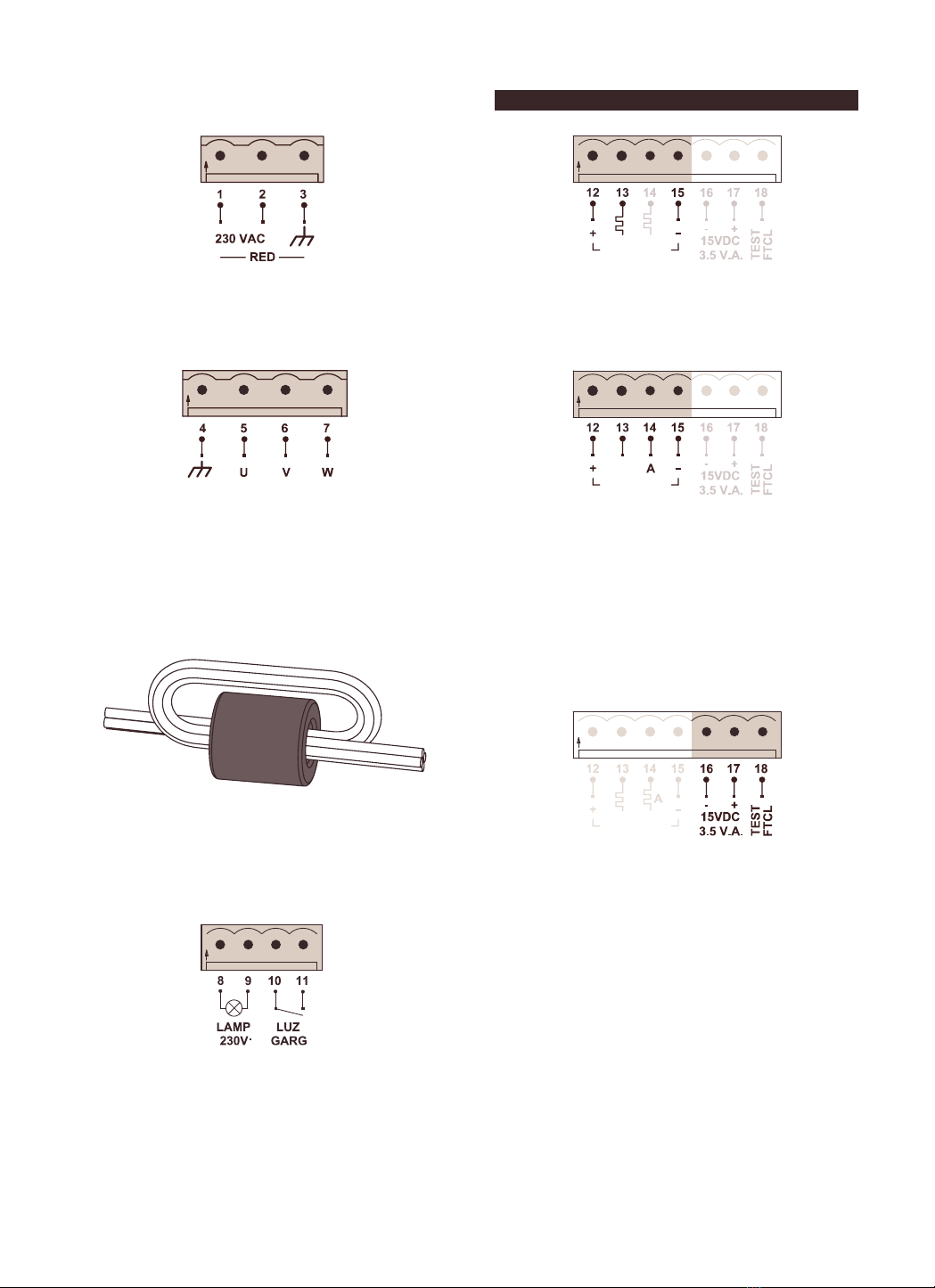

ACTIVATION

The key inputs (marked LL1 and LL2) and a

radio card installed in the radio socket can

be used to start a manoeuvre when the

control unit is idle.

The functions of the key inputs LL1, LL2

and the radio card are determined by the

selected manoeuvre mode. It is possible to

disable any of the LL1 or LL2 inputs using

the LL1 BLOCK or LL2 BLOCK parameters,

so that any stimulus on these inputs will be

ignored.

Each input is assigned a transit direction

to enable the use of discriminating trafc

lights. LL1 and the radio card are used for

the incoming transit direction and LL2 for

the outgoing transit direction (only in

DISCRIM. STD. mode).

NOTE: The radio card operates by default

in the same way as LL1 unless the RADIO

ALT STOP parameter is activated, in which

case it will operate in alternate stop

(regardless of the general manoeuvre

mode selected).

MANOEUVRE MODES

The MANOEUVER MODE parameter sets the

functions that the key and radio inputs

perform.

STANDARD

In STANDARD mode, LL1 will give an open

command if the door is closed and a close

command if the door is open and at rest.

LL2 will function the same except that the

opening will be in pedestrian mode. Either

in p u t w i l l p e r f orm a s o f t r e v e rs a l

manoeuvre when activated during clo-

sing. In this mode, AUTO CLOSE is activa-

ted by default, although in OPTIONS, by

accessing this command, it can be deacti-

vated by selecting NO.

STANDARD DISCRIMINATORY

The DISCRIM. STD. mode is the same as

the STANDARD mode, except that LL1 and

LL2 perform the same function; the former

in the input direction and the latter in the

output direction.

MANOEUVER

OPEN/CLOSE

The OPEN/CLOSE mode uses LL1 as the

opening command and LL2 as the closing

command. When the door is in motion the

opposite direction input will cause a

smooth reversal of manoeuvre (without

passing through stop). In this mode, AUTO

CLOSE is disabled by default, although in

OPTIONS, by accessing this command it

can be activated by selecting YES.

STOP ALT.

The ALT. STOP mode works in the same

way as the STANDARD mode, except that if

LL1 or LL2 is used while the door is moving,

it stops. The next press will make the door

continue the manoeuvre in the opposite

direction to the previous one. In this mode,

the AUTO CLOSE is disabled by default,

although in OPTIONS, by accessing this

command, it can be activated by selecting

YES.

DEADMAN

The DEADMAN mode only allows the door

to move while the LL1 or radio input is

active (opening) or the LL2 input is active

(closing). The manoeuvre is interrupted

when the input in use is deactivated. In this

mode , the sa feti es only pause the

manoeuvre.

SEMI. DEADMAN

The SEMI. DEADMAN mode performs full

opening in the normal way when using LL1

or LL2, but requires using either of the

inputs in deadman mode to close.

AUXILIARY DEADMAN

The parameter AUX DEADMAN parameter

allows the panel to temporarily operate in

deadman mode when one of the safeties

fails the test, allowing the door to be

opened in case of problems. When this

option is activated, in the event of a failure,

simply press and hold the usual key or

radio input for a few seconds.

8

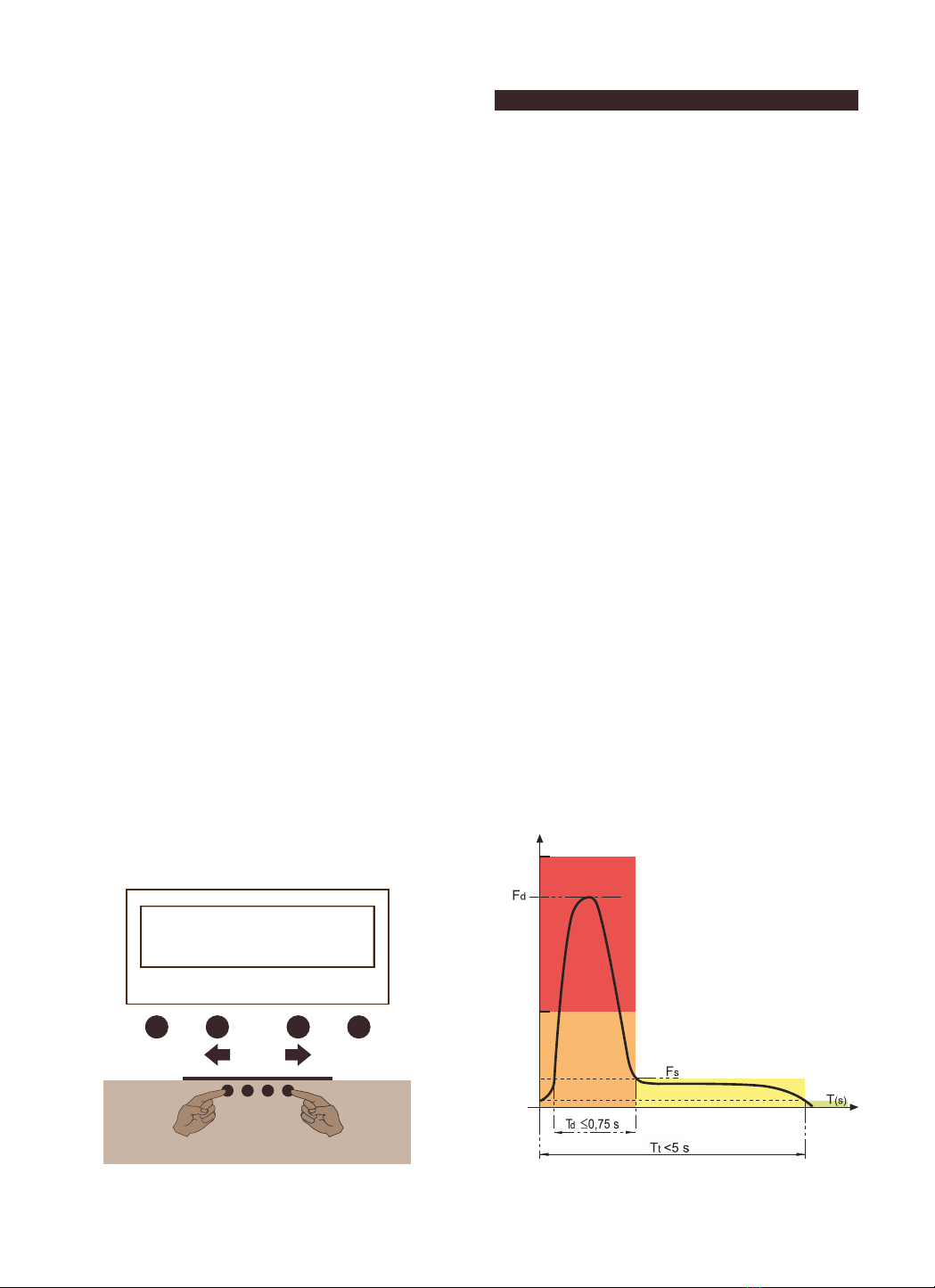

PHASES

SAFETY TESTS

The safety tests phase is performed in the

beginning of every maneuver before

moving the gate. The controller rst

checks for obstructed safeties (corres-

ponding led off in the board) that are

relevant to the maneuver. If there is any

obstructed safety it waits for them to

enter idle state and will show a message in

the display to this effect. Then the board

checks the resistive values of safety edges

and performs a test procedure on light

barriers removing power from the trans-

mitter to check the system is in order.

UNLOCKING

The unlocking phase performs many

different functions simultaneosly before

starting the movement phase:

wActivates the garage light relay during

the time interval specied by the GARG

LIGHT T parameter. This paremeter can

be set to any time from 1 sec. to 240

sec., thus saving the need to use an

external timer.

wActivates the electrolock relay if any of

the relays is congured as such and the

ELECTROLOCK parameter is set with a

time interval.

wWhen the electrolock is activated and

the maneuver will open the gate the

controler performs a reversing stroke in

soft stop speed ( OP SOFT VEL parame-

ter) with normal power (OP NORMAL POW

parameter) for a duration specied by

the REVERS. STROKE parameter.

wPerforms preashing through a relay

congured for light beacon during the

time interval specied by the PREFLASH

OP T parameter for opening and the

PREFLASH CL T for closing. Preashing

is managed following the mode speci-

ed by the PREFLASH MODE parameter. If

the FLASHING SEM. parameter is set

preashing will be performed through a

relay congured as red semaphore

light.

MANOEUVER

MOVEMENT

The movement phase comprises the

actual gate movement and management

of the safety devices. First the red semap-

hore light is activated if any relay is set as

such and the maneuver counters are

incremented (once per gate movement

direction). The electrolock, if activated in

the previous phase, is held active until the

time specied by the ELECTROLOCK

parameter passes. If there is a relay set up

as a beacon light it will be managed

following the mode set in the FLASH MODE

MOV parameter.

Motor speed and power are adjusted in

different phases:

wAcceleration ramp: The acceleration

ramp is performed at maximum power

and goes from stopped motor to the

transit speed in the time specied by the

OP ACCEL RAMP parameter for opening

and CL ACCEL RAMP for closing. The

shorter the ramp time the more abrupt

the speed change is, and the longer the

r a m p , s o f t e r t he s pe e d c h a n g e .

wTransit: In transit the motor spins with

the the speed and power adequate to

the maneuver. Most maneuvers are

performed in normal speed OP NORMAL (

VEL CL NORMAL VEL for opening and for

closing) ( for and power OP NORMAL POW

opening and for clo-CL NORMAL POW

sing). Deadman maneuvers before the

rst learning maneuver are performed

in soft stop speed OP SOFT VEL( for

opening and for closing) CL SOFT VEL

and power ( for opening OP SOFT POW

and for closing)CL SOFT POW .

continues on next page -->

9

ESPAÑOLPORTUGÊSDEUTSCH

NEDERLANDS ITALIANO ENGLISHFRANÇAIS