Overview

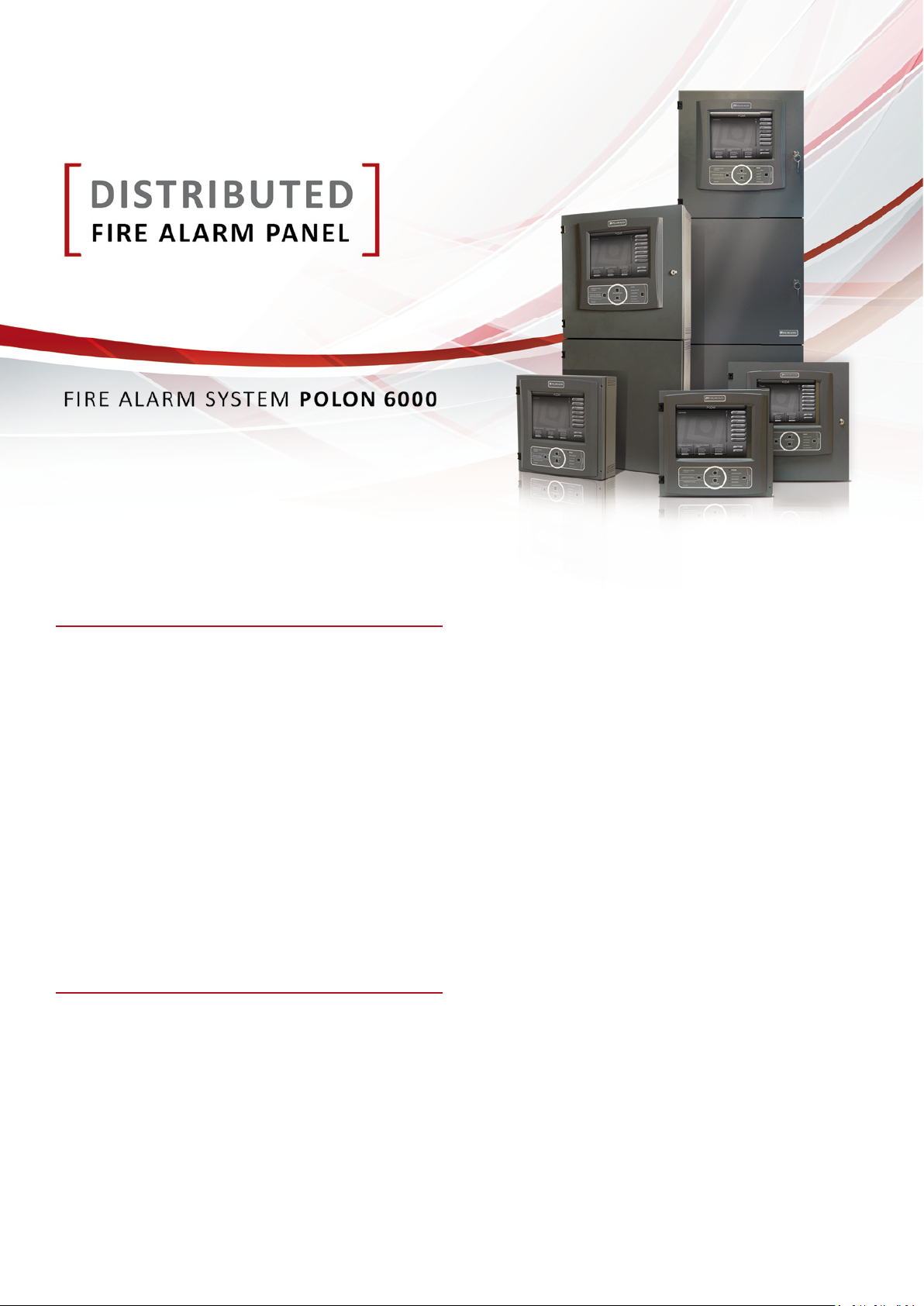

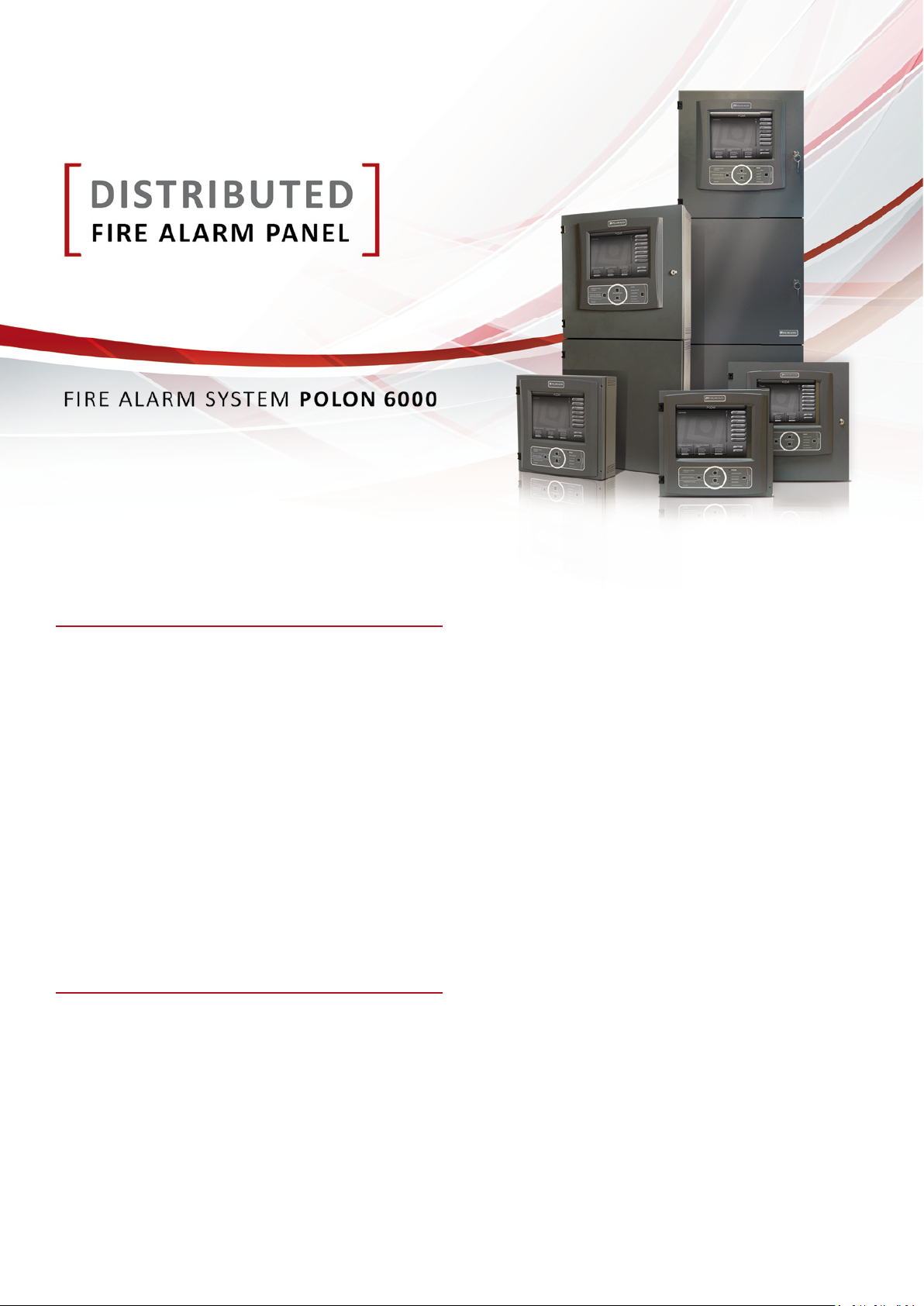

The POLON 6000 control panel

with a distributed architecture

The addressable, interac ve POLON 6000 re alarm system is a set

of latest technology equipment, designed for very fast detec on

and signaling of re, precise indica on of re origin, control of re

protec on safety devices, and informa on of appropriate interven-

on services or building guards about re. It enables protec on of

mid-size, large and very large facili es, especially so called “intelli-

gent” buildings with huge amount of re protec on safety devices.

POLON 6000 can be easily integrated with variety of exis ng buil-

ding management systems. Due to its speci c features it enables

to arrange perfect set of necessary devices, well- ed to site re-

quirements.

The POLON 6000 system is based on newly designed control panels

with distributed architecture and new range of line elements. All

devices of the POLON 6000 system meet requirements of the latest

edi on of EN 54 European Standards.

The POLON 6000 control panel design was based on the idea of a

module device with a distributed architecture. It consists of many

unified modules of various types, installed inside standardized ca-

binets. Cabinets can be arranged as separate units or combined

in sets (so called nodes) and can be located in different places of

site area, even if those locations are distant. All modules within

one node and nodes between themselves are connected with

a common, doubled (redundant) digital communication bus.

Each control panel can be flexibly assembled with modules and no-

des well-fitted to individual building requirements. Such solution

enables the arrangement of the control panel equipment, installed

in required locations. This provides maximum optimization of the

system, reduction costs of installation. All that is possible thanks to

implementation of doubled main processor controllers, communi-

cation buses and connections between nodes.

The POLON 6000 control panel consists of the PSO-60 operation

panels with 10’’ touch screen, functional modules: detection lines

MLD-61 and MLD-62, input-output MKS-60, relay outputs MPK-60,

signalling outputs MWS-60, conventionale line module MLK-60,

high current relay outputs MPW-61, supervision inputs MWK-60,

supply MZP-60 and transmission MTI-61, MTI-62, MTI-63 v2.

PSO panels and modules are installed inside the cabinets with stan-

dard dimensions, which can be mechanically binded. A set of such

mechanically connected cabinets create a control panel node. The

control panel need to have at least one node in which main con-

trol panel PSO-60 (having number 1) is installed. This is the “main

node” of the control panel. There is always only one “Main node”

in the system. The rest of elements (modules) of the control panel

is configured in form of external nodes which are connected to

the “main node”. The communication between nodes is provided

by double cable connection (RS-485) or double fiber optic cables.

Each node shall be equipped – depending on the size of node and

expected current consumption – with one or more supply modules.

Each node can contain line modules with connected detection lines,

input-output modules for direct control or supervision of fire safety

devices. In each external node the PSO-60 panel can be implemen-

ted, acting as the parallel operation panel.