IK-E283-001E 3

Contents

1. Introduction...........................................................................Error! Bookmark not defined.

1.1. Documentation contents ...................................................Error! Bookmark not defined.

1.2. Control panel application...................................................Error! Bookmark not defined.

1.3. Safety conditions................................................................Error! Bookmark not defined.

1.3.1. Electric shock protection............................................Error! Bookmark not defined.

1.3.2. Installation and eqipment safety................................Error! Bookmark not defined.

1.3.3. Repair works and maintenance..................................Error! Bookmark not defined.

1.3.4. Fuse replacement.......................................................Error! Bookmark not defined.

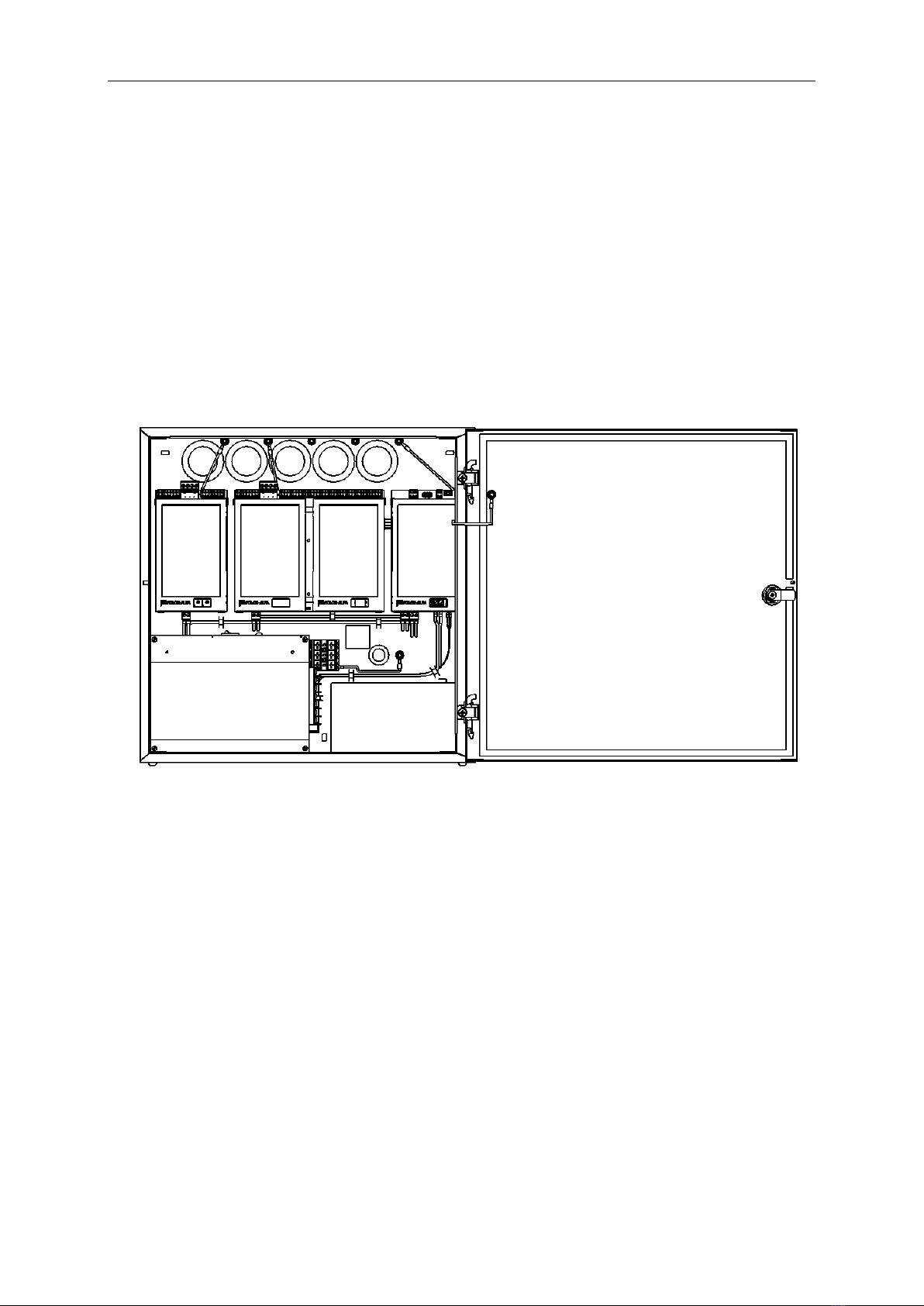

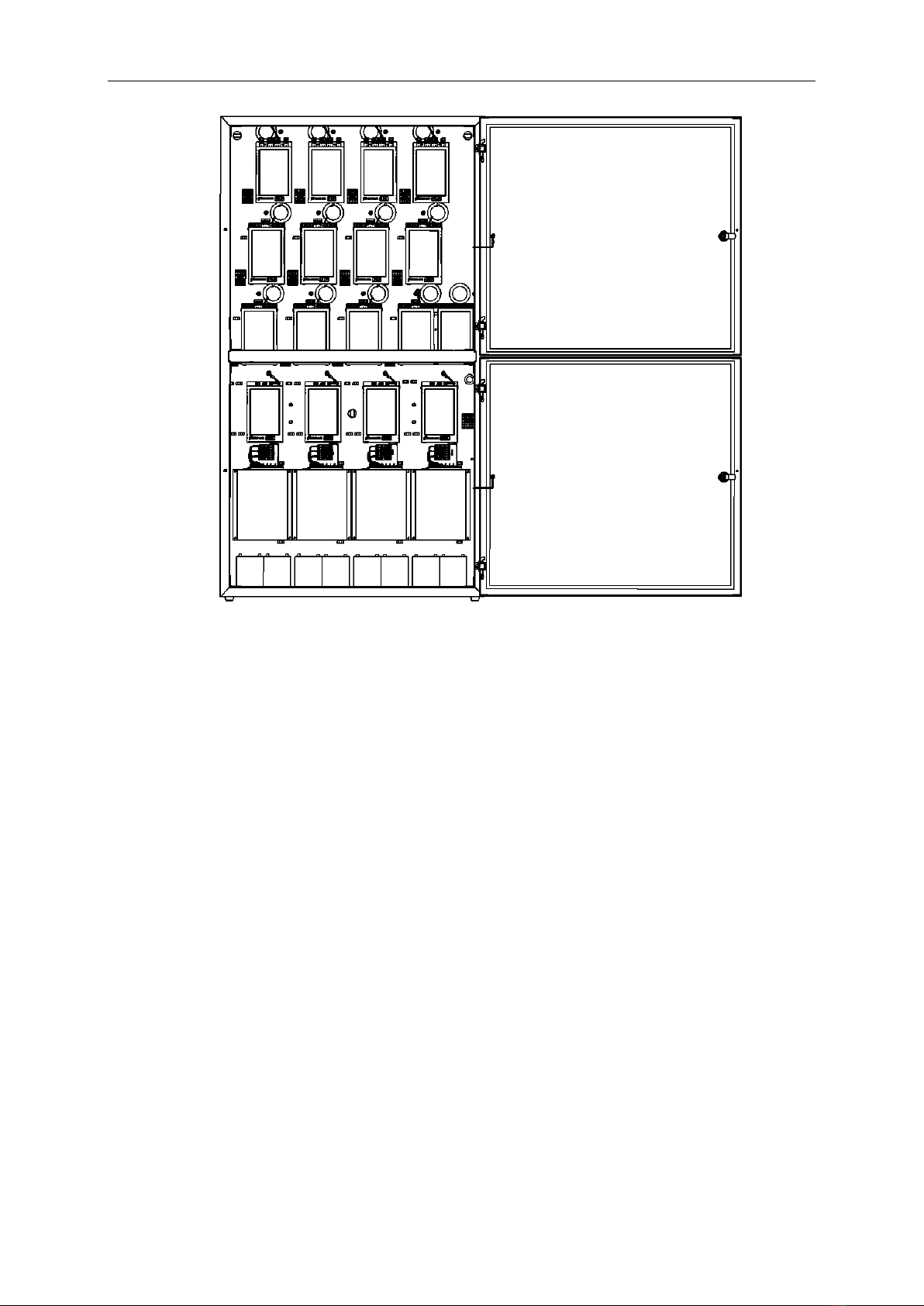

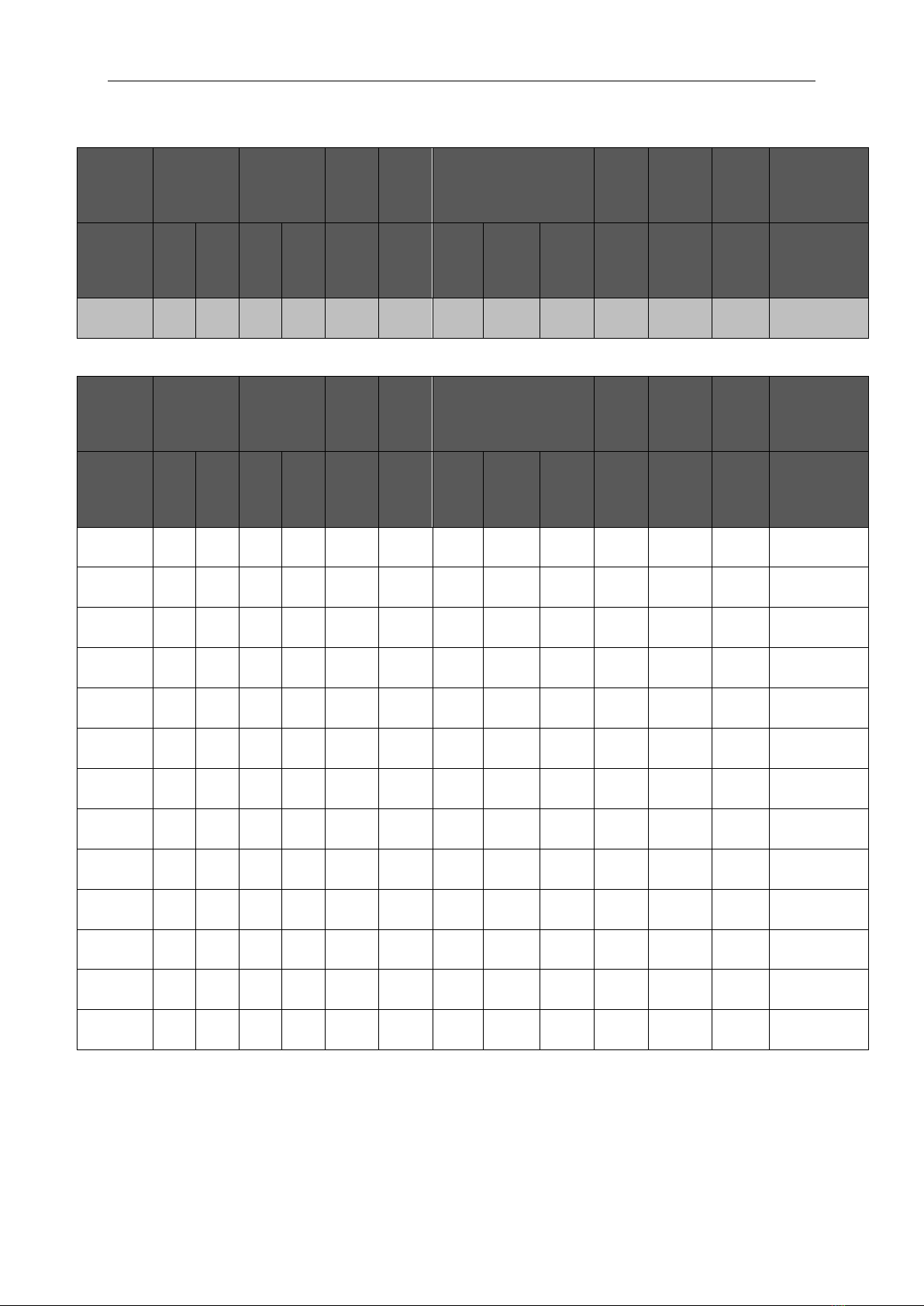

2. Control panel design and completeness ...............................Error! Bookmark not defined.

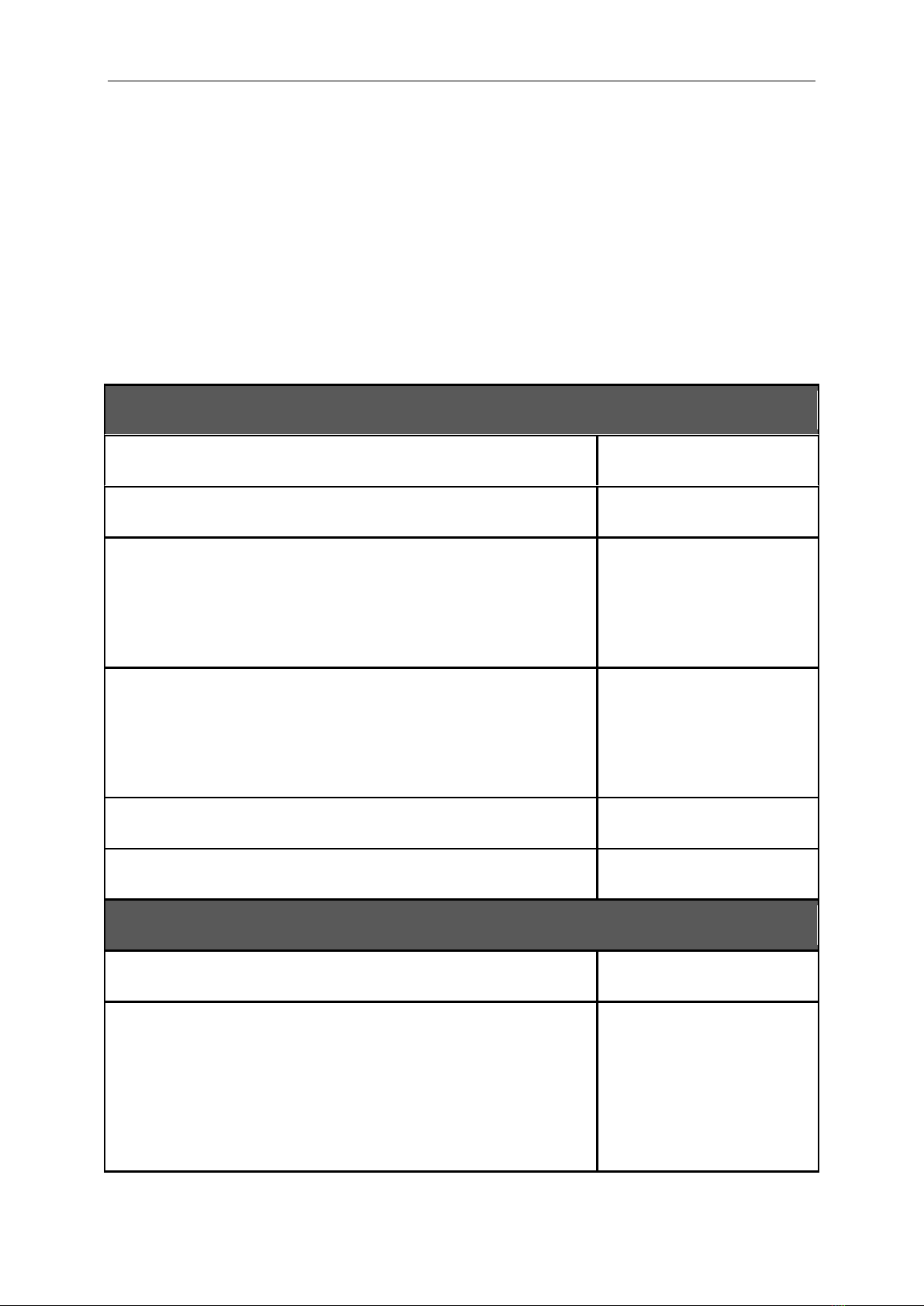

3. Technical specifications.........................................................Error! Bookmark not defined.

4. Functionality description.......................................................Error! Bookmark not defined.

4.1. General description............................................................Error! Bookmark not defined.

4.2. Control panel basic operation modes................................Error! Bookmark not defined.

4.2.1. Quiescent mode .........................................................Error! Bookmark not defined.

4.2.2. Daytime airing function..............................................Error! Bookmark not defined.

4.2.3. Alarming –fire protection devices actuation.............Error! Bookmark not defined.

4.2.4. Fault............................................................................Error! Bookmark not defined.

5. Connecting external circuits..................................................Error! Bookmark not defined.

5.1. General information...........................................................Error! Bookmark not defined.

5.2. MGS-60 module .................................................................Error! Bookmark not defined.

5.2.1. External alarm input...................................................Error! Bookmark not defined.

5.2.2. Rain/wind sensor........................................................Error! Bookmark not defined.

5.2.3. PKA alarm relay and PKU fault relay...........................Error! Bookmark not defined.

5.3. MGL-60 module..................................................................Error! Bookmark not defined.

5.3.1. Detection line .............................................................Error! Bookmark not defined.

5.3.2. Smoke exhaust button................................................Error! Bookmark not defined.

5.3.3. Fire-fighting devices output .......................................Error! Bookmark not defined.

5.3.3.1. Operation modes of output to fire protection devicesError! Bookmark not

defined.

5.3.3.1.1. OPERATION MODE - 1 ............................................Error! Bookmark not defined.

5.3.3.1.2. OPERATION MODE - 2 ............................................Error! Bookmark not defined.

5.3.3.1.3. OPERATION MODE - 3 ............................................Error! Bookmark not defined.

5.3.4. Limiting switches ........................................................Error! Bookmark not defined.

5.3.5. Airing buttons.............................................................Error! Bookmark not defined.

5.4. MPW-60 module ................................................................Error! Bookmark not defined.

5.4.1. PK1 and PK2 relays, LK1 and LK2 monitoring lines.....Error! Bookmark not defined.

5.5. MPD-60 module .................................................................Error! Bookmark not defined.

5.5.1. PK1 and PK2 relays, LK1 and LK2 monitoring lines.....Error! Bookmark not defined.

5.6. MKA-60 module .................................................................Error! Bookmark not defined.

5.7. MZU-60 module and power supply....................................Error! Bookmark not defined.

5.7.1. Basic power supply.....................................................Error! Bookmark not defined.

5.7.2. Reserve power supply ................................................Error! Bookmark not defined.

5.7.3. Reserve power supply battery discharge ...................Error! Bookmark not defined.

5.7.4. PKUZ power supply fault relay ...................................Error! Bookmark not defined.

5.7.5. Output to external devices power supply ..................Error! Bookmark not defined.

6. Control panel configuration and programming ....................Error! Bookmark not defined.

6.1. MGS-60 module configuration...........................................Error! Bookmark not defined.

6.2. MGL-60 module configuration...........................................Error! Bookmark not defined.

6.3. MPW-60 module configuration..........................................Error! Bookmark not defined.

6.4. MPD-60 module configuration...........................................Error! Bookmark not defined.