SAFETY CONT.

Only carry tools and materials with you when ascending or descending the tower if

they are safely retained in a tool belt and do not restrict your free movement. Tools

/ materials may be hoisted to the deck via a rope. PROPERLY ASSESS THE RISK

METHOD!

Do not lean from the tower and never apply undue side force. Maximum permitted

side load must not exceed 20Kg (200N). Never use boxes, steps or similar items

to gain additional height. Do not stand on the toeboards, horizontal or diagonal

braces. Always use the towers built in ladders to access platforms and climb from

inside the tower NEVER from outside. When climbing, always keep your feet in the

middle of the rungs and grip the upper rungs with your hands NEVER the sides.

When winds exceed Beaufort force 4, cease to use the tower. Always be aware that

using the tower in situations such as unclad or open ended buildings or on the

corners of buildings could cause additional wind loading of the tower structure.

Wind Speeds

Force Peak

MPH

Peak

KPH Guidance

4

6

8

18

31

46

29

50

74

Moderate breeze - raises dust and loose paper

PREPARATION

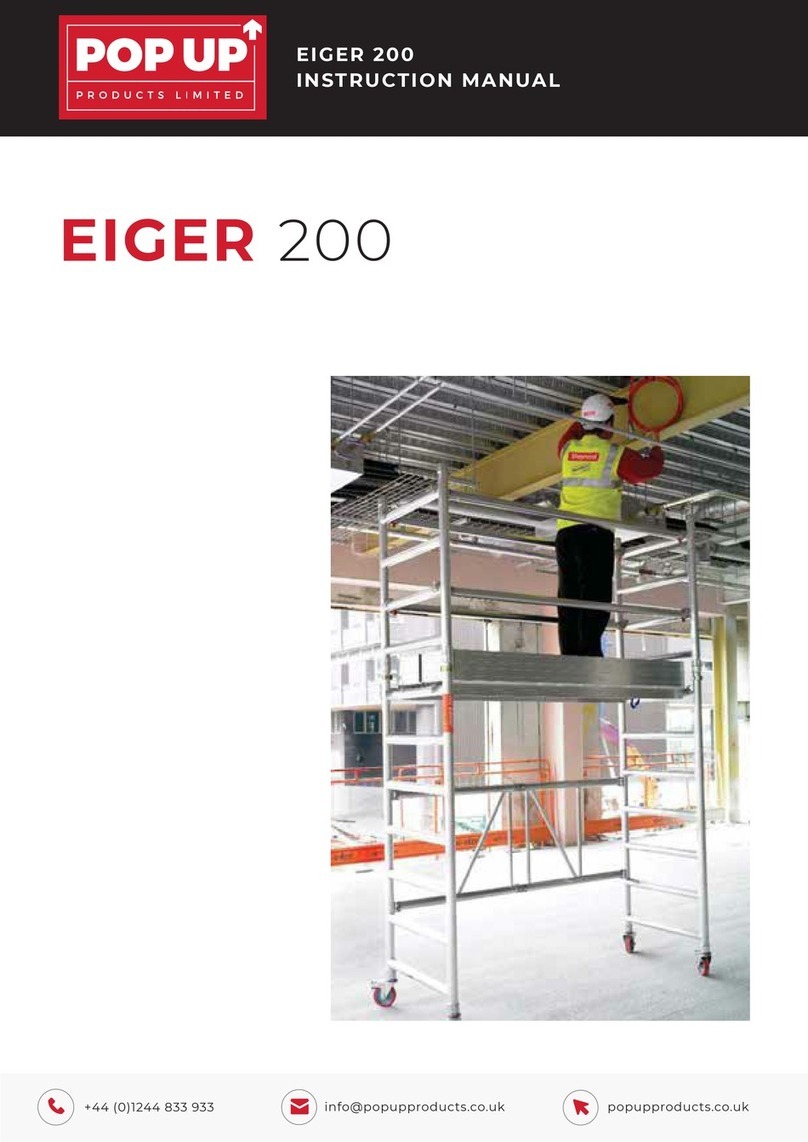

Check the ground upon which the tower is to be used is capable of supporting the

combined weight of the tower and any necessary loading. The ground should be

level and any slope should be within the scope of the adjustable legs. Ensure all

tools and equipment required to erect the tower are available and on site.

Check each component for condition and correct operation BEFORE you start

assembling the tower. Any faulty or damaged items MUST be replaced before

assembling the tower. As you inspect each part, segregate types to make the task

easier.

COMPONENTS

BRACES

oks at both ends.

The triggers, when operated, pull back to allow the hook to be placed over the

tubing used on the tower. Horizontal braces are also used as guardrails.

s) must be attached

to the top of frame horizontal tube. Always double check that each hook is

positively locked onto the tubing before using the tower.

The brace hook trigger mechanisms are colour coded to show which are horizontal

braces and which are diagonal braces. Horizontal brace triggers are coloured red

and diagonal brace triggers are coloured blue.

TYING IN

Please refer to PASMA guide ‘Tying in Mobile Towers’ available for download at

http://pasma.org.uk/shop or contact PASMA for a hard copy. tel. 0845 230 4041

DISMANTLING THE TOWER

Dismantle the tower by reversing the erection sequence. You MUST always be

protected by a full set of guardrails when standing on a platform and removing

components.

EQUIPMENT MAINTENANCE &CLEANING

Keep all components clean and free from contaminants. If any part becomes

contaminated with paint, acid, oils or similar products the tower must not be used

.

TRANSPORTATION & STORAGE

All components should be stored in a dry location where they will be protected

from adverse weather conditions. When storing or transporting, keep frames

ress damage.

INSTRUCTION LEAFLET AVAILABILITY

Keep these instructions in a safe place and ensure that they are made available to

anyone using, constructing or dismantling the tower. If these instructions become

lost or illegible, replacements should be acquired from the manufacturer.

DAMAGED COMPONENTS

Damaged components found during inspection must be quarantined until assessed

ents.

DO NOT use damaged components in the tower structure.

BALLAST

Where shown in the component list, ballast must be used to stabilise against

overturning. Only use solid materials as ballast (i.e. no loose materials) and position

to avoid overloading individual components. Ballast should be supported by the base

of the tower and securely fastened to prevent removal.

ADVANCED GUARDRAIL (AGR) PANELS

This method of construction reduces the risk of a fall from height. You will complete

an ‘assembly / access’ platform level from which is added the ‘next lift’ of frames, AGR

er is achieved.

be protected by a set

of guardrails. Attaching the AGR panels from an assembly platform level provides the

erector with a set of guardrails for the next lift of the tower. In this way the erector is

protected from a fall in advance to accessing the next assembly platform or working

platform.

EngagedDisengaged

Easy-Clip Frame Clips

The Easy-Clip frame clip’s pin locates into

aretaining hole in the frames to lock

tower sections together when placed one

on top of the other. The pin is locked in

place by a red tab to ensure that it

remains in place. From the disengaged

position, pivot the pin/tab to bring the pin

horizontal. Insert the pin fully through the

retaining hole with its tail pointing down.

Next flip the tab vertically to lock the pin

in place.Removal is simply a reversal of

the fitting sequence.

Easy-Lock Stabiliser

The Easy-Lock clamps are used to secure

the stabilisers to MiSTAIRS’s vertical

tubing. With the clamp jaw open, offer it

to the tube. Bring the jaw around the

tube and set the buckle on to the hook,

then close the black clamp arm to lock

the stabiliser in position. A similarclamp

is fitted to the stabiliser extension leg.

Wind-Lock Catch

The Wind-Lock catch is a drop down jaw

fitted to the side of the hatch platform’s

mounting hook and prevents the platform

from lifting in windy conditions. It is

attached to the horizontal tube of the

frame. To disengage, simply lift and hold

the jaw as you raise the platform clear.

ADVANCE GUARDRAIL PANELS (AGR)

The AGR panels consist of both horizontal bracing and diagonal bracing members in

a panel which can be attached to the tower from a safe guarded position.The

horizontal bracing elements within the panel also act as a set of ‘integral’ guardrails

an as such provides automatic guarding in advance to accessing the next level or lift

of tower.The panels are attached by means of the same type of triggered hook as the

horizontal and diagonal braces. The triggered hooks are found at the base of the

panel and another pair of hooks can be found at the top of the panel. However these

hooks are not triggered and are simply placed over the horizontal frame tubes. The

triggered hooks at the base are used to positively lock the panel in position. Place the

upper hooks over the horizontal frame tube 2m above the assembly platform and

then ‘snap the triggered hooks onto the lower horizontal frame tubes.