Page 4

V 1.3 – February 2016

U s e r I n s t r u c t i o n M a n u a l

Introduction

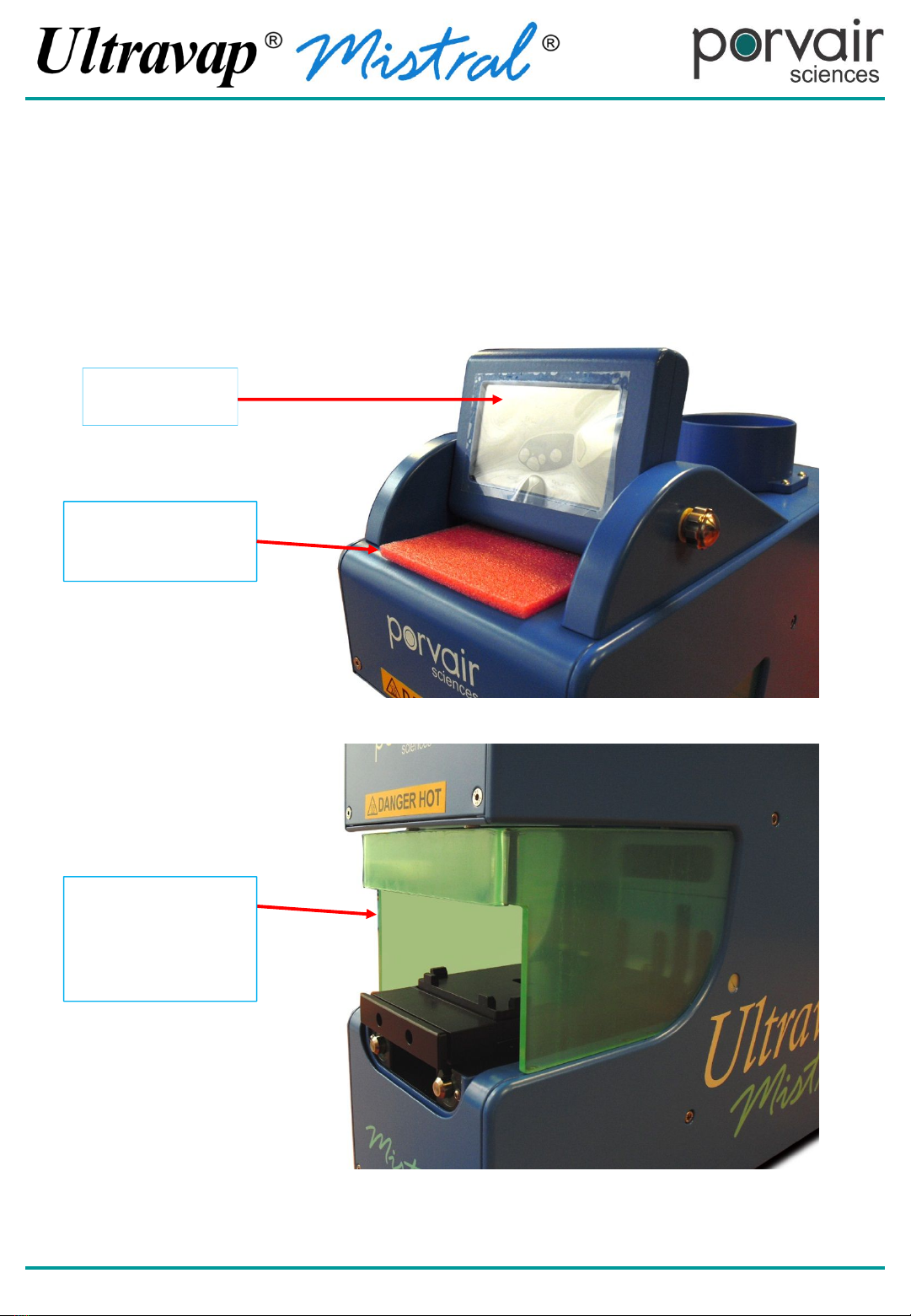

The Ultravap Mistral has been developed to be an automation friendly, compact, stand alone

blow down sample concentrator, to allow evaporation of solvents, from microplates in minutes,

rather than hours. This instrument encourages integration by incorporating a shuttle style plate

carrier.

The instrument eliminates the traditional “bottleneck” of solvent evaporation prior to analysis or

reconstitution in buffer. It has been designed to be used with ANSI/SBS format 96 well plates

(conforming to the standards mentioned on the next page). The instrument when fitted with

compatible straight or spiral needle heads, which offers improved drying efficiency, can be used

with 96 well plates. All evaporator heads are easily interchangeable. The device will

accommodate either 96 or 384 well plates, with straight needles, or spiralled needles (96 plate

only).

The Ultravap Mistral blows heated gas (typically Nitrogen) into the wells and accommodates both

deep and shallow well plates. The platform containing the well plates, is programmable in

elevation to suit well plate dimensions and dry-down protocol.

The concentrator has been configured to be simple to install, operate and maintain. Installation

requires connection to a gas supply of nitrogen or clean dry air and a suitable electrical supply.

Safe operation is ensured as the CE marked unit fits into fume cupboards, or may be integrated

into a dedicated fume extraction unit.