POST MATERIAL HANDLING

21 Stone Castle Road, Rock Tavern, NY 12575 (845) 200-3355 www.posthoist.com

DRUM CONDITIONER OPERATION

(Using Control Panel)

1. Connect power to the machine using the

120VAC watertight connector.

2. Connect air pressure to the machine.

3. Turn the electrical DISCONNECT switch to

the ON position.

4. Ensure the rear caster wheels on the

machine are locked.

5. Place the drum to be conditioned in

position in front of the machine.

6. Press the RESET button. The RESET

button will remain illuminated when the

safety relay is satisfied and the conditioner

is ready to run.

7. Press the RUN DRUM CONDITION

CYCLE button. The drum condition

sequence will proceed in the following

steps:

a. The drum conditioner will open and

zero the arm encoder.

b. The arms will carefully close as the

drum conditioner measures the

diameter of the drum at the FEEL SETPOINT in PSI. The drum should not

be compressed. If the arms do not close increase the FEEL PRESSURE

setpoint.

c. The drum conditioner opens slightly before increasing to the CRUSH

SEPOINT in PSI.

d. The drum conditioner closes the arms until the CRUSH DISTANCE is

reached, the CRUSH TIMEOUT time elapses, or the MIN ARM SPAN is

reached.

e. The arms are held stationary for the CRUSH HOLD TIME in seconds.

f. The drum conditioner opens the arms to the approximate diameter of the

drum.

g. Steps d –f are repeated for the NUMBER CYCLES setting on the DRUM

CONDITION SETTINGS SCREEN.

h. Once the cycle is complete the arms open slightly wider than the drum and

cylinder pressure is reduced to the holding pressure. The holding pressure

is linearly scaled from the maximum and minimum DRUM SIZE and DRUM

HOLDING PRESSURE settings on the HMI.

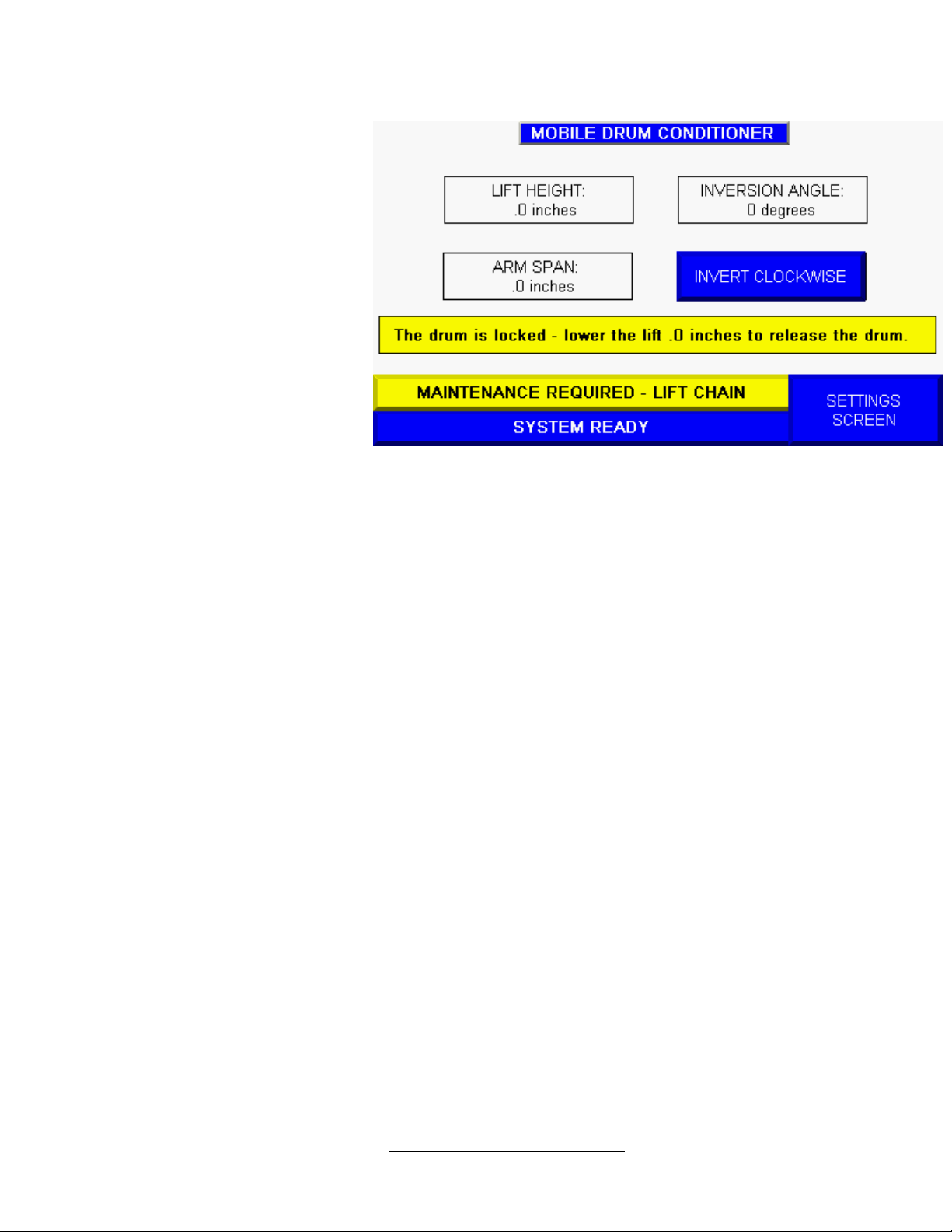

i. The arms close securely on the drum and it is ready to be lifted as

necessary to unload. “The lift is firmly holding the drum” is displayed on

the MAIN SCREEN of the HMI.

8. Rotate the LIFT selector switch to the RAISE position. The lift begins to raise the

drum.

a. When the drum is lifted above the MAX DROP DISTANCE in inches the

arms are locked. “The drum is locked – lower the lift X.X inches to release

the drum” is displayed on the MAIN SCREEN.