3

INS-1500/INS-2000 (EU) • 5403653 • REV F • 5/23

Contents

Safety Guidelines...............................................................................................................................................................................................4

Important Notice to Users........................................................................................................................................................................4

Unpacking................................................................................................................................................................................................4

General Safety Information......................................................................................................................................................................4

System Overview...............................................................................................................................................................................................6

Key Terms................................................................................................................................................................................................6

IntelliGen™Controller..............................................................................................................................................................................6

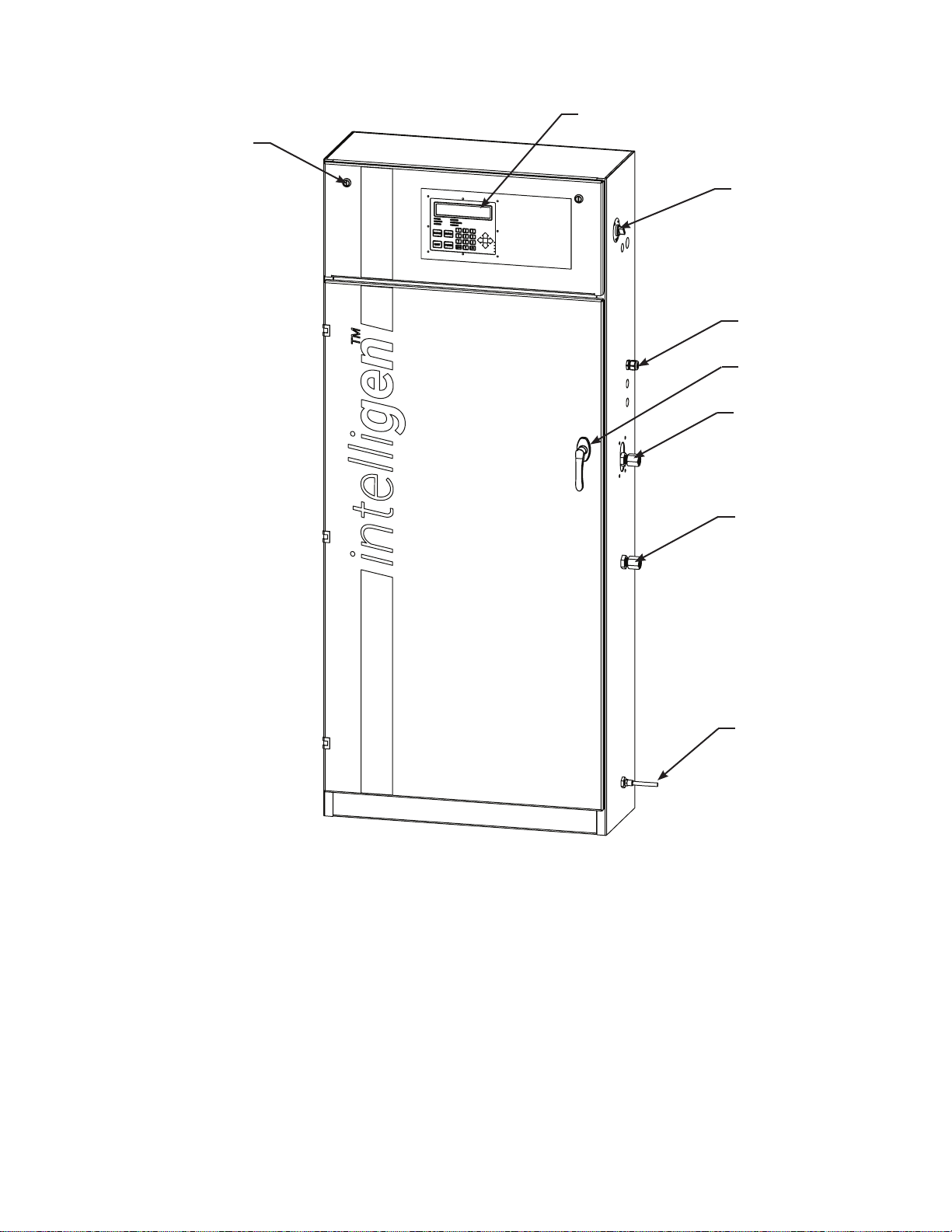

INS-1500/2000 (EU) Exterior View..................................................................................................................................................................7

INS-1500/2000 (EU) Interior View...................................................................................................................................................................8

INS-1500/2000 (EU) Nitrogen Tank View........................................................................................................................................................9

INS-1500/2000 (EU) Air Compressor View......................................................................................................................................................10

IntelliGen™Display ...........................................................................................................................................................................................11

Installation of the Nitrogen Generator...............................................................................................................................................................12

Wiring of the Nitrogen Generator......................................................................................................................................................................16

Air Compressor (380-415 VAC Three Phase) .........................................................................................................................................16

Compressor Sensor Wire..........................................................................................................................................................................17

Air Tank Blow-Down Located on the Bottom of the Tank Mounted Air Compressor (220 VAC).........................................................18

Nitrogen Cabinet (180-220 VAC)............................................................................................................................................................18

Internet Connectivity, PLINK, and BMS (Optional)...............................................................................................................................19

Nitrogen Generator Operation ...........................................................................................................................................................................20

Nitrogen Functionality Test ..............................................................................................................................................................................22

Filling the Sprinkler System and Purging..........................................................................................................................................................23

Purging with IntelliPurge®Nitrogen Purge Valve (INS-PV).............................................................................................................................24

Purging with Potter Nitrogen Purge Valve (NGP-SPV) ....................................................................................................................................25

IntelliView™Dashboard Internet Connectivity..................................................................................................................................................26

IntelliPurge®Wiring and Networking................................................................................................................................................................27

Maintenance and Part Replacements.................................................................................................................................................................28

Standard Maintenance........................................................................................................................................................................................29

Compressor Air Intake Filters..................................................................................................................................................................30

Air Tank Blow-down Strainer..................................................................................................................................................................31

Lubricated Air Compressor Oil................................................................................................................................................................31

Filter Elements.........................................................................................................................................................................................32

Resetting Maintenance Alert and Checking for Leaks ............................................................................................................................34

Air Compressor Replacement............................................................................................................................................................................35

Nitrogen Membrane Replacement.....................................................................................................................................................................35

Maintenance Alerts and Actions ........................................................................................................................................................................36

Trouble Alerts and Probable Causes..................................................................................................................................................................37

Troubleshooting.................................................................................................................................................................................................39

Leak on Sprinkler System or Nitrogen Generator ...................................................................................................................................39

Nitrogen Flow Rate and Nitrogen Purity Test .........................................................................................................................................39

Normal Operating Parameters of the INS-1500/2000 (EU) ..............................................................................................................................40

Nitrogen Generator Leak Detection System......................................................................................................................................................41

To Change the Leak Rate Warning Set Point.............................................................................................................................................42

To Change Sprinkler System Size..............................................................................................................................................................42

INS-1500/2000 (EU) Cabinet Dimensional Drawings......................................................................................................................................43

INS-1500/2000 (EU) Compressor Dimensional Drawings ...............................................................................................................................44

INS-1500/2000 (EU) Air Tank Dimensional Drawings.....................................................................................................................................45

INS-1500/2000 (EU) Piping Instrumentation Diagram.....................................................................................................................................46

Wiring Diagrams................................................................................................................................................................................................47

INS-1500/2000/2500 (EU) 380-415VAC Three Phase............................................................................................................................47

Menu Trees.........................................................................................................................................................................................................48

Menu Tree 1.............................................................................................................................................................................................48

Menu Tree 2.............................................................................................................................................................................................49

Menu Tree 3.............................................................................................................................................................................................50

Menu Tree 4.............................................................................................................................................................................................51

Menu Tree 5.............................................................................................................................................................................................52

Menu Tree 6.............................................................................................................................................................................................53

Menu Tree 7.............................................................................................................................................................................................54