Supplied By www.heating spares.co Tel. 0161 620 6677

2Contents Part No. 900/9350/1

Contents - Page 2

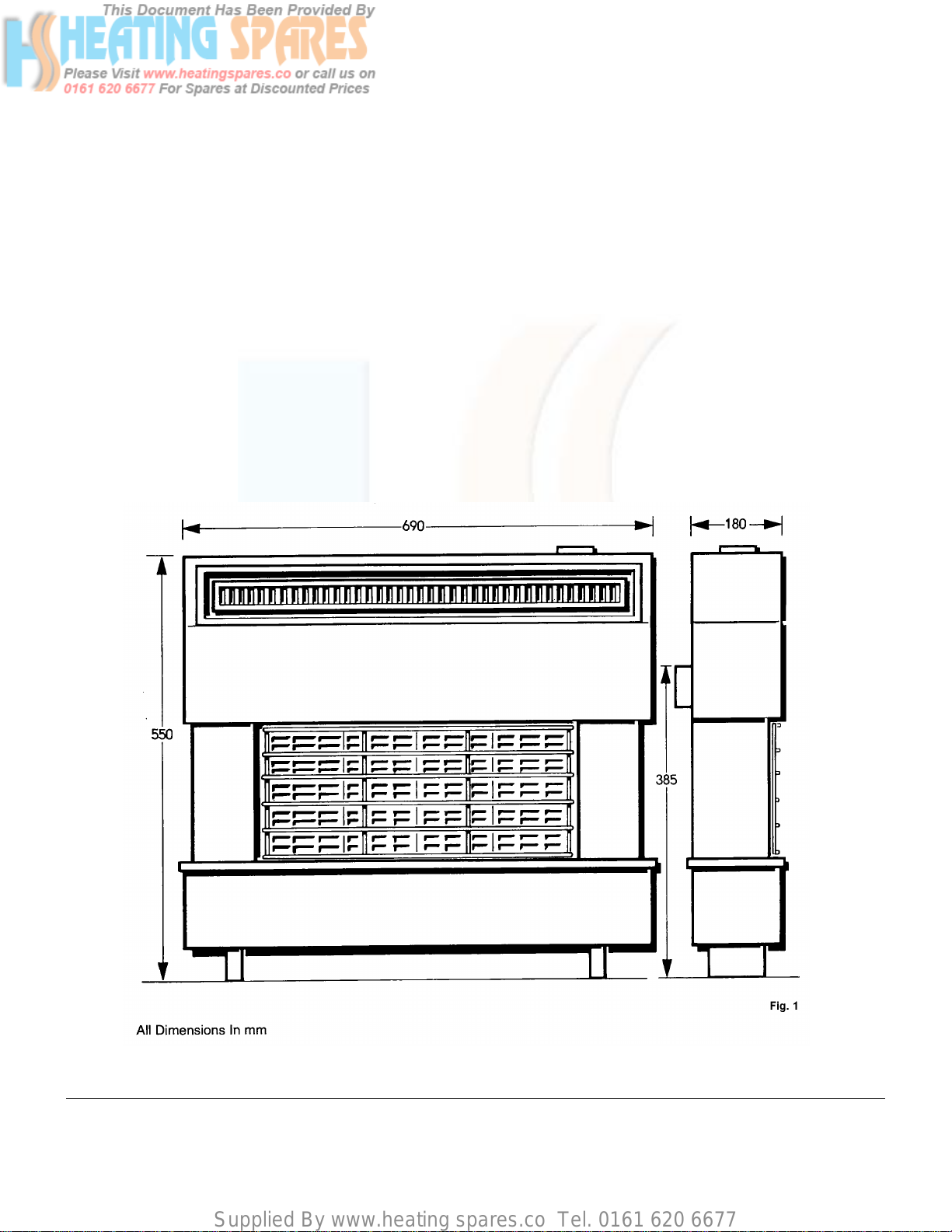

1. TECHNICAL DATA.................................................................................................................................................. 3

2. GENERAL................................................................................................................................................................ 4

3. INSTALLATION REQUIREMENTS......................................................................................................................... 4

3.1 Fire location....................................................................................................................................................... 4

3.2 Check The Chimney.......................................................................................................................................... 4

3.3 Combustible Wall Cladding................................................................................................................................5

3.4 Fireplace Opening .............................................................................................................................................5

3.5 Fire Surround & Shelves....................................................................................................................................5

3.6 Spigot & Spigot Extension................................................................................................................................. 6

3.7 Pre-Cast Flue.....................................................................................................................................................6

4. INSTALLATION....................................................................................................................................................... 6

4.1 Unpack the Fire .................................................................................................................................................6

4.2 Pre-Cast Flue.....................................................................................................................................................6

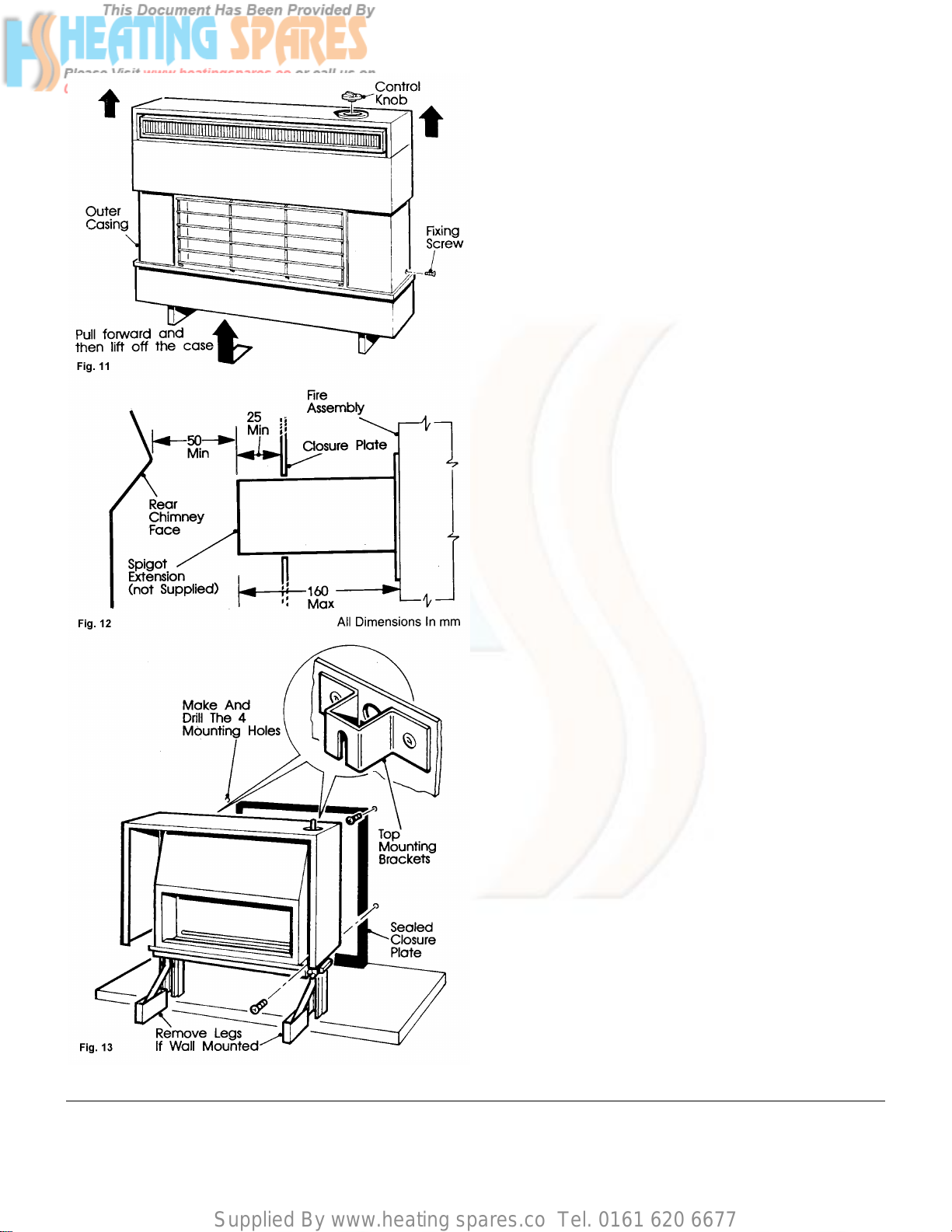

4.3 Closure Plate - Wall Mounted............................................................................................................................ 7

4.4 Closure Plate - Hearth Mounted........................................................................................................................ 7

4.5 Spigot Restrictor................................................................................................................................................ 7

4.6 Dis-assemble The Fire.......................................................................................................................................8

4.7 Mounting The Fire..............................................................................................................................................8

4.8 Prepare The Fire Connection ............................................................................................................................8

4.8.1 Gas Connection........................................................................................................................................ 9

5. CHECK GAS PRESSURE & OPERATION OF FIRE.............................................................................................. 9

6. TEST for SPILLAGE ............................................................................................................................................. 10

7. COMPLETE THE INSTALLATION........................................................................................................................ 11

8. CUSTOMER INFORMATION................................................................................................................................. 11

9. SERVICING & REPLACEMENT OF PARTS ........................................................................................................ 12

9.1 General Access ...............................................................................................................................................12

9.2 Burner and Electrode.......................................................................................................................................13

9.2.1 Electrode

9.2.2 Burner..................................................................................................................................................... 13

9.3 Gas Tap, Piezo And Injectors.......................................................................................................................... 14

9.3.1 Piezo....................................................................................................................................................... 14

9.3.2 Injectors.................................................................................................................................................. 14

10 SHORTLISTOFSPARES....................................................................................................................................... 15