1. General View ......................................................................................... 3

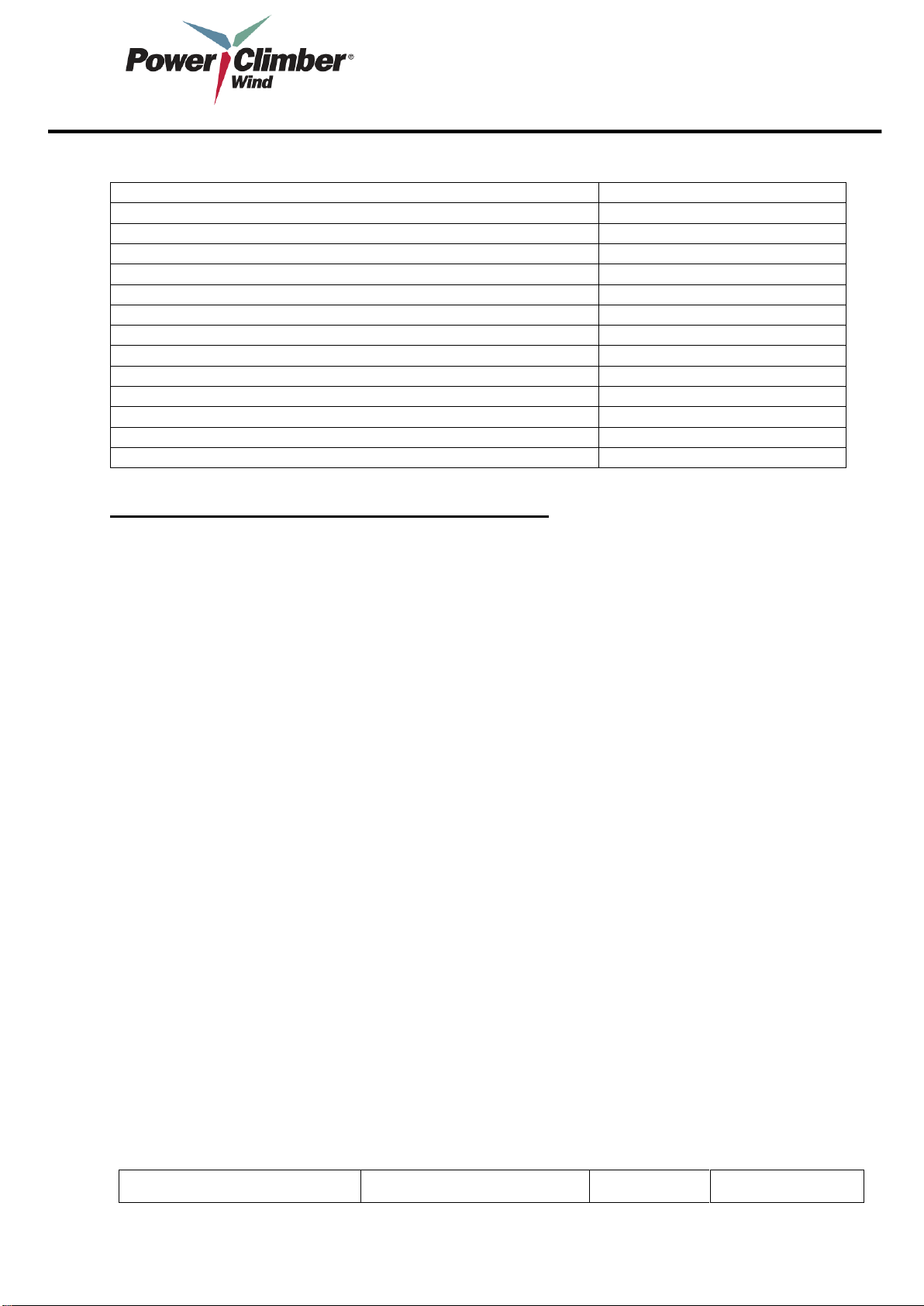

2. Specifications........................................................................................ 3

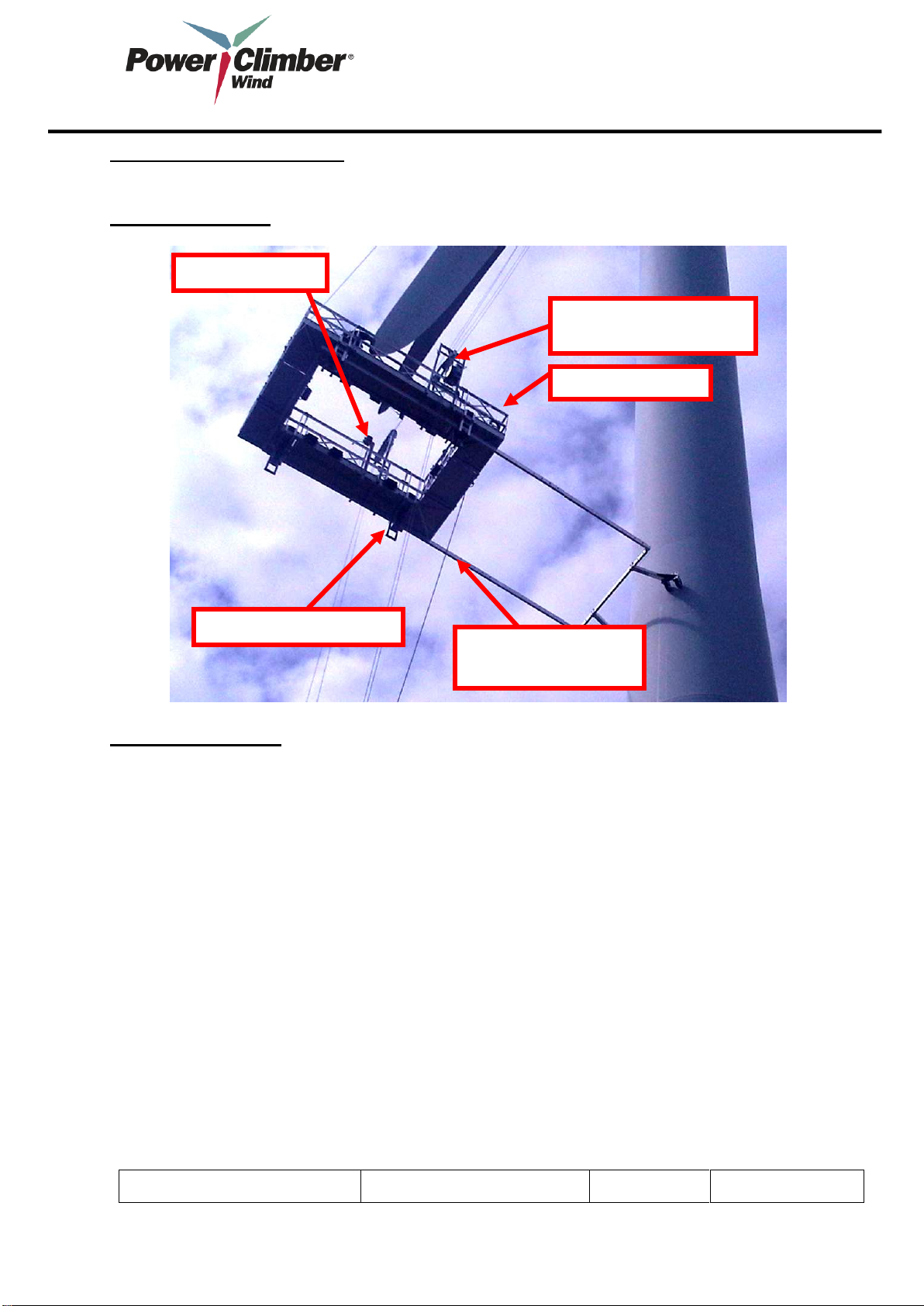

3. Rigging of the Steel Wires at the Nacelle............................................ 4

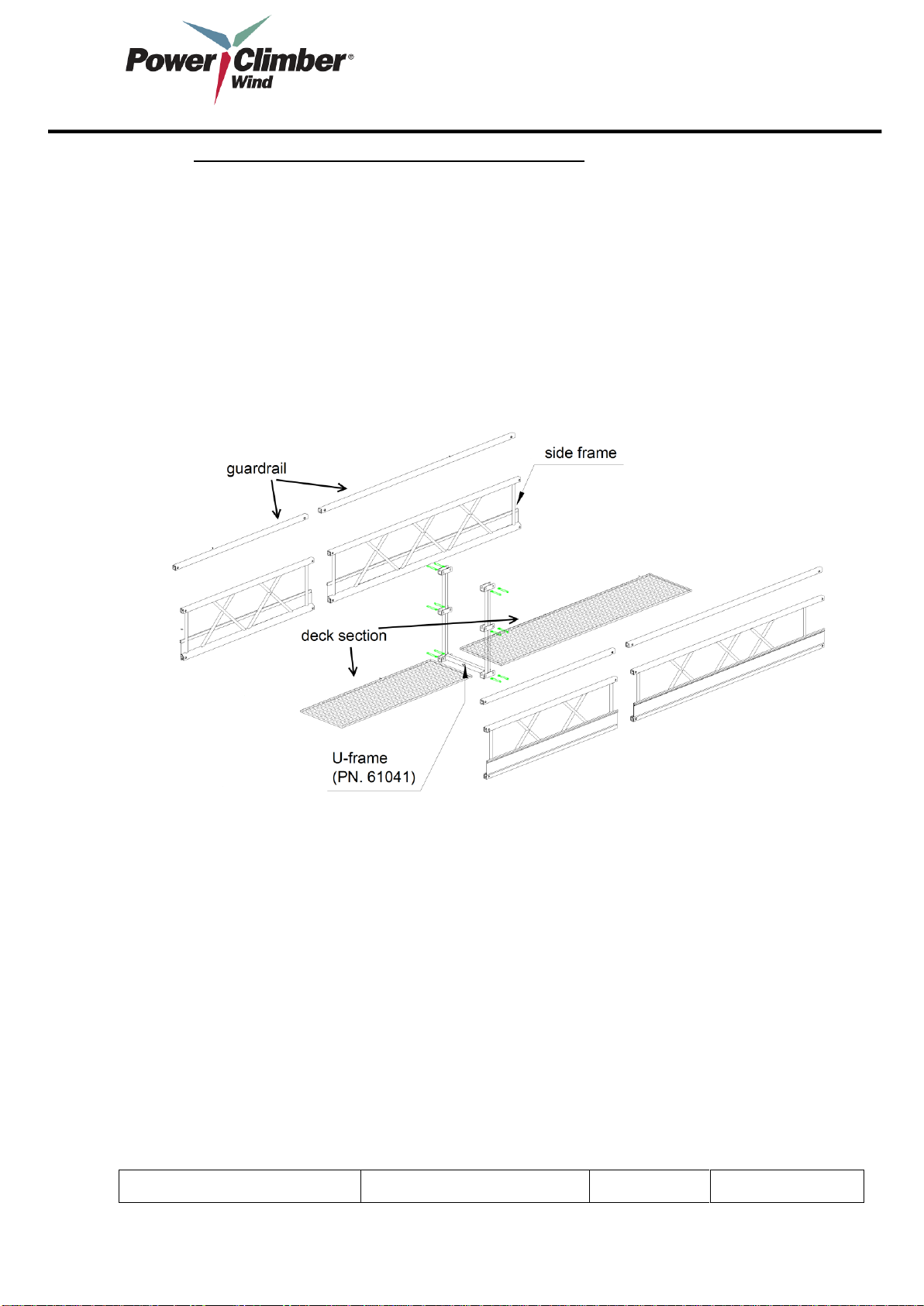

4. Assembly of the BAP 360°.................................................................... 5

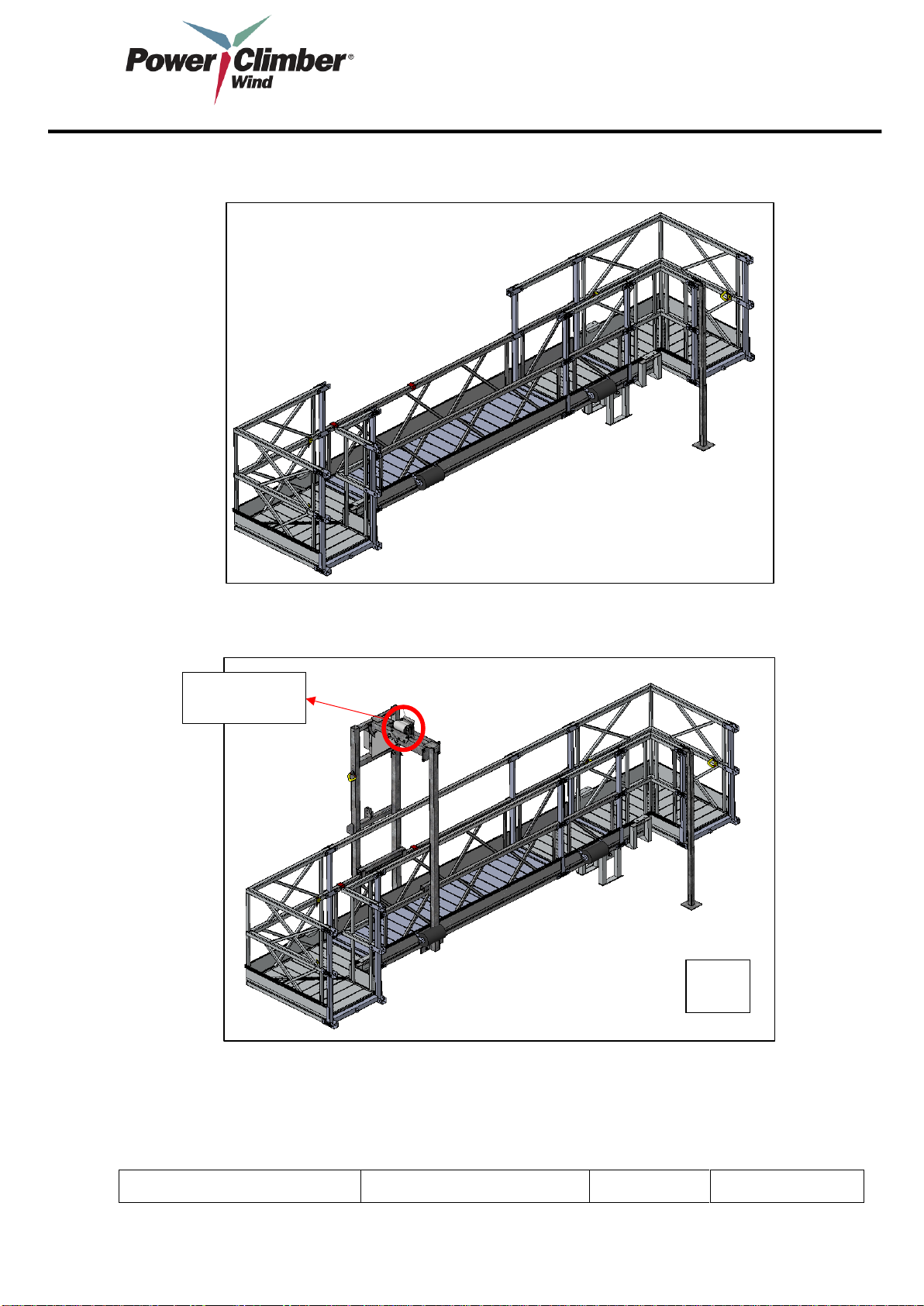

5. Overview of Assembled Platform ...................................................... 21

6. Operation of the Blade Access Platform........................................... 23

7. Instructions & Precautions Before Starting and During Operation. 25

8. Hoist Specifications and Features..................................................... 28

9. Reeving of Steel Wires ....................................................................... 29

10. Maintenance...................................................................................... 31

11. Trouble shooting............................................................................... 32

12. Safety Features ................................................................................. 33

13. Steel Wire Specs and Inspection Criteria........................................ 35

14. General Caution And Precautions ................................................... 36

15. Daily Test........................................................................................... 37

Manufacturer:

Power Climber Wind b.v.b.a,

Satenrozen 7,

B-2550

Kontich BELGIUM

Phone: +32-3-451 05 00

Fax ; +32-3-451 05 01

Email: info@PowerClimber.be