USING THE SAW

GENERAL INSTRUCTIONS

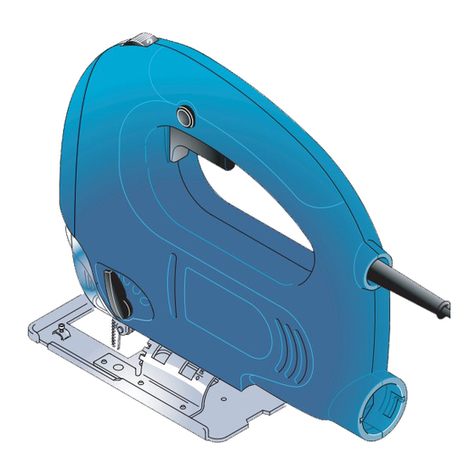

Figs. 3.1-3.6

Fig. 3.1 The material to be sawn must not be thicker than

the maximum saw depth.

Fig. 3.2 Before use, check the saw blade for damage and

replace it if necessary.

Fig. 3.3 Make sure that the piece of work to be sawn is

well clamped down.

Fig. 3.4 Make sure that the piece of work to be sawn is

clean.

Fig. 3.5 Make sure that there is enough space below the

piece of work to be sawn, so that the saw does not come

into contact with other surfaces.

Fig. 3.6 Make sure that the material to be sawn is free of

nails and screws and the like.

INSTALLING THE SAW BLADE

Figs. 2 and 4.1-4.4

Make sure that the power cord is not plugged into

the mains.

To install the saw blade, loosen the Allen screw (A) using

the Allen key (C) (by turning it anticlockwise). Place the

saw blade (B) in the blade holder from underneath with

the saw teeth pointing forwards. Tighten the Allen screw

(A) using the Allen key (C) (by turning it clockwise).

Check that the saw blade is installed at right angles to the

base plate (see Fig.4.4).

ADJUSTING THE BASE PLATE

Figs. 2 and 5.1-5.5

Make sure that the power cord is not plugged into

the mains.

To install the base plate (D) the Allen screws (E) must be

unscrewed (anticlockwise). The base plate (D) can now

be moved backwards. Now the saw angle required can

be set, which can be read (F). After setting the correct

angle the base plate (D) must be moved forwards again

into the interlocking position. Then the Allen screw (E) is

screwed tight again.

For saw angles that are different from the standard

adjustable angles, the base plate does not have to be

moved forward again into the locking position. After

setting the correct angle, make sure that the Allen

screws (E) are screwed tight.

USE OF THE PARALLEL GUIDE

Figs. 6.1-6.4

Make sure that the power cord is not plugged into

the mains.

The parallel guide (H) can be mounted as an aid to sawing

a straight strip of wood, for example.

Unscrew the Allen screws (G) (anticlockwise). Now the

parallel guide can be set in the base plate to the distance

required. See the calibration marks on the parallel guide.

Finally tighten the Allen screws (G) (clockwise) using the

Allen key (C).

REGULATING THE PENDULUM ACTION

Fig. 7

For hard materials always choose a low pendulum

action.

Installation hints – choice of saw blade

Saw blade Type of material

Rough Wood

Medium Wood

Fine Plastics, aluminium, steel

Very fine Sawing curves (wood)

Pendulum action* Accuracy

2, 4, 6 +

2, 4 ++

2 +++

2 +++

*Continuously variable

SETTING THE PENDULUM ACTION

Fig. 3

To get the optimum result when sawing, you must set up

how the teeth of the saw blade must cut into the

material. You do this by adjusting the pendulum action.

•Soft material (wood, plastics, etc.): choose pendulum

action II or III. For sawing shiny materials choose

pendulum action 0 or I.

•Medium hard materials (hardwood, aluminium, etc.):

choose the pendulum action you need. For thin

materials use pendulum action 0 or 1 if you work

with rasps or knives.

•Hard materials (steel etc.): choose pendulum action 0.

•Curved saw-cut: choose pendulum action 0.

The pendulum action can be chosen while the jigsaw is

turned on.

OPERATING

Figs. 8.1-8.2

Switch 1 turns the machine on. In addition, for longer

saw-cuts the button 2 can be used: this locks switch 1 in

the ON position. To switch the machine off, press

button 2 again.

ADJUSTING THE STROKE RATE

Fig. 9

The stroke rate required can be set with the aid of the

revolution regulator (I).

Powercraft 9

•Never use the equipment where it could cause a fire

or an explosion. Keep it out of the neighbourhood of

flammable liquids and gases, as electric equipment

can cause sparks that can lead to a fire.

• Keep children and other people away when using the

equipment. If you become diverted you can lose

control of the equipment.

2. Electrical safety

• The plug on the power cord must fit perfectly into

the wall socket. The plug must never be changed in

any way. Do not plug the tool into any socket

adapters. Unchanged plugs and suitable sockets

reduce the risk of electric shock.

• Avoid bodily contact with earthed surfaces such as

metal pipes, conduits, central heating pipes and

radiators and refrigerators. The risk of an electric

shock is higher when your body is earthed.

• Never expose the equipment to rain or damp.

Water penetration into electric equipment

increases the risk of electric shocks.

• Never use the power cord to lift the equipment or to

hang it up, or to pull the plug out of the socket. Make

sure that the power cord does not lie on or come

into contact with and keep it away from heat, oil and

all moving parts. Damaged and tangled power cords

increase the risk of an electric shock.

• When you use the equipment in the open air, only

use an extension cable that is approved for outside

use: in this way you reduce the risk of an electric

shock.

3. Personal safety

• Be attentive, pay attention to what you are doing and

use your common sense when working with this

equipment. Never use tools when you have been

drinking alcohol or taken medicines. One moment of

inattention can lead to serious injury.

• When using this machine always wear safety

equipment and safety glasses. Depending on the

circumstances you can also lessen the risk of

accidents by wearing a facemask, sturdy work shoes

with non-slip soles, a safety helmet and ear

protection.

• Prevent the machine being switched on by mistake:

always check that the ON/OFF switch is in the OFF

position before plugging the equipment into the

mains socket. If you carry the machine with your

finger on the ON/OFF switch or connect it to the

mains when the switch is in the ON position, this can

result in accidents.

• Remove all tools and screw keys used for setting up

or adjusting the machine before you switch on the

equipment. A tool or key that comes into contact

with a rotating part can cause accidents.

• Do not overestimate yourself. Make sure that you

stand firmly and that you keep your balance at all

times. In this way you can keep the equipment under

control in unexpected situations.

• Wear suitable clothing. Do not wear loose clothing

or jewellery. Keep your hair, clothes and gloves away

from moving parts. Loose clothing, jewellery and

long hair can become trapped by moving parts.

• When a dust suction and dust catching installation

are installed, check that these are connected and

used in the right way. Use of these installations leads

to less inconvenience caused by dust.

4. Handle and use electrical tools carefully.

• Make sure that the equipment is not overloaded and

use it only for work for which it is intended. Keep

within the stated performance limits.

• Never use electric equipment that has a defective

switch. Electric tools that can no longer be switched

on and off are dangerous and must be repaired.

• Unplug the equipment from the mains before you

adjust it, install accessories or put it aside. In this way

you can prevent the machine being started

accidentally.

• Keep electric equipment that is not in use out of the

reach of children. Never allow the equipment to be

used by people who are not familiar with it or who

have not read the instructions for use. Electric

equipment can be dangerous in the hands of

inexperienced people.

• Make sure that the equipment is well maintained.

Regularly check that all moving parts move freely and

do not stick, and check for any broken or damaged

parts that can prevent the equipment working

properly. Have any damaged parts repaired before

using the equipment again. Many accidents are

caused by insufficient maintenance of electrical

equipment.

• Make sure that the saw blades are sharp and clean.

Well-maintained saws with sharp edges stick less and

are easier to guide.

• Always use electrical equipment according to the

hints and directions for use for the equipment

concerned. Take into account the circumstances and

the task to be carried out. Use of electrical

equipment for other purposes than those it is meant

for can lead to dangerous situations.

5. Maintenance and repairs

• Only have this equipment repaired by skilled

personnel using original parts. In this way you can be

sure that the safety of the equipment is guaranteed.

• If the power cord needs to be replaced, have this

done by the manufacturer or a recognised

representative. In this way you can be sure that the

safety of the equipment is guaranteed.

USES

With this jigsaw you can saw pieces of various materials

(wood, aluminium, plastics, metal, etc.) very accurately

and into any form. The maximum thickness of the

material to be sawn is 70mm (for wood).

All other applications (such as stationary use, for

example) are expressly forbidden.

The maximum saw depth of 70mm is only possible with

an extra long saw blade.

For hard materials always choose a small orbital

movement.

8Powercraft