POWER ELECTRONICS V5 Operation Instructions V5IM01BI

9

ENGLISH

1. MOUNTING AND WIRING

1.1 ENVIRONMENTAL CONDITIONS

The maximum ambient/working temperature for the V5 is 45ºC. The V5 can be operated in a higher ambient

temperature of up to 50ºC by de-rating the soft starter by 2% for every degree over 45ºC.

1.2 IEC PROTECTION

The V5 soft starter ingress protection is IP20. This means that the soft starter is protected against finger contact with

hazardous or moving parts inside the enclosure, and protection of against ingress of foreign objects with a diameter

greater than 12mm.

1.3 MOUNTING

The V5 soft starter is designed for vertical mounting. Input bus bars are located in the top and motor bus bars must

be connected at the bottom, except for models V50009 to V50090 where both, input and output must be connected at

the bottom.

To improve heat dissipation, it is recommended to mount the soft starter on a metal gear plate.

When installed within a cabinet, proper ventilation is to be provided. A minimum of 40mm side clearance and 150mm

top and bottom distance is to be kept between soft starters and or side of the enclosure.

Do not install V5 above any heat source, unless heat airflow is forced out of the cabinet.

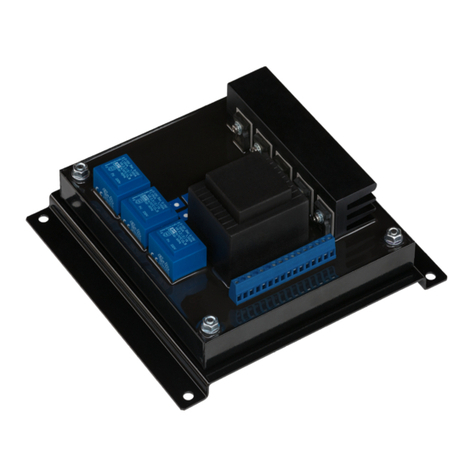

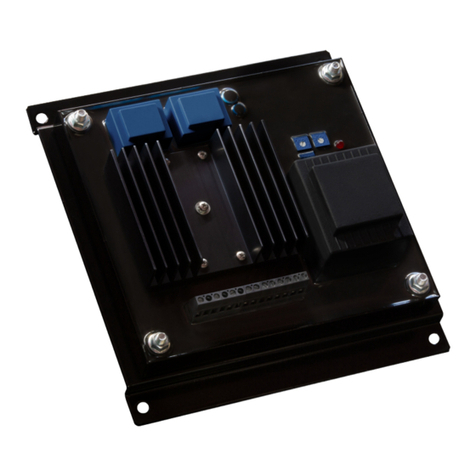

Figure 1. Vertical mounting.

1.4 POWER LOSS DISSIPATION

The V5 has a power loss of 3 watts per amp. For example this means that a V50210 has a power loss of 630 watts at

full load.

1. 5 WIRING CONFIGURATION

Most electrical wiring regulations require a mains isolator on solid state equipment. The V5 falls in to this category.

This is to ensure there is an air break in the circuit as semiconductors cannot be relied upon to be safe isolation.

There are many choices, the most common are thermal magnetic protection with a trip coil in conjunction with a

contactor.

Magnetic protection is required to protect the V5 from damage due in the event of a short circuit within the V5 or on

the output cabling or motor. When faster protection is desired, semiconductor fuses are recommended. The fuses

should be mounted as close to the V5 as possible. Power factor correction capacitors must not be connected after

the fuses or on the output of the V5.