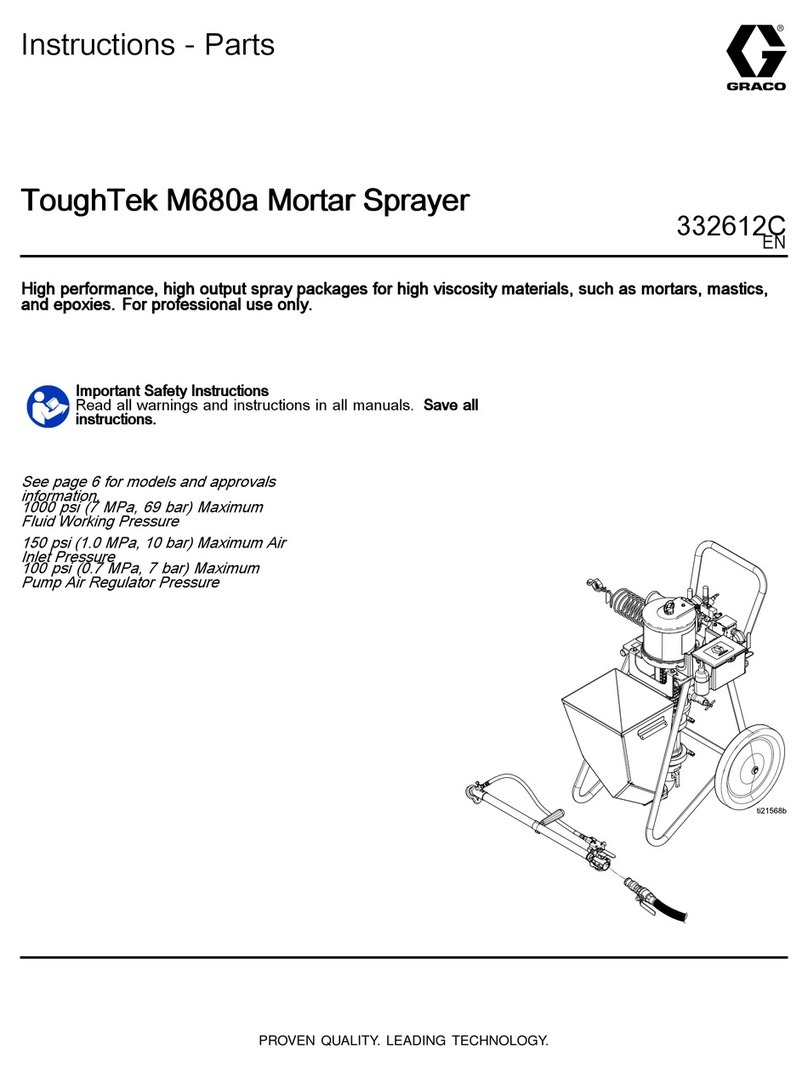

Graco 232833 User manual

Other Graco Paint Sprayer manuals

Graco

Graco RATIO BULLDOG 238-253 User manual

Graco

Graco 262927 User manual

Graco

Graco Reactor H-40 Elite Instruction Manual

Graco

Graco PRO 309291 User manual

Graco

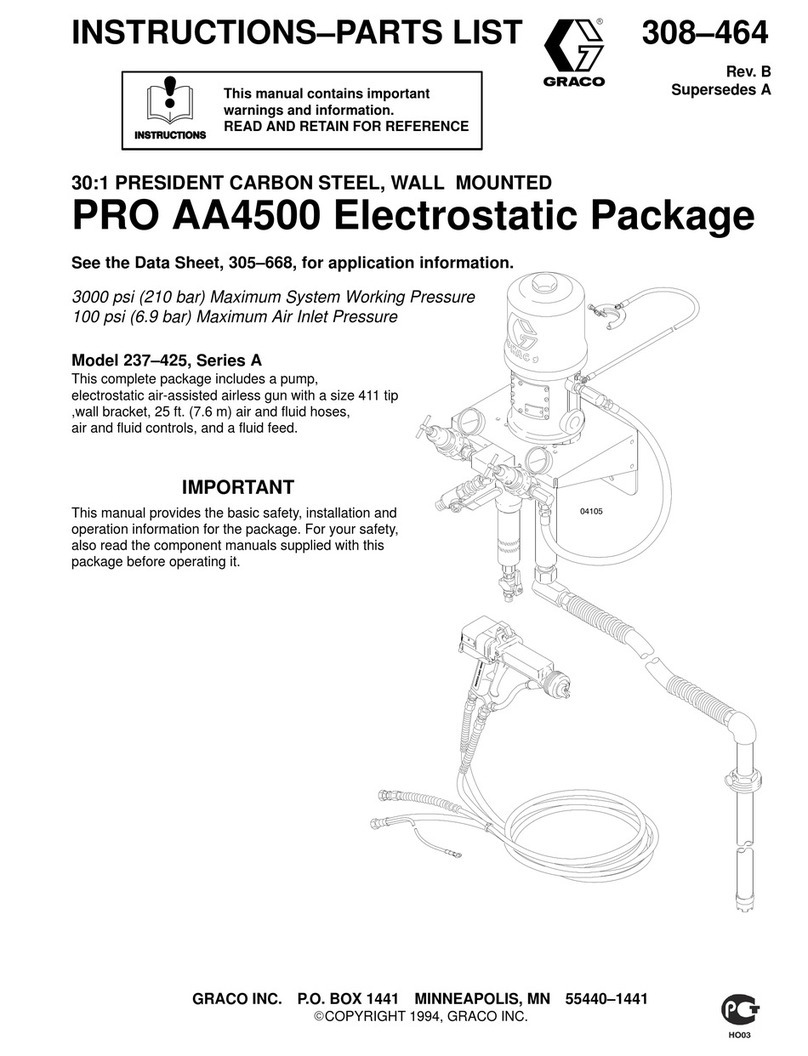

Graco 237-425 Operation manual

Graco

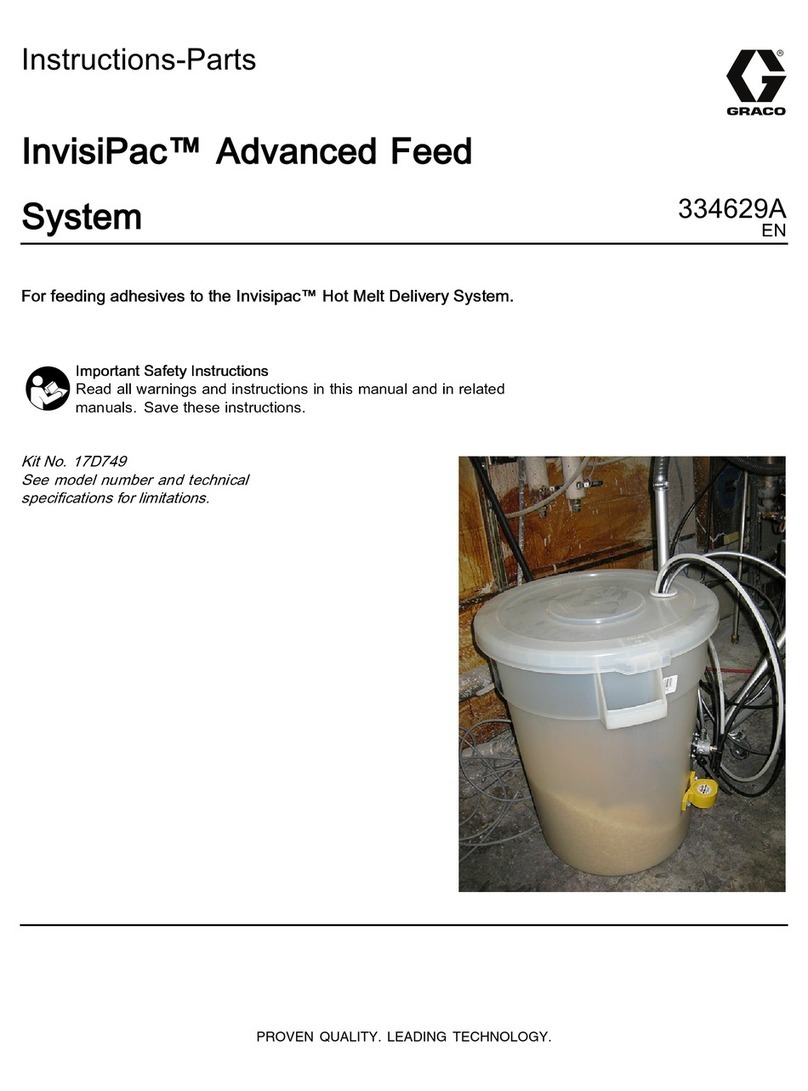

Graco InvisiPac AFS 17D749 Parts list manual

Graco

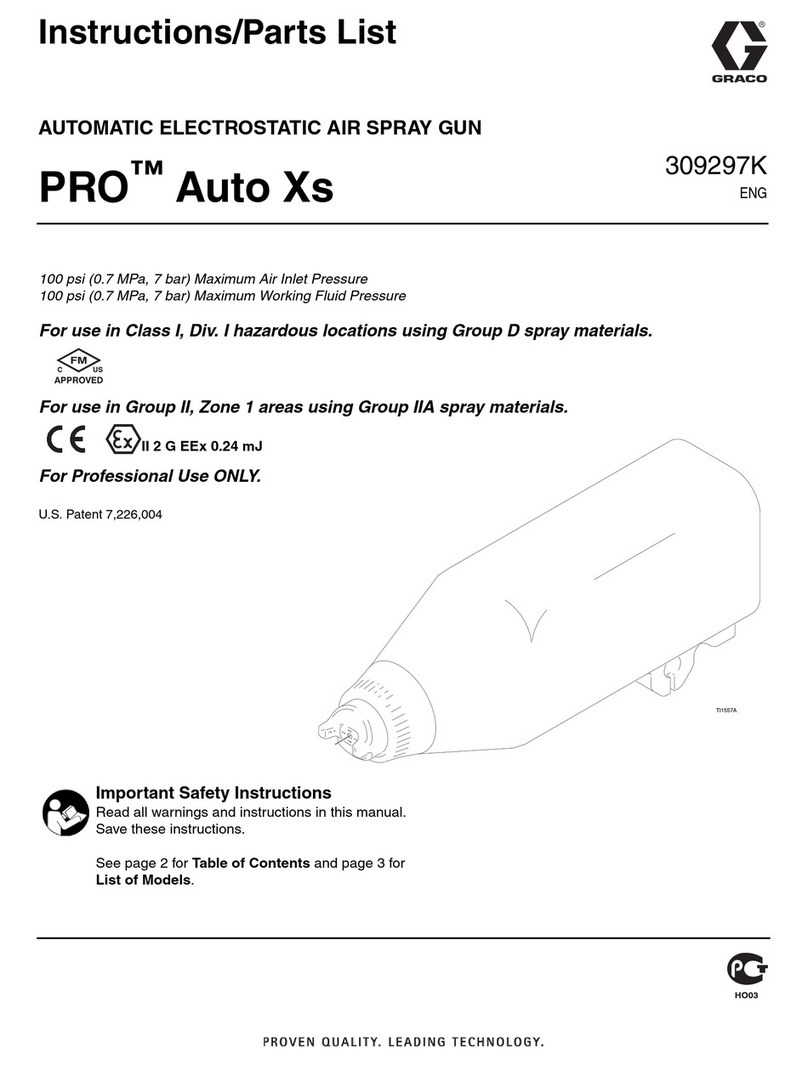

Graco PRO Auto Xs Series Operation manual

Graco

Graco FT500 Use and care manual

Graco

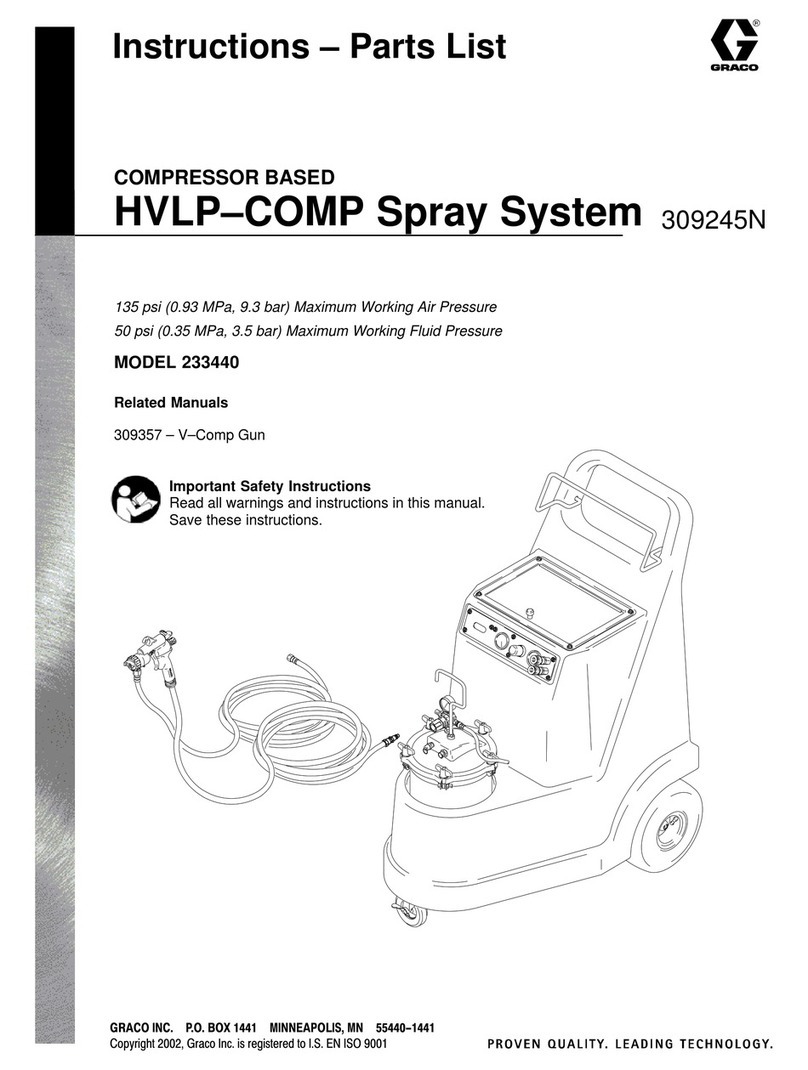

Graco 233440 Operation manual

Graco

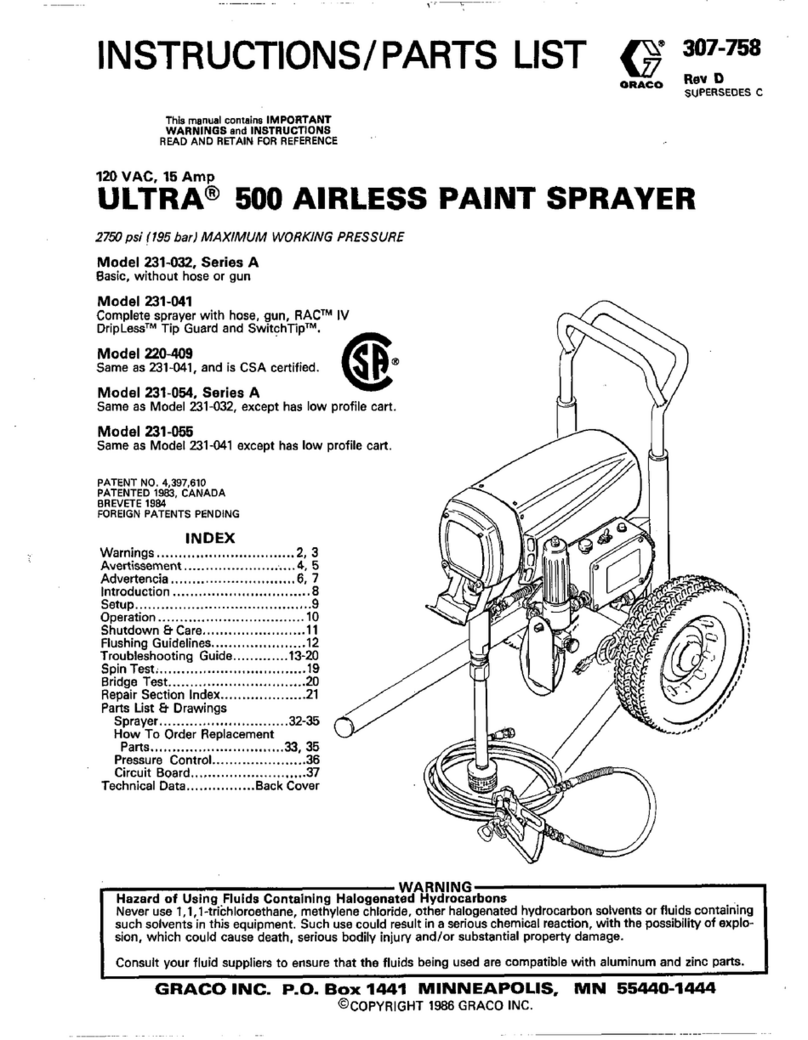

Graco ULTRA 500 Operation manual

Graco

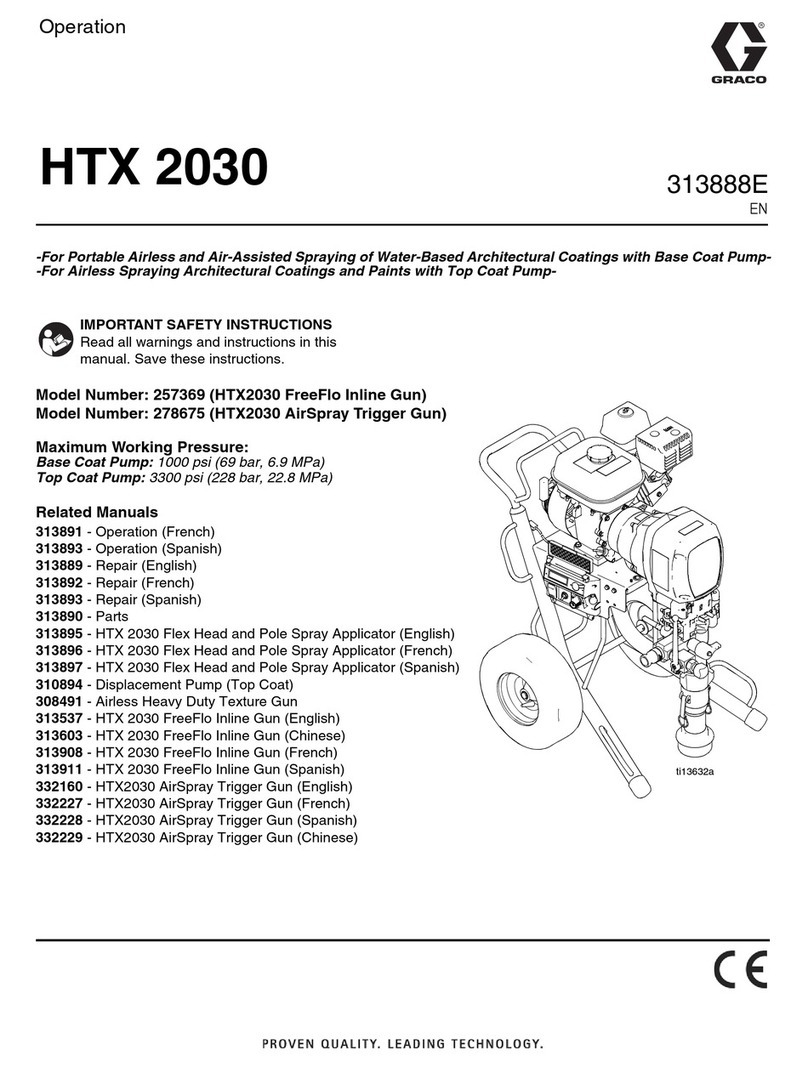

Graco HTX 2030 User manual

Graco

Graco LineLazer II 3900 User manual

Graco

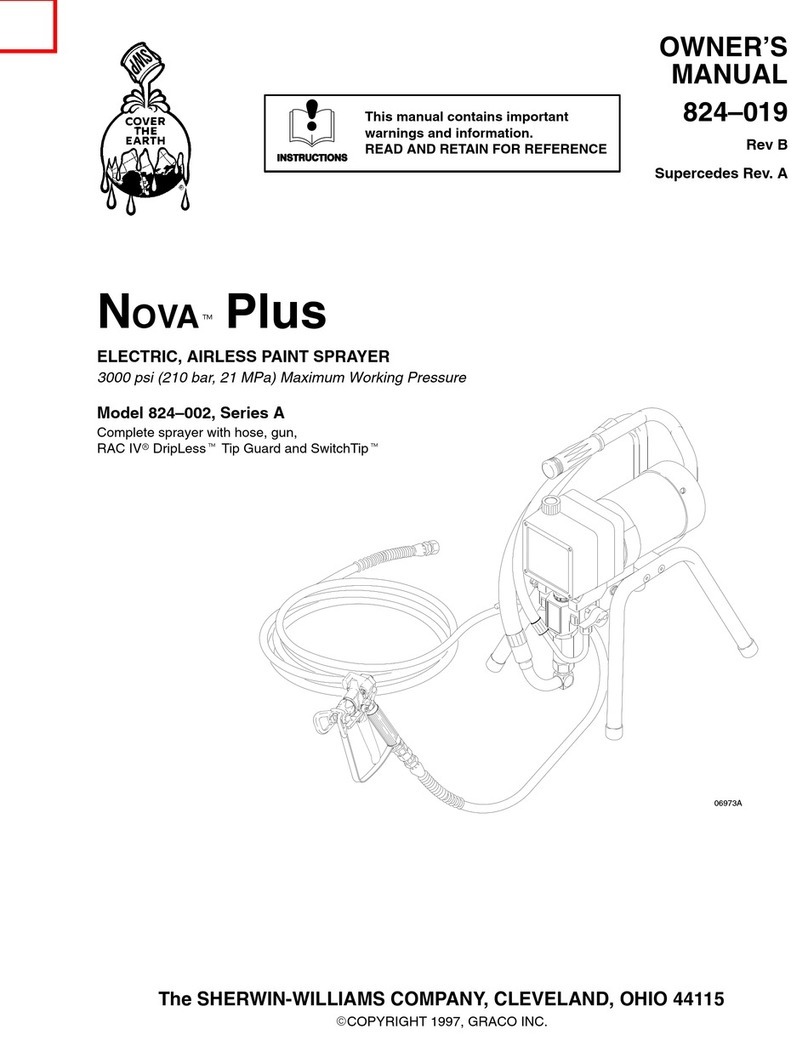

Graco NOVA Plus l 824-002 User manual

Graco

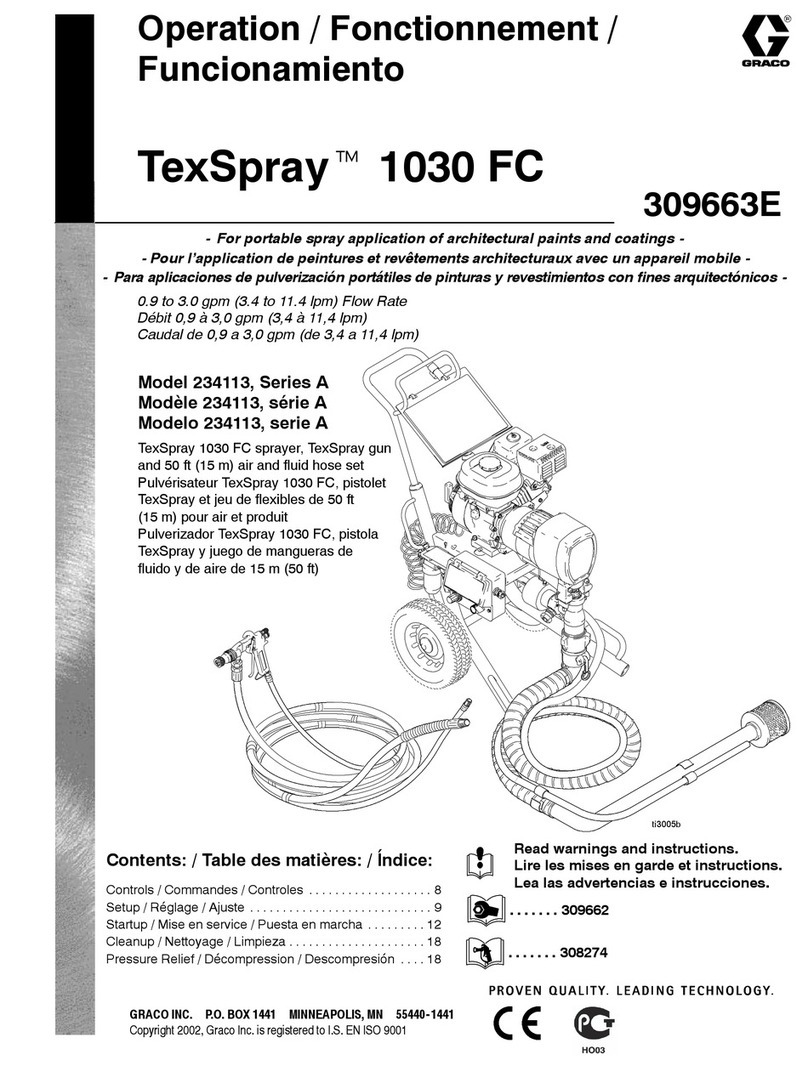

Graco TexSpray 1030 FC User manual

Graco

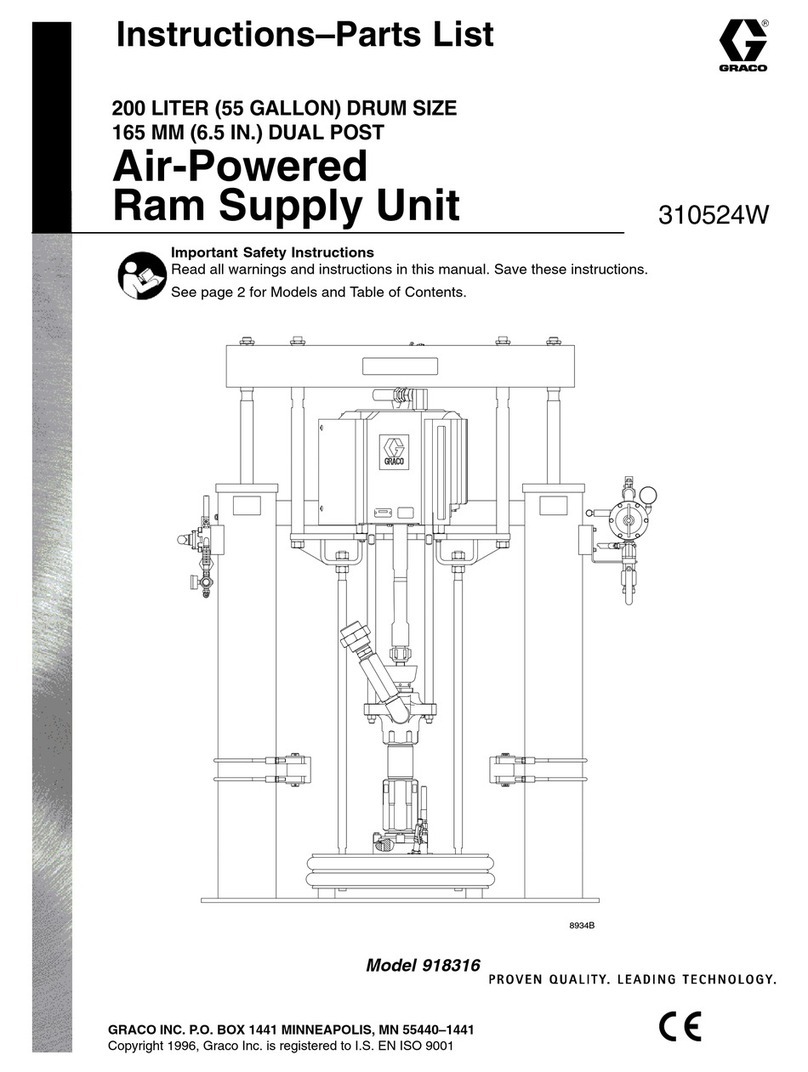

Graco 918316 Operation manual

Graco

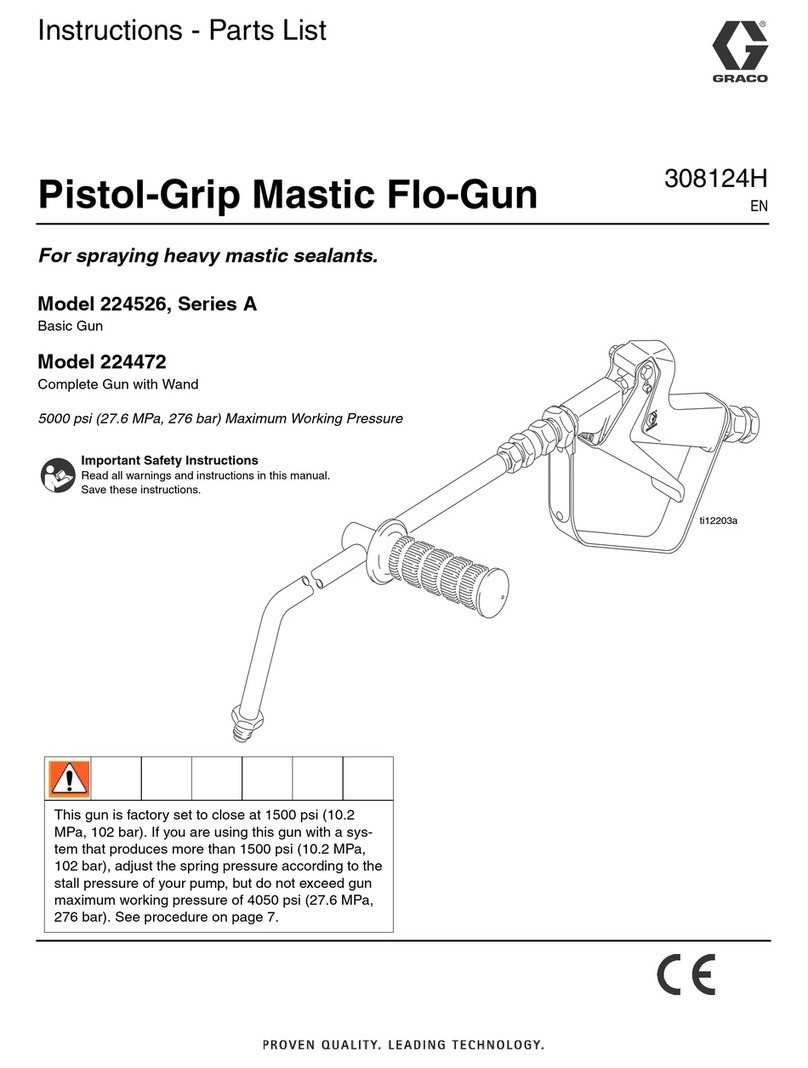

Graco Series A Operation manual

Graco

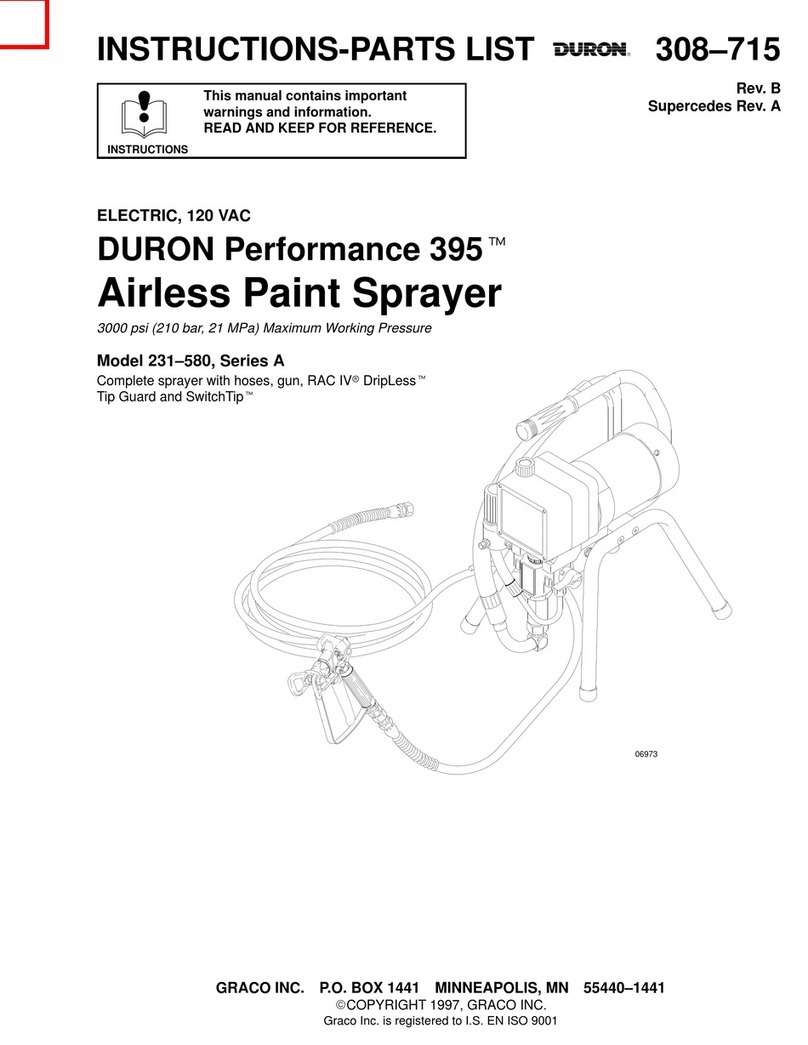

Graco DURON Performance 395 A Series Operation manual

Graco

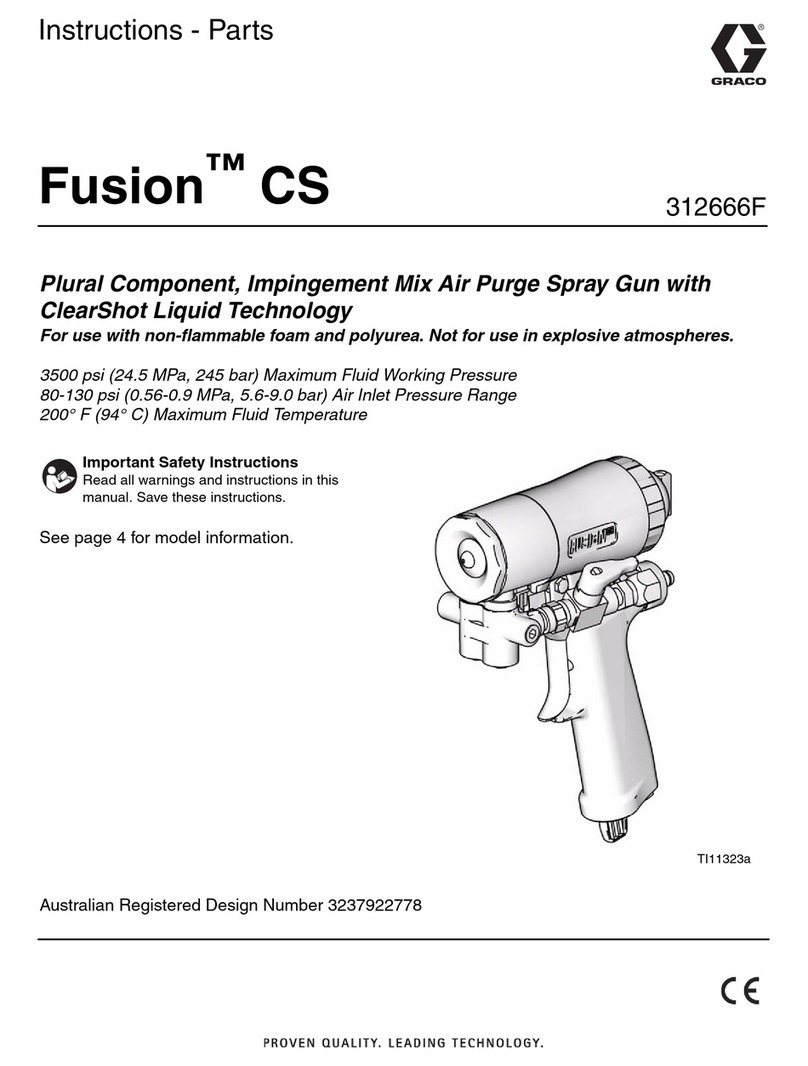

Graco Fusion CS 312666F User manual

Graco

Graco HYDRA-CLEAN C Series Operation manual

Graco

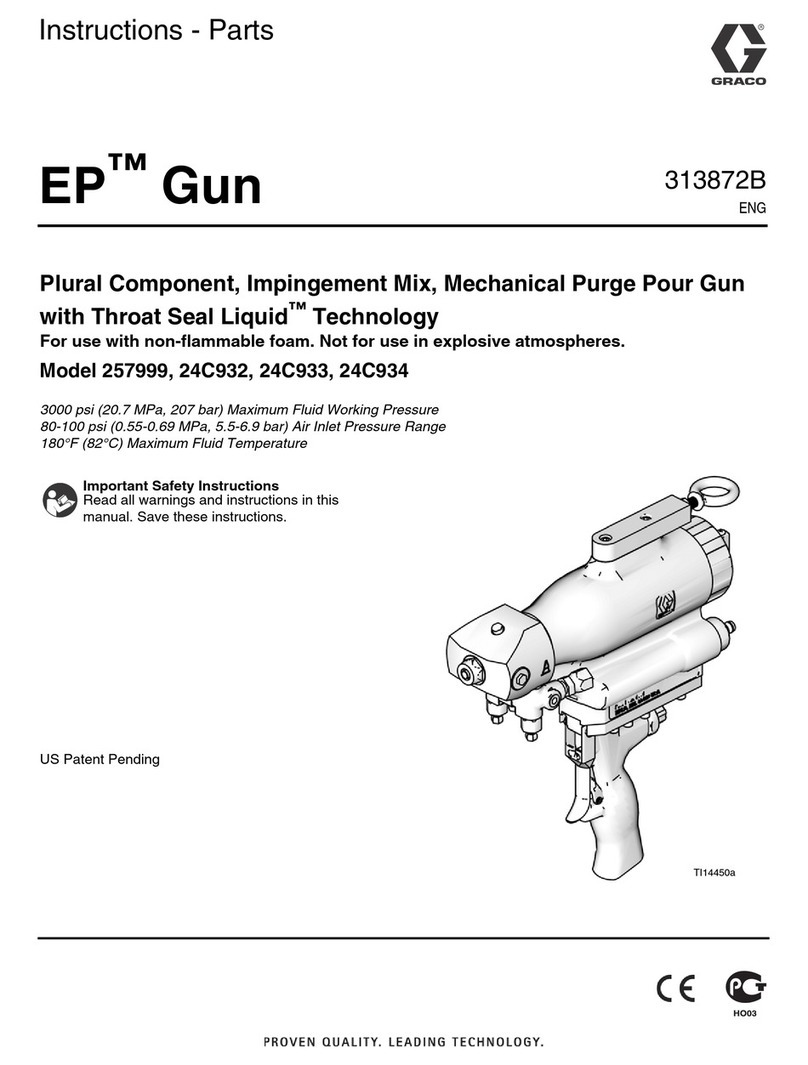

Graco EP 24C932 User manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual