Angle Grinder Safety Warning

WARNING! PERSONAL INJURY RISK Never touch the grinder or other tool while it is

moving. Do not touch the grinding wheel after operation. Grinding wheel will be very hot.

1.If the grinder jams or stalls, stop immediately. Remove the grinder from the work piece and

correct the reason for stall before continuing.

2.If tool speed drops abnormally low, begins to make abnormal noise, vibrations, or if the

motor housing produces smoke or burning odor; turn the tool off immediately and do not

operate, until repaired.

3.Hold tool by insulated gripping surfaces when performing an operation where the grinding

tool may contact hidden wiring. Contact with a "live" wire will also make exposed metal parts

of the tool "live" and shock the operator.

4. Always use proper guard with grinding wheel. A guard protects operator from

broken wheel fragments.

5. Accessories must be rated for at least the speed recommended on the tool warning label.

Wheels and

other accessories running over rated speed can fly apart

and cause injury.

2

Tool Use and Care

1.Use clamps or other practical way to secure and support the workpiece to a stable platform.

Holding the work by hand or against your body is unstable and may lead to loss of control.

2.Do not force tool.Use the correct tool for your application. The correct tool will do the job

better and safer at the rate for which it is designed.

3.Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled with the

switch is dangerous and must be repaired.

4.Disconnect the plug from the power source before making any adjustments, changing

accessories, or storing the tool. Such preventative safety measures reduce the risk of starting

the tool accidentally.

5.Store idle tools out of reach of children and other untrained persons. Tools are dangerous in

the hands of untrained users.

6.Maintain tools with care. Keep grinding tools clean. Properly maintained tools, with are less

likely to bind and are easier to control.

7.Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tools operation. If damaged, have the tool serviced before using.

Many accidents are caused by poorly maintained tools.

8.Use only accessories that are recommended by the manufacturer for your model. Accessories

that may be suitable for one tool, may become hazardous when used on another tool.

SERVICE

1.Tool service must be preformed only by qualified repair personnel. Service or maintenance

performed by unqualified personnel could result in a risk of injury.

2.When servicing a tool, use only identical replacement parts. Follow instructions in the

Maintenance section of this service manual. Use of unauthorized parts or failure to follow

Maintenance instructions may create a risk of electrical shock or injury.

SPECIFIC SAFETY RULES

WARNING: PERSONAL INJURY HAZARD.

Always use proper safety guard

with grinding wheel.

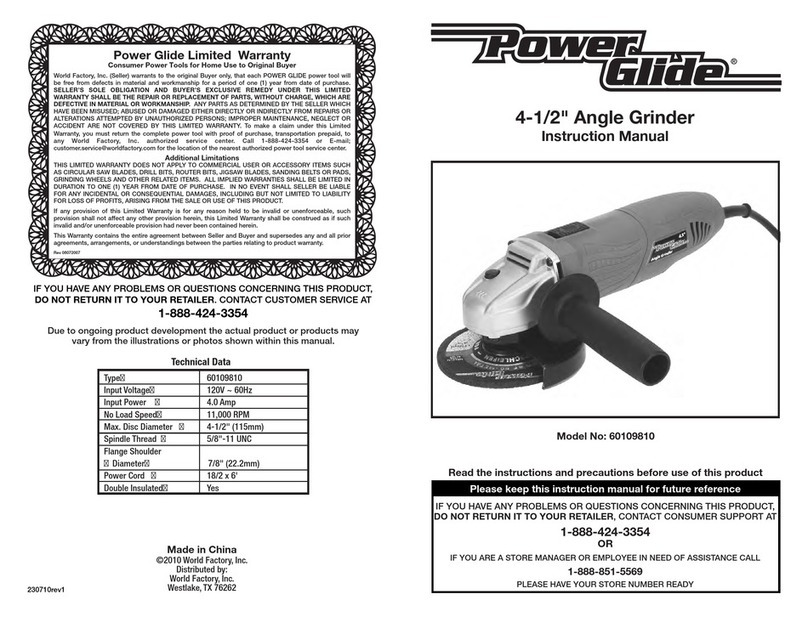

Adjusting The Wheel Guard

1.(SEE FIGURE 4) Loosen the wheel guard

clamp screw (1).

2.Align the dimple on the guard clamp ring

with the notch in the gear case cover (2).

3.Rotate the guard 180 degrees and tighten

the clamp screw (1) to secure.

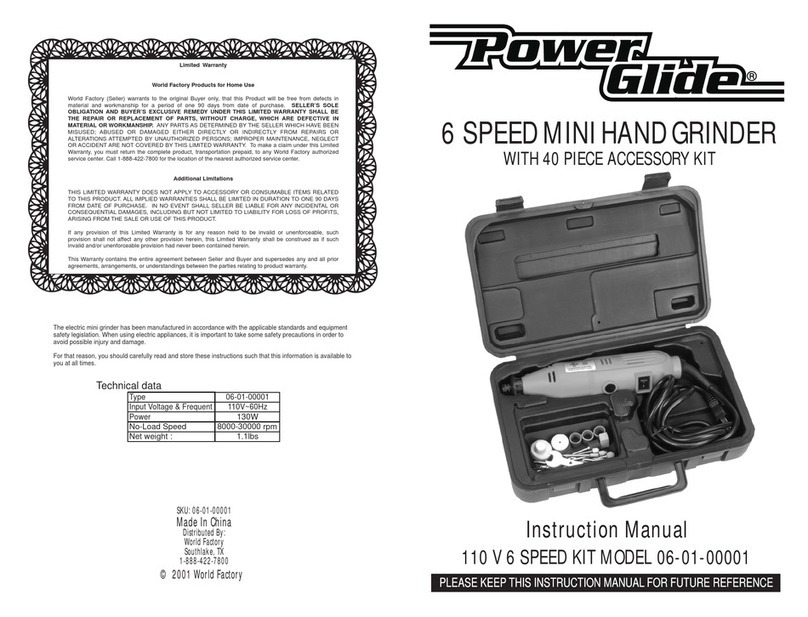

CAUTION: Do not over tighten auxiliary handle.

Damage to the handle could result.

Installing The Auxiliary Handle

NOTE: The auxiliary handle can be installed

in the left or right positions witch ever best

suits the operator and type of work.

1.(SEE FIGURE 5) Thread the handle (1) into

the left or right threaded hole in

the gear case (2).

2.By hand, rotate the handle clockwise to

tighten or counter clockwise to loosen.

1

2

1

2

Figure 4

Figure 5

1.Wheel Guard Clamp Screw

2.Gear Case Cover

1.Handle

2.Gear Case

OPERATION

3

4

WARNING: PERSONAL INJURY HAZARD.

Never touch the wheel while it is moving.

Do not touch the wheel or workpiece after

operation, it will be very hot.

1.Do not use abrasive wheels beyond their

intended life.

2.Follow wheel manufacturers instructions for

use and replacement.

Basic Operation

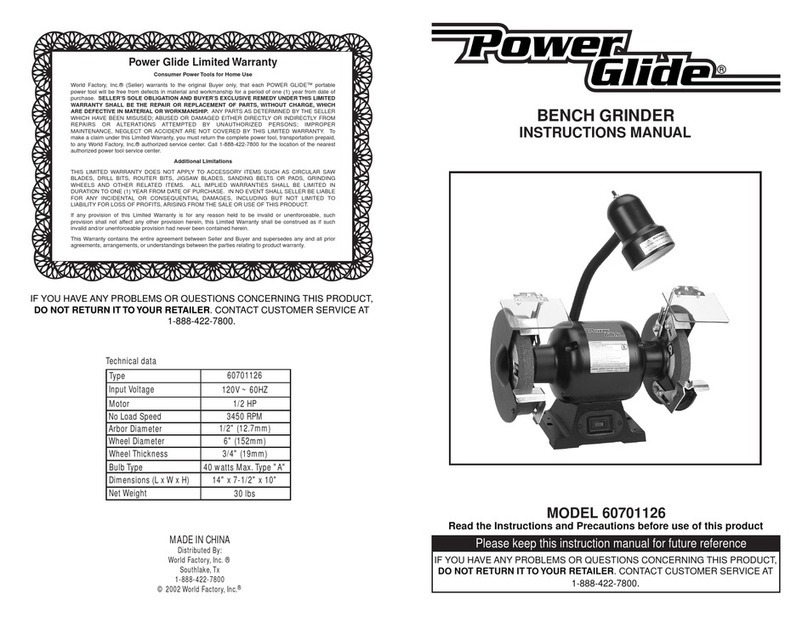

1.(SEE FIGURE 6) Hold the tool firmly by

the grip (3) and auxiliary handle (4) during

start-up and while in use.

2. Allow the tool to reach full speed before

contacting the wheel to the workpiece.

Work slowly without applying additional

pressure to the tool, its own weight is

adequate under most conditions.

Figure 6

5

3.Grip

4.Auxiliary Handle