1. Maintain Safe Working Environment.

Ensure that there is good lighting. Do not use power tools in the vicinity of combustible liquids or gases. Disorder

in the working area increases the risk of accidents.

2. Keep Other People and Pets Away From Work Area.

Do not let other people touch the tool or the power cable during operation and keep people out of your work area.

3. Store Tools in a Safe Place.

Unused tools should be stored in a dry, secure area where children cannot reach them.

4. Select the Proper Tool for the Task.

Do not use tools for any purpose other than those for which they were intended.The tool will operate more

efficiently and safely in the specified performance range. Do not use any tools or attachments that are not suited

for the work.

5. Wear Appropriate Work Clothes.

Do not wear any loose-fitting clothing or jewelry (they could get caught up in moving parts). For outdoor work, it

is recommended that you wear rubber gloves and non-slip footwear.

6. Wear ANSI Approved Safety Glasses.

Power tools can propel foreign objects and debris into your eyes.Wear ANSI Z87.1 compliant safety glasses at

all times

7. Wear a face or dust mask.

Sanding,cutting and grinding produce dust and debris that could be inhaled.

8. Secure the Work-Piece.

Use clamping devices or a vice in order to hold the work-piece in a secure position.

9. Do Not Over Reach or Stretch Beyond Your Standing Area.

Avoid any abnormal postures. Ensure that you are standing securely and keep your balance at all times while

operating a power tool.

10. Properly Maintain Your Tools.

Keep your tools ready for use in order to assure proper operation. Follow any maintenance schedule specified

and the instructions for tool changes. Check the plug and the cable regularly and if these are damaged,have

them replaced by a qualified electrical specialist. Always keep handles free from oil and grease.

11. Avoid Any Unintentional Operation or Starting-up of the Device.

Do not place your finger on the switch when carrying tools connected to the power supply. Make sure that the

switch is off when connecting the device to the power supply.

12. Disconnect the Tool From the Power Supply.

When not in use,prior to maintenance and during sand paper installation, disconnect machine tools of all kinds

from the power supply.

13.Be Alert.

Observe your work. Proceed sensibly. Do not use the tool if you are physically or mentally impaired in any manner.

Do not operate the tool under the influence of alcohol,drugs or other medication that could impair your ability.

14.Repairs Only by an Electrical Specialist.

This power tool complies with known safety regulations. Only an electrical specialist may carry out repairs.

15. Use Only Approved Accessories.

Use attachments and accessories recommended by the manufacturer for your model.Accessories that may be

suitable for one tool may become hazardous when used on another tool.

GENERAL SAFETY INSTRUCTIONS MAINTENANCE INSTRUCTIONS

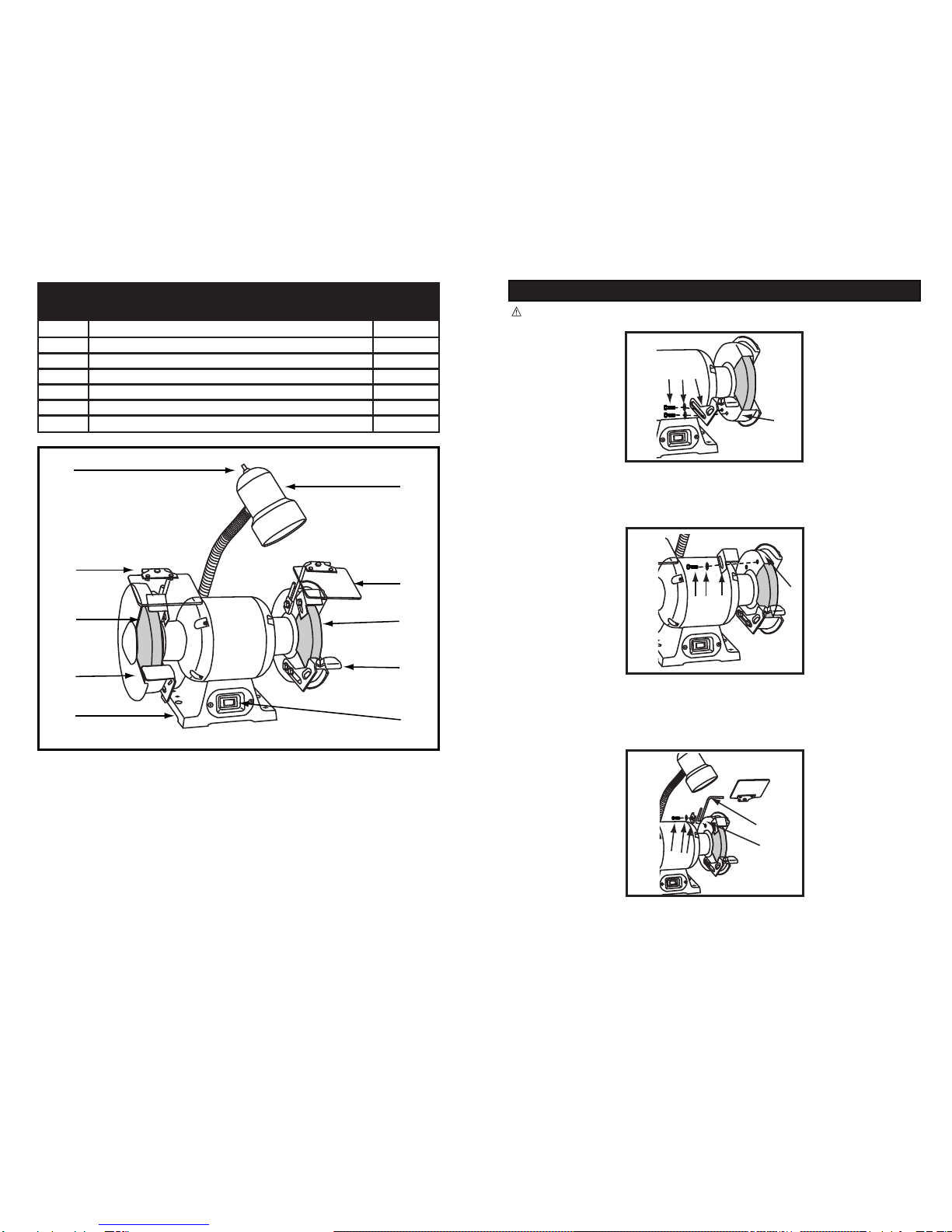

CAUTION! Tools service must be performed only by qualified repair personal. Service or maintenance performed

by unqualified personnel could result in a risk of injury. When servicing a tool,use only identical replacement

parts. Follow instruction in the maintenance section of this manual. Use of unauthorized parts or failure to follow

maintenance instructions may create a risk of electric shock or injury.

1. Clean the tool housing,grinding wheel and grinding wheel guards after each use.

2. Keep the tool dry, clean and free from oil and grease.

3. Store the tool on a safe and dry place,out of reach of children.

4. Do not use cleaning agents or solvents that could attach the plastic parts of the tool

5. Turn the tool off immediately and do not operate,until repaired, if tool begins to make abnormal noise, vibrations,

produces smoke or burning odor.

6. During normal use,grinding wheels can beecome grooved, rough,rounded at the edges or loaded with grinding

debris. Use a dressing tool (available at most hardware stores) to restore the smooth flat surface of the wheel.