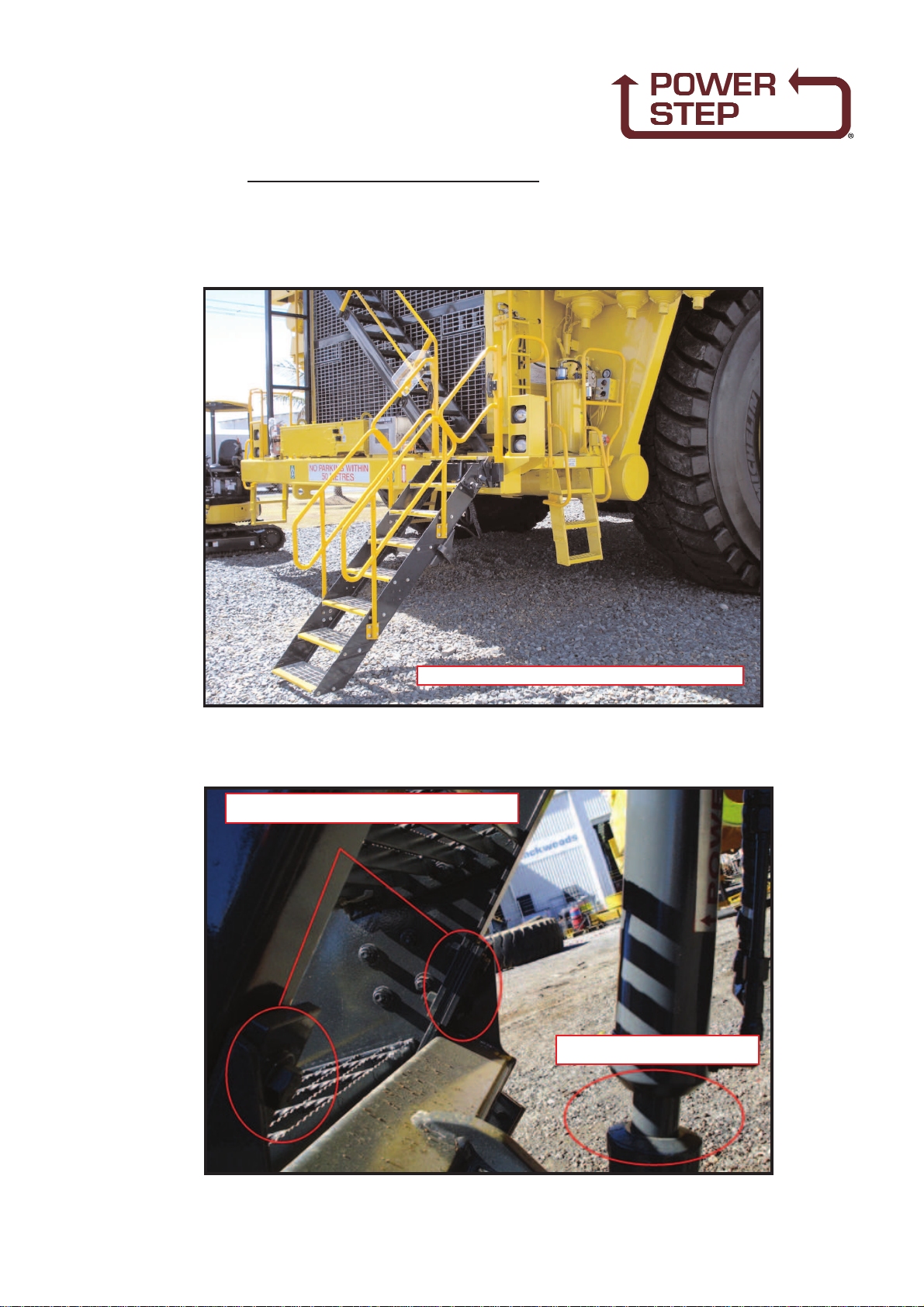

FOLDING STAIRWAY

Komatsu 960E Truck

Section 1. Mounting and Installation

See Page 4

Pg3

PSA-K960E-FS 23-1-15

PROCEDURE (Drawings 23635 & 23636)

See Drawing 23635 (Adjustments)

1. Set up the stair set with bolting faces of the landing vertical,like it will be when

installed on the truck.

2. With one of the cylinder pins removed, lower the stair to its' deployed position as

seen in View 2. Adjust the angle of inclination of the stair to 44 - 45Deg. to the

horizontal. Adjust by grinding the stop pads on both stiles or by building the stop

pads up with weld and then grinding. The bearing faces should be smooth and

flat so as not to bite into the flange plate quickly, thereby losingthe adjustment.

(This procedure should be repeated periodically during the service life of the stair

set.) Views 2 & 3.

3. Replace the cylinder pin and fully retract the cylinder. Ensure that the retracted

cylinder allows the stair to decline to the angle set in ii above. If not, adjust the

position of 23 675 Stair Actuator Attachment on the stair stile. View 2.

4. By extending the cylinder, raise the stair to the vertical stowed position. View 1.

5. Adjust the position of the Stair Buffer Bracket 23 653 on the stair stile so that the

buffer is compressed firmly when the stair is in the stowed position. View 1.

6. Adjust the positions of the Handrail Bumpers 23 651 mounted to the stair stiles and

handrail posts so they bear firmly on the handrails when the stair is stowed. These

bumpers are there to prevent vibration and rattling. View 1.

7. Adjust the position of the Go Switch Trigger 23 657 so the Go Switch creates the

appropriate connection when the stair is raised, View 4.

See Drawing 23636 (Bolting Pads)

1. Per Views 1, 2 & 3, attach the Bolting Pads to the bolt-on bumper extension at the

end of the central fixed bumper. Weld only to the extension.

2. Per View 4, fit the assembled stair set to the bolting pads, without the Landing

Deck or Landing Floor Infill fitted.

3. Per Views 5 and 6, fit the Landing Floor Infill and then the Landing Deck.

NOTE

Follow all on-site/Mine lifting and safety procedures when installing

PSFS to Truck.