About Your Water Pump ............................................................................................................ 4

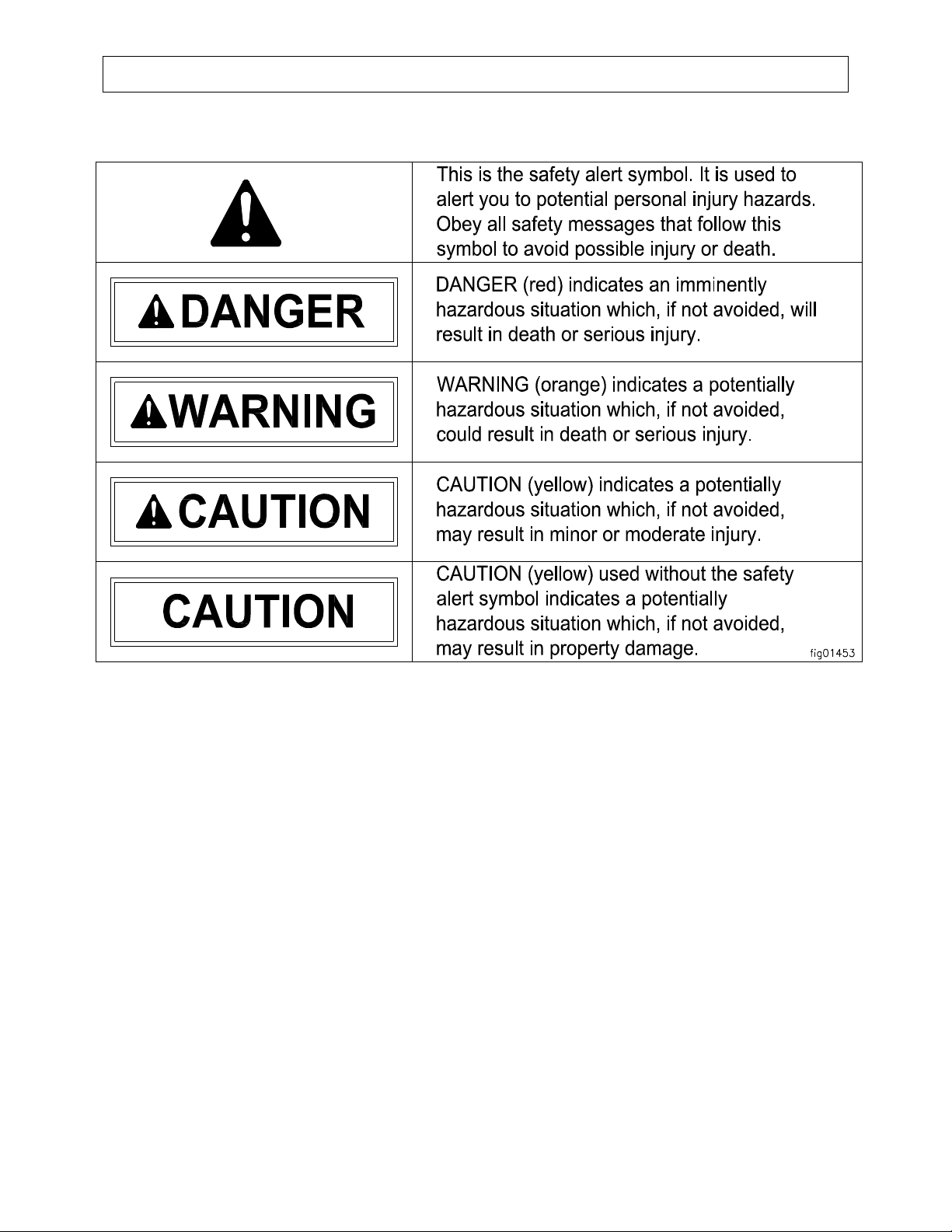

Summary of Important Safety Information................................................................................5

During Assembly

During Operation

During Storage / Troubleshooting

Warning Label Locations..............................................................................................................6

Unpacking..................................................................................................................................................8

Assembly.................................................................................................................................................................. 9

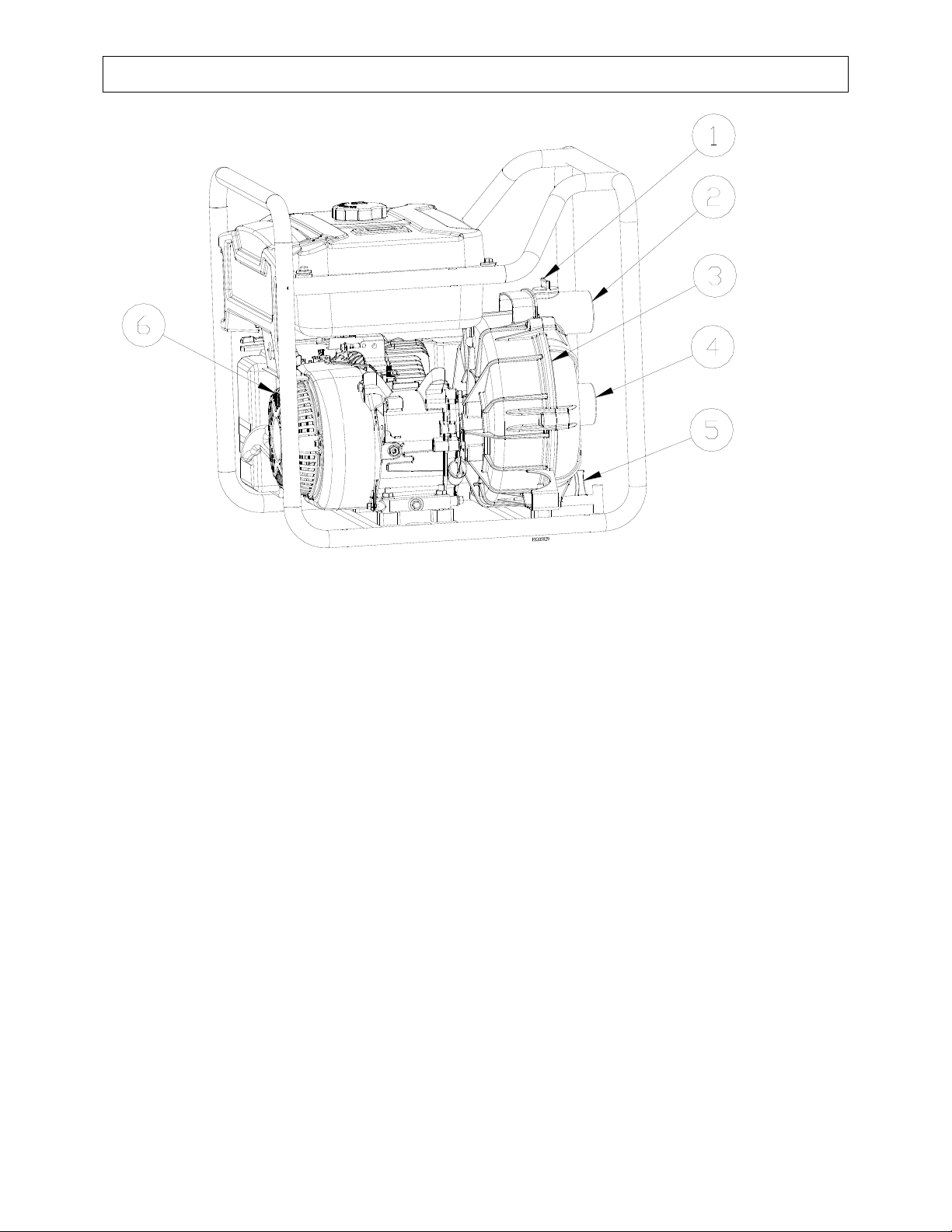

Machine Components..................................................................................................................10

Operation

Operation - Preparing the Water Pump for Each Use

Step One: Inspect/Repair...................................................................................................................11

Step Two: Select a suitable site.........................................................................................................12

Step Three: Fueling.......................................................................................................................................15

Step Four: Attach a suction strainer...........................................................................................................17

Step Five: Place the water pump.................................................................................................................17

Operation - Using the Water Pump.................................................................................................18

Storage ..........................................................................................................................................20

Troubleshooting ...........................................................................................................................21

Specifications................................................................................................................................22

Water Pump Exploded View.......................................................................................................23

750126 Pump Exploded View .....................................................................................................24

Engine Exploded View.................................................................................................................25

Engine Operation/Specs ..............................................................................................................28

Engine Maintenance ....................................................................................................................29

Engine Storage .............................................................................................................................32

Limited Warranty........................................................................................................................33

California Proposition 65 Information ......................................................................................34