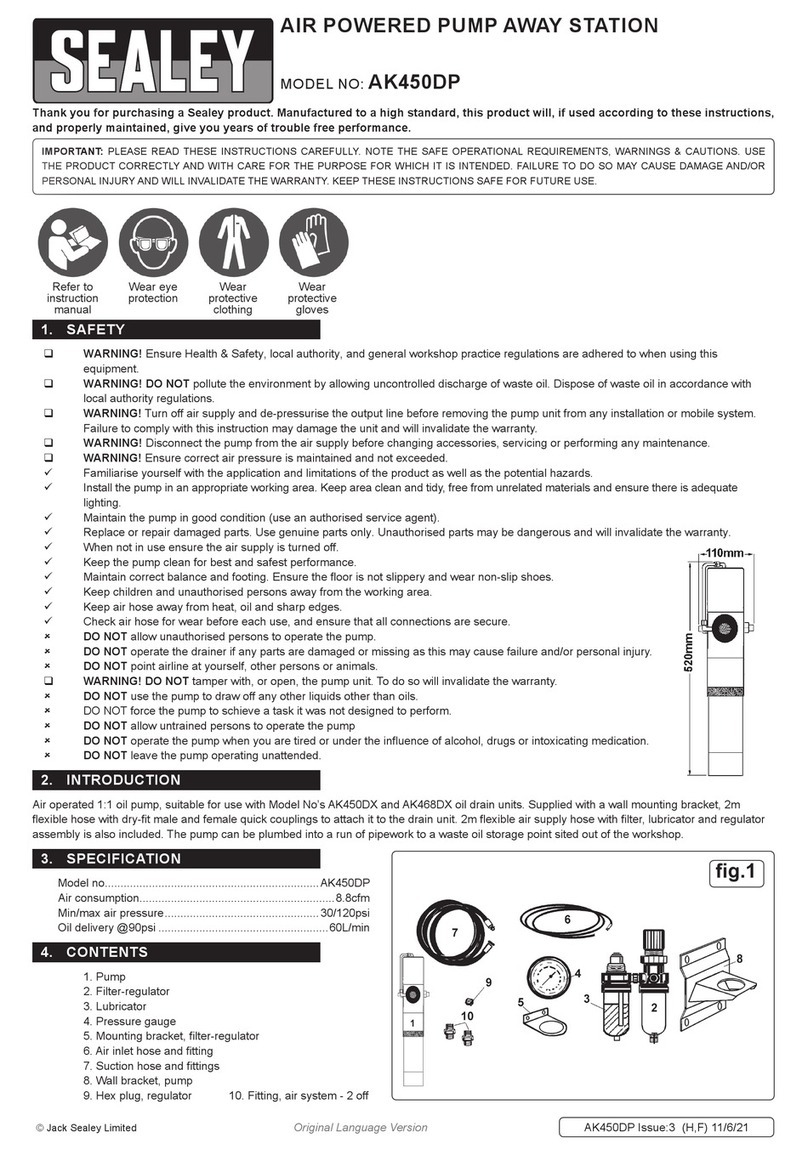

INTRODUCTION

This instruction sheet provides you with the information required to safely own

and operate your product. Retain these instructions for future reference.

The product you have purchased is of the highest quality workmanship and

material, and has been engineered to give you long and reliable service. This

product has been carefully tested, inspected, and packaged to ensure safe

delivery and operation. Please examine your item(s) carefully to ensure that no

damage occurred during shipment. If damage has occurred, please contact the

place of purchase. They will assist you in replacement or repair, if required.

READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING

TO INSTALL, OPERATE, OR SERVICE YOUR PRODUCT. KNOW THE

PRODUCT’S APPLICATION, LIMITATIONS, AND POTENTIAL HAZARDS.

PROTECT YOURSELF AND OTHERS BY OBSERVING ALL SAFETY

INFORMATION. FAILURE TO COMPLY WITH THESE INSTRUCTIONS

COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE!

DESCRIPTION

Little Giant Submersible Sewage Ejector Pumps are recommended for use in

basins or lift stations and suitable for pumping sewage, effluent, wastewater

and other non-explosive, non-corrosive liquids with up to 2” spherical solids.

Automatic operation can be achieved with the use of the RFS Remote Float Switch.

Other accessories such as basins, check valves and covers are also available.

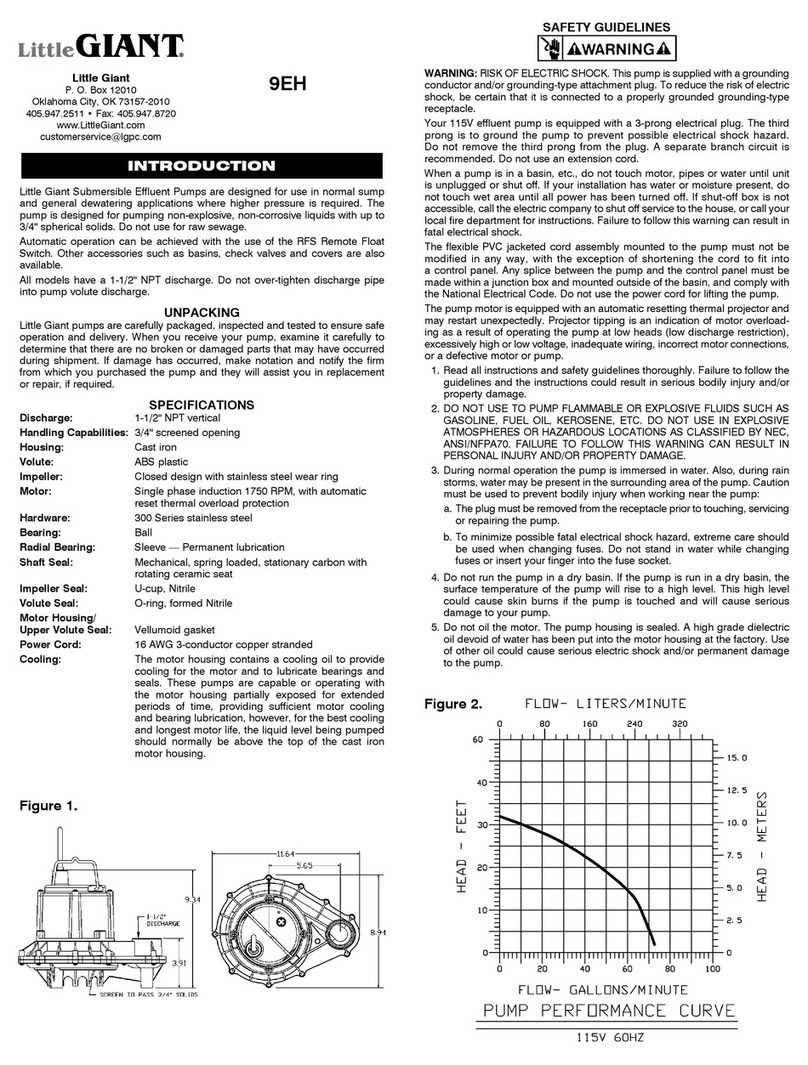

SPECIFICATIONS

Discharge: 2” or 3” NPT vertical

Intake: 2” diameter opening

Housing: Cast iron

Volute: Cast iron

Impeller: Vortex design with pressure relief vanes

Motor: Single-phase induction 1750 RPM with automatic reset

thermal overload protection

Hardware: 300 series stainless steel

Thrust Bearing: Ball

Radial Bearing: Sleeve – permanent lubrication

Shaft Seal: Mechanical, spring loaded, stationary carbon with rotating

ceramic seat

Power Cord: 16 AWG 3-conductor copper stranded

Cooling: The motor housing contains a cooling oil to provide cooling

for the motor and to lubricate bearings and seals. These pumps

are capable of operating with the motor housing partially

exposed for extended periods of time, providing sufficient motor

cooling and bearing lubrication, however, for the best cooing

and longest motor life, the liquid level being pumped should

normally be above the top of the cast iron motor housing.

SAFETY GUIDELINES

WARNING: RISK OF ELECTRIC SHOCK. This pump is supplied with a

grounding conductor and/or grounding-type attachment plug. To reduce the

risk of electric shock, be certain that it is connected to a properly grounded

grounding-type receptacle.

Your 115V sewage ejector pump is equipped with a 3-prong electrical plug.

The third prong is to ground the pump to prevent possible electrical shock

hazard. Do not remove the third prong from the plug. A separate branch circuit

is recommended. Do not use an extension cord.

When a pump is in a basin, etc., do not touch motor, pipes or water until unit

is unplugged or shut off. If your installation has water or moisture present,

do not touch wet area until all power has been turned off. If shut-off box is not

accessible, call the electric company to shut off service to the house, or call

your local fire department for instructions. Failure to follow this warning can

result in fatal electrical shock.

The flexible PVC jacketed cord assembly mounted to the pump must not be

modified in any way, with the exception of shortening the cord to fit into a

control panel. Any splice between the pump and the control panel must be

made within a junction box and mounted outside of the basin, and comply with

the National Electrical Code. Do not use the power cord for lifting the pump.

The pump motor is equipped with an automatic resetting thermal protector and

may restart unexpectedly. Protector tripping is an indication of motor overloading

as a result of operating the pump at low heads (low discharge restriction), excessively

high or low voltage, inadequate wiring, incorrect motor connections, or a defective

motor or pump.

1. Read all instructions and safety guidelines thoroughly. Failure to follow the

guidelines and the instructions could result in serious bodily injury and/or

property damage.

2. DO NOT USE TO PUMP FLAMMABLE OR EXPLOSIVE FLUIDS SUCH AS

GASOLINE, FUEL OIL, KEROSENE, ETC. DO NOT USE IN EXPLOSIVE

ATMOSPHERES OR HAZARDOUS LOCATIONS AS CLASSIFIED BY NEC,

ANSI/NFPA70. FAILURE TO FOLLOW THIS WARNING CAN RESULT IN

PERSONAL INJURY AND/OR PROPERTY DAMAGE.

3. During normal operation the pump is immersed in water. Also, during rain

storms, water may be present in the surrounding area of the pump. Caution

must be used to prevent bodily injury when working near the pump:

a. The plug must be removed from the receptacle prior to touching, servicing

or repairing the pump.

b. To minimize possible fatal electrical shock hazard, extreme care should

be used when changing fuses. Do not stand in water while changing

fuses or insert your finger into the fuse socket.

4. Do not run the pump in a dry basin. If the pump is run in a dry basin, the

surface temperature of the pump will rise to a high level. This high level

could cause skin burns if the pump is touched and will cause serious

damage to your pump.

5. Do not oil the motor. The pump housing is sealed. A high grade dielectric

oil devoid of water has been put into the motor housing at the factory. Use

of other oil could cause serious electric shock and/or permanent damage

to the pump.

6. This pump’s motor housing is filled with a dielectric lubricant at the factory

for optimum motor heat transfer and lifetime lubrication of the bearings.

Use of any other lubricant could cause damage and void the warranty.

This lubricant is non-toxic; however, if it escapes the motor housing, it

should be removed from the surface quickly by placing newspapers or

other absorbent material on the water surface to soak it up, so aquatic life

is undisturbed.

7. In any installation where property damage and/or personal injury might result from

an inoperative or leaking pump due to power outages, discharge line blockage, or

any other reason, a backup system(s) and/or alarm should be used.

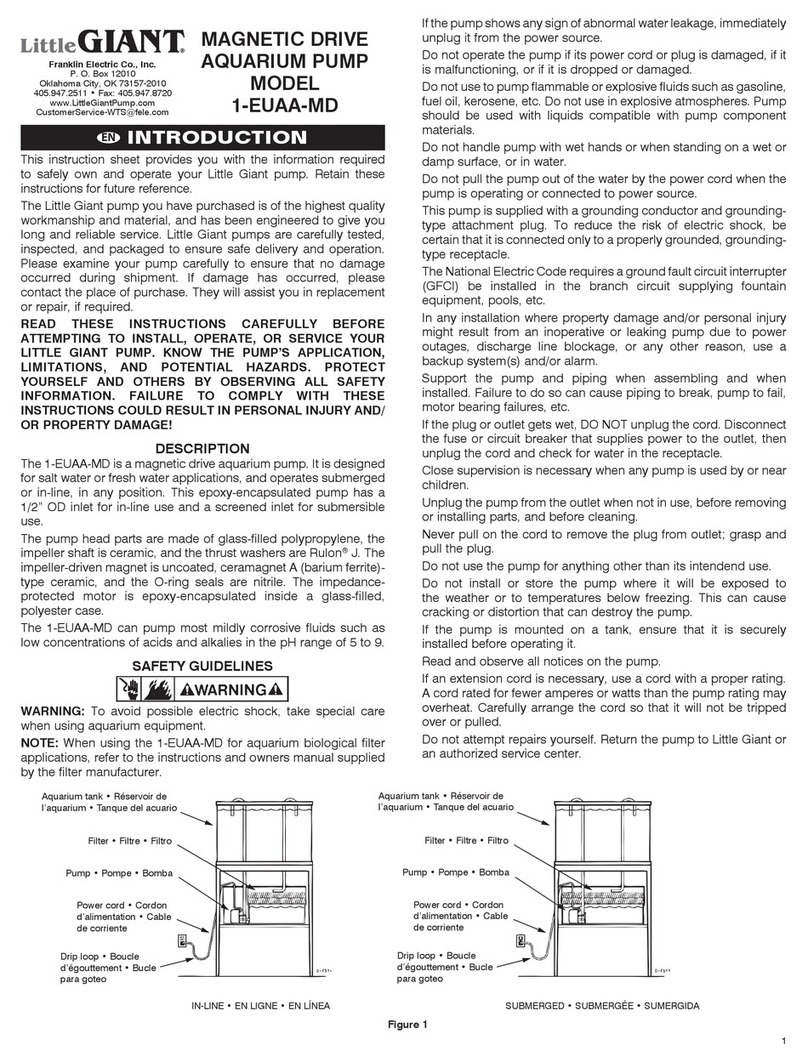

INSTALLATION

Pump must be installed in a suitable gas-tight basin which is at least 18” in

diameter and 24” deep, and vented in accordance with local plumbing codes.

Pump features a 2” or 3” female NPT discharge.

Pump can be installed with ABS, PVC, polyethylene or galvanized steel pipe.

1

9S-CIM

9S-CIA-RFS

Submersible

Sewage Ejector Pump

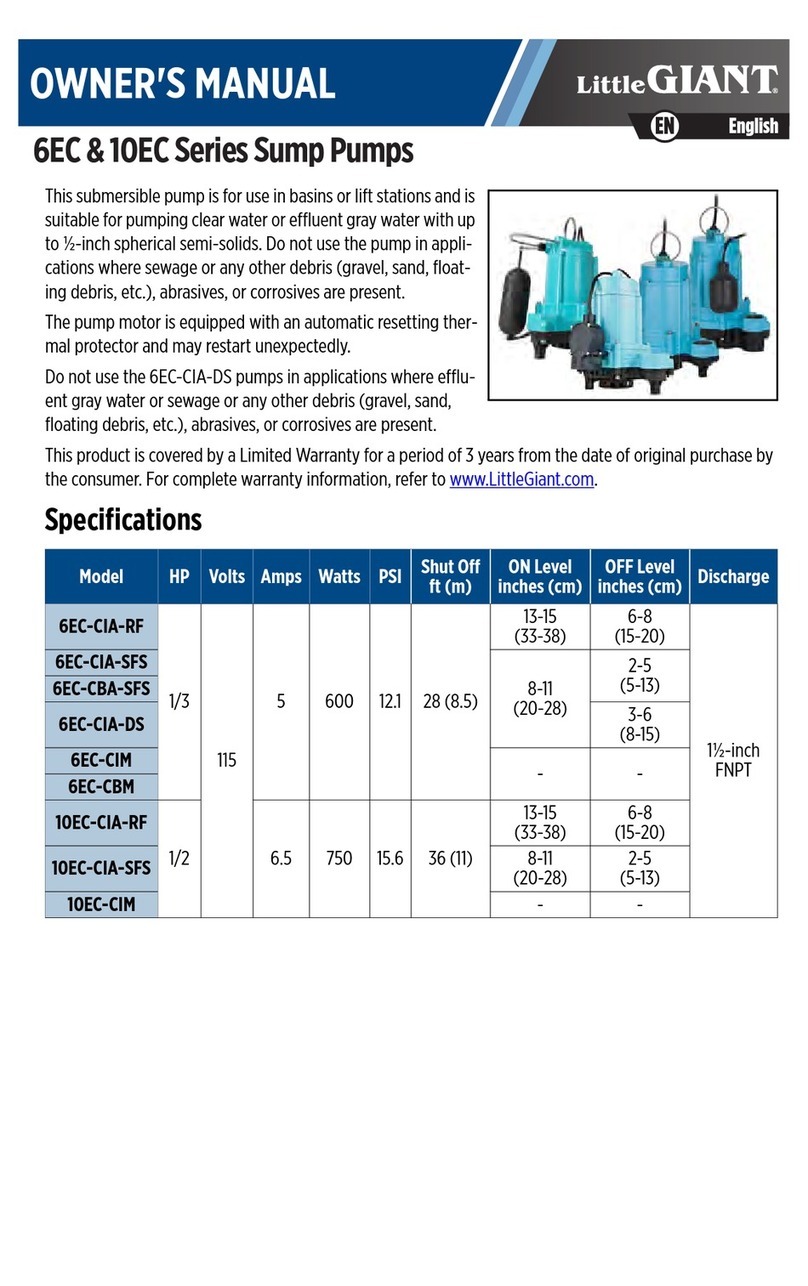

MODEL NO. LISTING VOLTS HP AMPS/ WATTS

GPM @ HEAD

SHUT OFF (ft.) P.S.I. PWR CRD (ft.) WT. (lbs.)

5’ 10’ 15’

9S-CIM UL 115 4/10 13.0/1015 80 50 16 18.0 7.8 15 33

9S-CIM — 230 4/10 6.5/1120 80 50 16 18.0 7.8 15 33

9S-CIA-RFS UL 115 4/10 13.0/1015 80 50 16 18.0 7.8 15 34

Figure 1

Franklin Electric Co., Inc.

P. O. Box 12010

Oklahoma City, OK 73157-2010

405.947.2511 • Fax: 405.947.8720

www.LittleGiantPump.com