2

TABLE OF CONTENTS

TABLE OF CONTENTS ................................................ .................................................. .................................................. .................... 2

SYMBOLS WARNING / INFORMATION .............................................. .................................................. .................. 4

PURPOSE OF THE DEVICE ................................................ .................................................. ........................................ 5

SAFETY ................................................. .................................................. .................................................. ........ 6

Safety during welding ............................................... .................................................. .............................. 6

General safety ............................................... .................................................. ............................. 8

Protection against electric shock .............................................. .................................................. ................... 8

Electromagnetic field ................................................ .................................................. ........................................... 9

Pacemakers ................................................ .................................................. .................................................. ....... 9

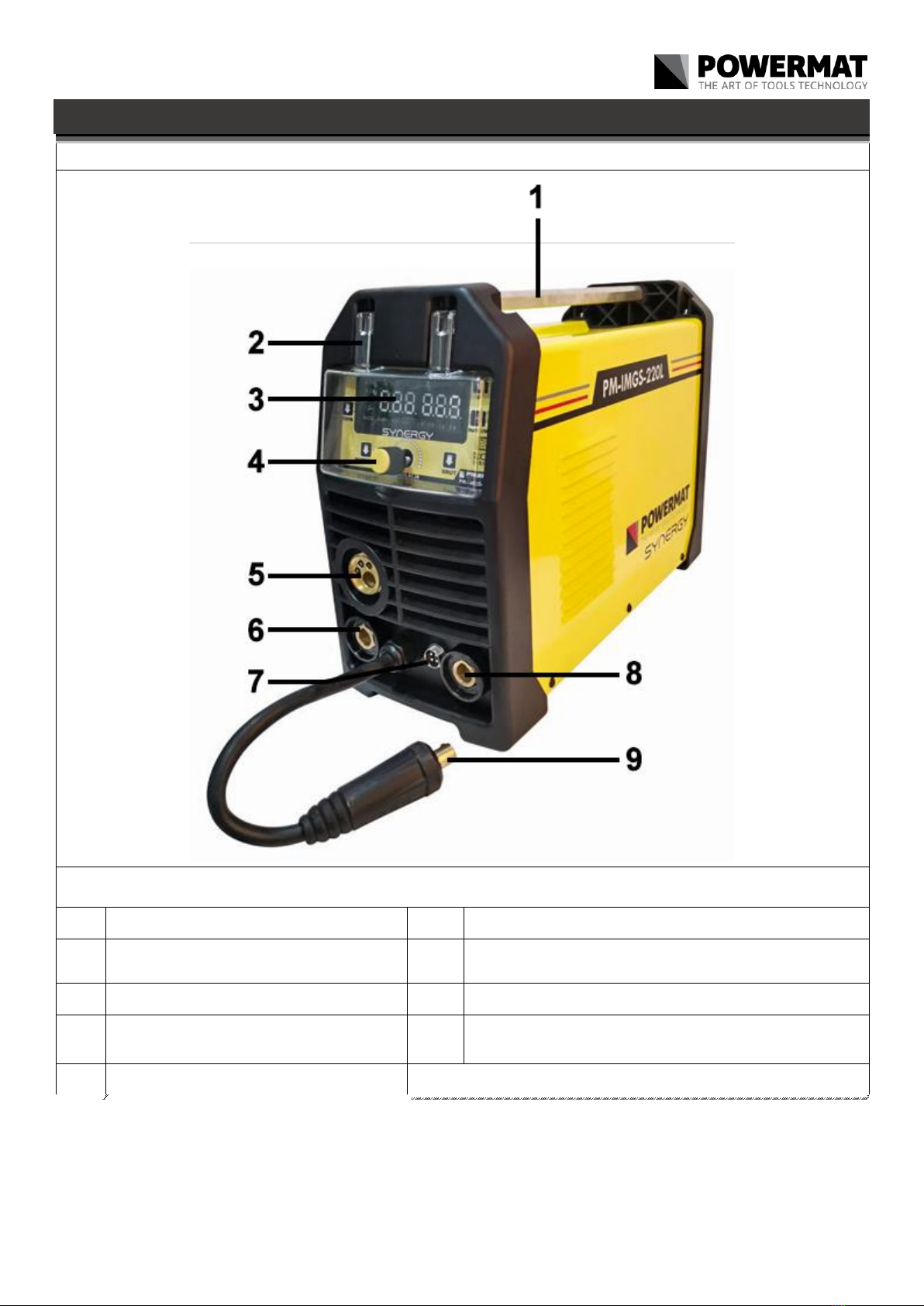

DESCRIPTION OF THE DEVICE ................................................ .................................................. .................................................. ....... 10

DESCRIPTION OF SYMBOLS ON THE LABEL ............................................. .................................................. ............. 12

TECHNICAL DATA ................................................ .................................................. .................................................. ...... 13

GENERAL WORKING CONDITIONS MACHINE ............................................. .................................................. ................... 13

General thoughts ................................................ .................................................. .................................................. .......... 13

Basic steps before you begin working ............................................. .................................................. ..... 14

During welding operations ............................................... .................................................. ..................................... 14

Prohibited Actions ................................................ .................................................. ............................................... 14

Basic activities after work ............................................. .................................................. ............. 14

Final remarks ................................................ .................................................. .................................................. ....... 15

USING THE MACHINE ................................................ .................................................. ............................................... 15

Connecting to the network ............................................... .................................................. .................................................. . 15

Inserting the wire electrode ............................................... .................................................. ............................... 15

Connection of protective gas ............................................... .................................................. ................................... 16

Welding MMA ............................................... .................................................. ............................................ 16

MAG welding in manual mode ............................................ .................................................. .............. 16

Welding by TIG-LIFT ............................................. .................................................. .......................................... 16

Welding wire holder magazine (spool gun) ......................................... .................................................. . 17

Control panel ................................................ .................................................. .................................................. ..... 18

BASIC INFORMATION FOR WELDING .............................................. .................................................. .. twenty

WELDING ELECTRODES IN PRACTICE .............................................. .................................................. ......................... twenty

Electric arc welding ............................................... .................................................. .................................. 21

Selection of appropriate electrode ............................................... .................................................. .................................. 21

Correct welding position ............................................... .................................................. ................................... 22

Tips arc ignition .............................................. .................................................. ............................... 22

Proper arc length ............................................... .................................................. ........................................... 23