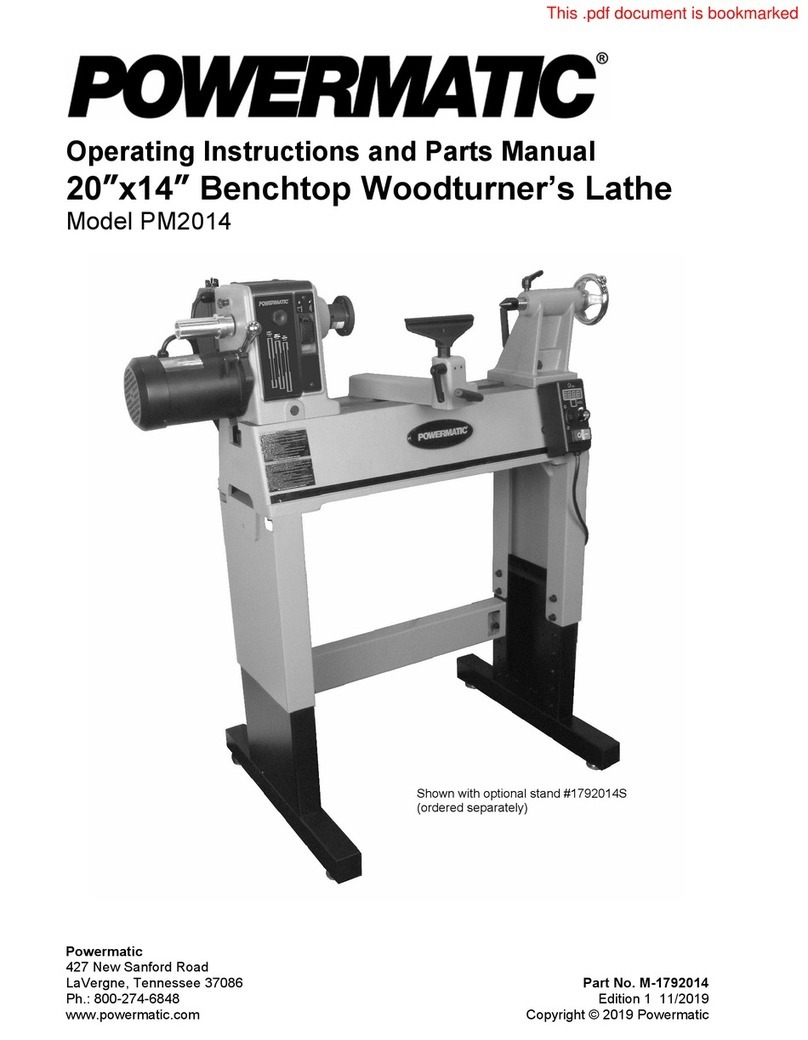

MODEL45

- 12"

(3o4.amm)

WOODLATHE MAINTENANCE

INSTRUCTIONS

II

l

I

a

FOREWORD

SAFETY

FIRST!

This

manual

has

been

prepared

for theownerandthose

responsiblefor the

maintenance

of aPowermatic

wood-turninglathe.

Its

purpose,

aside

from machine

maintenanceisto promote

safetythroughthe use

of accepted

operating

practices.

Read

thesafety

andoperatinginstructions

thoroughly

before

operatingthe machine.

Inorderto obtainmaximum

life

andefficiencyfrom yourPowermatic

lathe

andto aidin

operating

the

lathewith safety,read

the operating

and

maintenance

instructions

thoroughly

and

follow

alldirections

carefully.

The

specificationslistedwere

ineffect

whenthemanual

was

published.

However,

because

of Powermatic's

policy

of continuousimprovement,Powermatic

, Inc.,reserves

theright

to changespecifications

atanytimewithout notice

andvrithoutincurring

obligations.

WARRANTY

Ponnermatic,

a Division

ol StanwichIndustries,

Inc.,

Morrison Road,

McMinnville,Tennessee

371IO

("powermarrc")

warranls to its authorizeddistribulors

of Powermatic

producls

andthe original

purchasers

for suchdistributors,

all

products

manufactured

by Powermatic

to befreeol defects

in material

andworkmanship

for a period

of welve (12)

monthsfrom thedateof deliveryfrom itsauthorizeddistributorsor 2@ hours

of use,whichever

occursfirst.

During

saidwarranty period

Powermalic

will, at itsoplion,repair

or replace

any

product(or

componenl

part

thereot

proving

defective

duringsaid

period.

Thiswarranty

appliesonlyto products

whichareused

in

accordance

with att

instructioni

astooperation,maintenance

andsatetyselforthinthecatalogs,manuals,

andlor inslruclaon

selsturnrshed

by

Power-

matic.

Thiswarrantybecomes

effective

ontyif the accompanying

card

isfullyandproperly

completed

andreturned

to

Powermatic

within ten (lOl daysfrom dateof deliveryto the originalpurchaser.

Thiswarranty doesnot applyto ilems that would normallybeconsumed

or requirereplacemenl

dueto normal

wear

{blades,

lubricants,

etc.};lo electricalmotors

andcomponentswhich arewarranted

bytheirmanutacturer;

orthe

costs

of removal,

shipment

for serviceand reinstallation.

Claimsrelatinglo electrical

conponents must be taken to the

componentmanufacturer's

local

authorizedrepairstation

for service.

Thiswarranty is null andvoid if the product

hasbeensubjectedto (l) misuse,

abuse

or improper

servrceor srorage;

(2) accident,

neglect,

damage

or other circumslances

beyondPowermatic's

control;

(31

modifications.

disassembly

tampering,

alterations

or repairs

outsideof Povrrcrmatic's

faclorynotauthorizedbyPowermatic;

or to anyproducl

not

bearingitsoriginal

serial

number

plate.

Thiswarrantydoes

not apply

to normalvrrrear

andtear,corrosion,

abrasion.

or

repairs

required

due to naluralcauses

or actsof God.

Toobtainthe fastest

possible

warranty service

you musl first notifyinwriting theauthorized

Powermatic

distributor

fromwhom youpurchased

theproduct

specifying

(

1

)

theproduct

by

catalognumber

andserral

Oumber,

{2)

thedate

the

product

wasdelrvered

to you,

(3)

adescription

of the problem

for which you

seekwarranlyservice,

and

(4)

evrdence

of

proofof purchase.

Shouldcircumslances

prohibityoucontaclingthe distribulorlhen contact

the Powermatic

factory

directly.lfyour

claimis

coveredbythiswarranty,

your

Powermatrc

distributorwillprovideyou

with instructions

asto

howandwhere

servicewillbe

provided.

Onsimple

warranty

replacemenl

orrepairs,installalions

instructions

wtll

be

provided

to allow correclionby customer

personnel.

Porrermalicassumes

no responsibility

{or products

which are

relurnedwrthout

its

prior

wrinen

authonzation.

Powermalic's

obligation

under

thiswarranty

shallbe

exclusrvelylrmited

to repairing

orreplacing

(at

Powermalic's

option)

products

whicharedetermrned

by

Powermatic

tobe

defective

upon

delivery,FO.B.

(return

freight paidby

customer)

Powermalic'sfactory,

andon inspection

byPowermatic.

In noevent

shall

Powermatic's

liability

underthiswarranty

exceedthepurchaseprice

paid

for

theproduct.

THIS

ISPOWERMATIC'S

SOLE

WRITTENWARRANW.ANYANDALL

OTHER

WARRANTIES

WHTCH

MAY

BEIMPLIED

BYLAW, INCLUDING

ANYWARRANTIESFORMERCHANTAEILITY

OR

FITNESS

FORA PARTICUI-AR

PURPOSE,

ARE

HEREBYLIMTTEDTO

THEDURATION

OF

THISWRTTTENWARRANW,POWERMATIC

SHALLNOT

BELIAELEFOR

ANY

LOSS,DAMAGE,

OR

EXPENSESDIRECTLY

OR

INDIRECTLYREI-ATEDTOTHE

USEOFITSPRODUCTS

OR

FROM

ANY

OTHER

CAUSE

OR

FOR

CONSEOUENTIALDAMAGES

(INCLUDING

WITHOUT

LIMITATION,

LOSS

OF

TIM€,

INCON.

VENIENCE,ANDLOSS

OF

PRODUCTION).

THEWARRANWCONTAINED

HEREINMAYNOT

BEMODIFIEO

AND

NO

OTHER

WARRANW, EXPRESSOR IMPUED,

SHALL

8E MADE BYORON EEHALF

OFPOWERMATIC

i

I

I

2