3

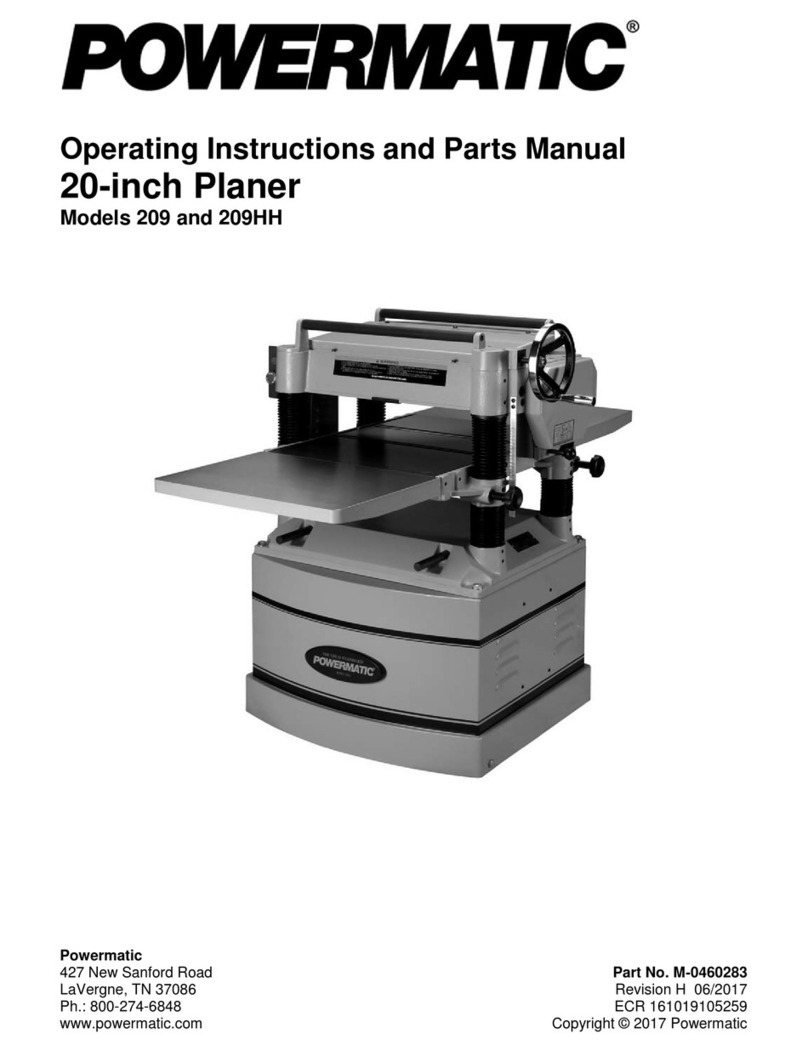

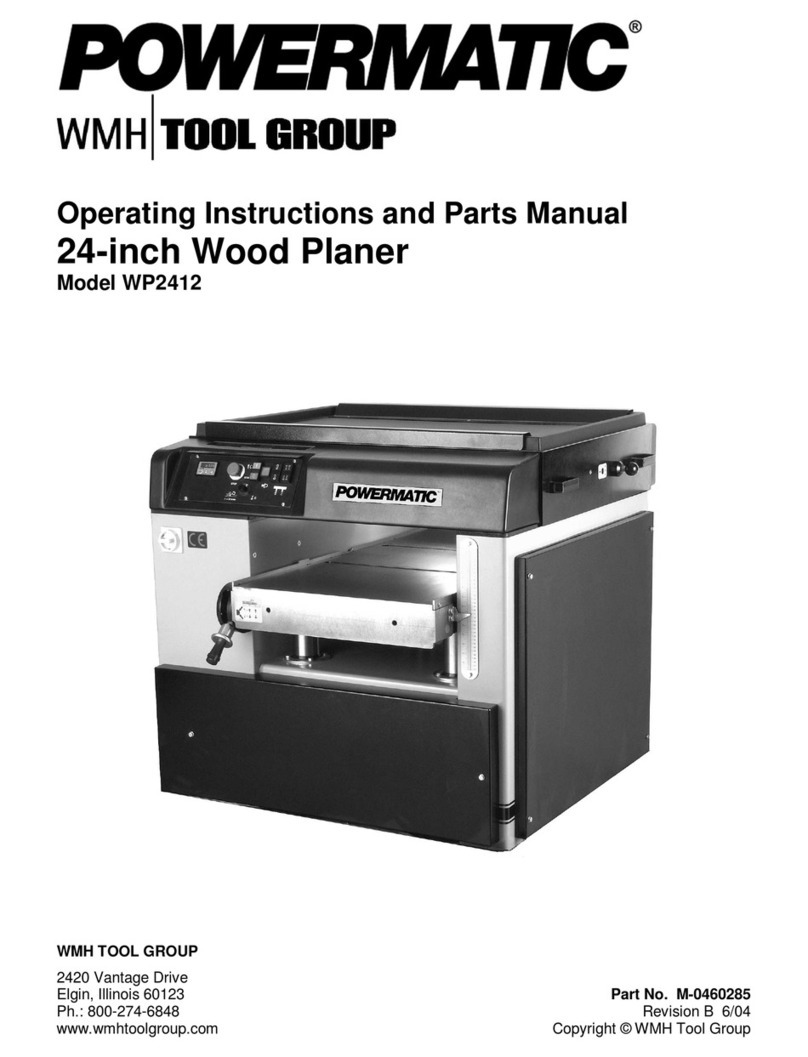

TABLE OF CONTENTS

Safety Rules.......................................................................................................................................... 4-5

Safety Decals........................................................................................................................................... 6

Features................................................................................................................................................... 7

Specifications........................................................................................................................................... 8

Receiving................................................................................................................................................. 9

Installation & Assembly............................................................................................................................10

Handwheel ........................................................................................................................................10

Starter Box........................................................................................................................................11

Extension Tables...............................................................................................................................11

Dust Hood.........................................................................................................................................11

Electrical Connections.......................................................................................................................12

Extension Cords................................................................................................................................12

Adjustments.............................................................................................................................................13

Belt Tension......................................................................................................................................13

Pulley Alignment ...............................................................................................................................13

Table Rollers.....................................................................................................................................14

Cutterhead ........................................................................................................................................15

Replacing Knives ..............................................................................................................................15

Work Table Parallel to Cutterhead.....................................................................................................16

Know the Transmitting Rollers of Your Planer....................................................................................17

Anti-Kickback Fingers........................................................................................................................17

Infeed & Outfeed Roller Spring Tension ............................................................................................18

Height of Infeed Roller, Chipbreaker, & Outfeed Roller......................................................................18

Outfeed Roller Height........................................................................................................................19

Infeed Roller Height...........................................................................................................................19

Chipbreaker Height............................................................................................................................19

Chip Deflector...................................................................................................................................20

Feed Speed Control ..........................................................................................................................20

Changing Accessories for Lowest Feed Speed..................................................................................20

Stock Return Rollers..........................................................................................................................21

Depth of Cut......................................................................................................................................21

Maintenance............................................................................................................................................22

Lubrication ........................................................................................................................................22

Gearbox Lubricant.............................................................................................................................23

Functions of the Digital Scale..................................................................................................................24

Calibrating & Using Digital Scale.............................................................................................................25

Optional Accessories...............................................................................................................................27

Trouble-Shooting: Digital Scale ...............................................................................................................27

Trouble-Shooting: Performance Problems...............................................................................................28

Trouble-Shooting:Mechanical & Electrical Problems...........................................................................29-30

Replacement Parts & Service..................................................................................................................31

Parts Lists & Exploded Views:

Base Assembly.............................................................................................................................32-33

Table Assembly............................................................................................................................34-35

Gearbox Assembly.......................................................................................................................36-37

Cabinet Assembly ........................................................................................................................38-39

Head Assembly............................................................................................................................40-42

Electrical Schematic................................................................................................................................43

Maintenance Checklist.............................................................................................................................44